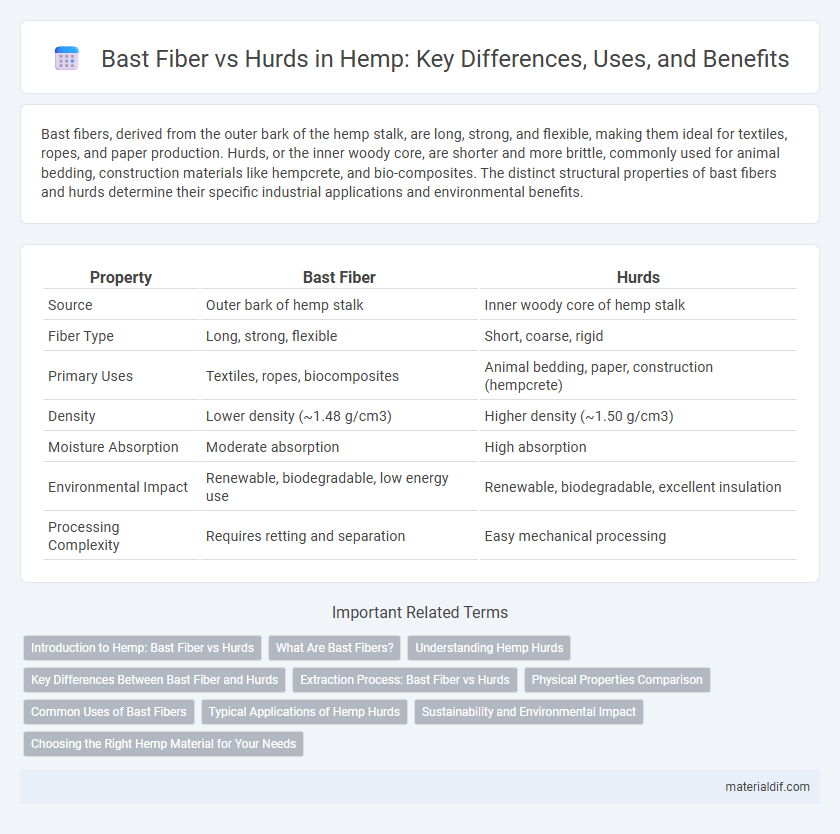

Bast fibers, derived from the outer bark of the hemp stalk, are long, strong, and flexible, making them ideal for textiles, ropes, and paper production. Hurds, or the inner woody core, are shorter and more brittle, commonly used for animal bedding, construction materials like hempcrete, and bio-composites. The distinct structural properties of bast fibers and hurds determine their specific industrial applications and environmental benefits.

Table of Comparison

| Property | Bast Fiber | Hurds |

|---|---|---|

| Source | Outer bark of hemp stalk | Inner woody core of hemp stalk |

| Fiber Type | Long, strong, flexible | Short, coarse, rigid |

| Primary Uses | Textiles, ropes, biocomposites | Animal bedding, paper, construction (hempcrete) |

| Density | Lower density (~1.48 g/cm3) | Higher density (~1.50 g/cm3) |

| Moisture Absorption | Moderate absorption | High absorption |

| Environmental Impact | Renewable, biodegradable, low energy use | Renewable, biodegradable, excellent insulation |

| Processing Complexity | Requires retting and separation | Easy mechanical processing |

Introduction to Hemp: Bast Fiber vs Hurds

Hemp consists of two primary components: bast fiber and hurds, which differ in structure and application. Bast fibers, derived from the outer layer of the hemp stalk, are long, strong, and valued for textiles, ropes, and biocomposites. Hurds, the woody inner core, provide absorbency and insulation qualities, making them ideal for animal bedding, construction materials, and paper production.

What Are Bast Fibers?

Bast fibers are strong, fibrous materials extracted from the outer bark or phloem of the hemp stalk, offering durability and flexibility ideal for textiles, ropes, and composites. In contrast, hemp hurds, also known as woody core fibers, are the softer, inner parts of the stalk primarily used for animal bedding, paper production, and construction materials like hempcrete. Bast fibers contain cellulose, hemicellulose, and lignin, contributing to their tensile strength and making them a preferred choice in sustainable fabric and biocomposite manufacturing.

Understanding Hemp Hurds

Hemp hurds, the woody inner core of the hemp stalk, differ significantly from bast fibers, which are the outer long fibers used in textiles and rope production. Hurds are coarser, more absorbent, and ideal for applications such as animal bedding, biocomposites, and construction materials like hempcrete. Understanding the unique properties of hemp hurds enables optimized use in sustainable industries focused on eco-friendly alternatives to traditional wood and synthetic materials.

Key Differences Between Bast Fiber and Hurds

Bast fiber, derived from the outer bark of the hemp stalk, is long, strong, and flexible, making it ideal for textiles, ropes, and composite materials. In contrast, hurds are the inner woody core of the hemp stalk, characterized by short, coarse fibers primarily used in construction materials, animal bedding, and paper production. The key differences lie in their fiber length, strength, location on the stalk, and typical industrial applications.

Extraction Process: Bast Fiber vs Hurds

The extraction process for hemp bast fibers involves retting, where microbial activity or chemical treatment breaks down the pectin binding fibers to the stem's outer layer, facilitating fiber separation. In contrast, the extraction of hemp hurds requires mechanical decortication to crush and separate the woody core from the outer bast fibers, followed by cleaning to remove residual bast material. Bast fiber extraction focuses on preserving long, strong fibers for textiles, whereas hurd processing targets the short, woody inner core for uses like animal bedding and construction materials.

Physical Properties Comparison

Bast fibers, derived from the outer layer of the hemp stalk, exhibit high tensile strength, flexibility, and durability, making them ideal for textiles and ropes. Hurds, the woody inner core, possess lower tensile strength but offer superior absorbency and brittleness, commonly used in construction materials like hempcrete. The density of bast fibers is approximately 1.48 g/cm3, while hurds have a lower density around 1.25 g/cm3, influencing their respective mechanical performance and application suitability.

Common Uses of Bast Fibers

Bast fibers, derived from the outer layer of hemp stalks, are commonly used in textiles, ropes, and eco-friendly composite materials due to their strength and flexibility. Unlike hurds, which primarily serve as animal bedding or raw material for paper and construction, bast fibers provide high-quality fiber for sustainable clothing, industrial fabrics, and biodegradable composites. Their durability and natural resistance to pests make bast fibers essential in producing environmentally friendly products across the fashion and automotive industries.

Typical Applications of Hemp Hurds

Hemp hurds, the woody inner core of the hemp stalk, are primarily used in construction materials such as hempcrete for insulation and sustainable building. Their high absorbency and low density make them ideal for animal bedding and substrate in horticulture. Hemp hurds are also utilized in manufacturing paper and bio-composites, providing an eco-friendly alternative to traditional materials.

Sustainability and Environmental Impact

Bast fiber, derived from the outer part of the hemp stalk, offers superior tensile strength and durability, making it ideal for sustainable textiles and biocomposites. Hurds, the woody inner core, are highly absorbent and biodegradable, widely used in eco-friendly construction materials and animal bedding. Both bast fibers and hurds contribute to hemp's low environmental impact by requiring minimal pesticides, enhancing soil health, and supporting carbon sequestration.

Choosing the Right Hemp Material for Your Needs

Bast fibers, derived from the outer stalk of the hemp plant, offer exceptional tensile strength and flexibility, making them ideal for textiles, ropes, and composites. Hurds, the woody inner core, provide superior insulation, absorbency, and biodegradability, suited for construction materials, animal bedding, and biofuel production. Selecting between bast fibers and hurds depends on the specific application, balancing the demand for durability versus absorbency and structural support.

Bast fiber vs hurds Infographic

materialdif.com

materialdif.com