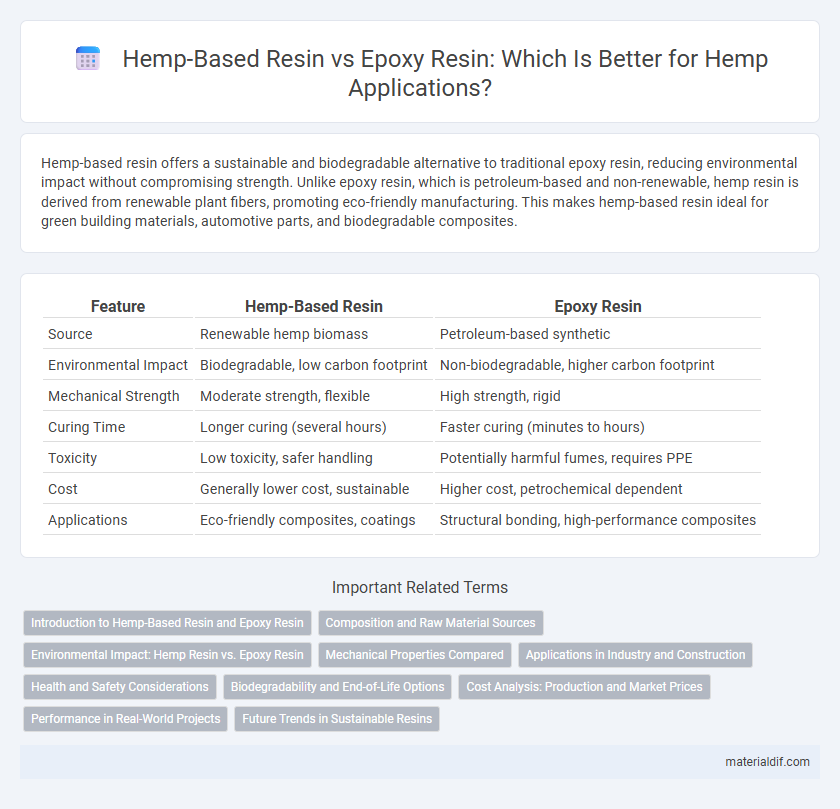

Hemp-based resin offers a sustainable and biodegradable alternative to traditional epoxy resin, reducing environmental impact without compromising strength. Unlike epoxy resin, which is petroleum-based and non-renewable, hemp resin is derived from renewable plant fibers, promoting eco-friendly manufacturing. This makes hemp-based resin ideal for green building materials, automotive parts, and biodegradable composites.

Table of Comparison

| Feature | Hemp-Based Resin | Epoxy Resin |

|---|---|---|

| Source | Renewable hemp biomass | Petroleum-based synthetic |

| Environmental Impact | Biodegradable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Mechanical Strength | Moderate strength, flexible | High strength, rigid |

| Curing Time | Longer curing (several hours) | Faster curing (minutes to hours) |

| Toxicity | Low toxicity, safer handling | Potentially harmful fumes, requires PPE |

| Cost | Generally lower cost, sustainable | Higher cost, petrochemical dependent |

| Applications | Eco-friendly composites, coatings | Structural bonding, high-performance composites |

Introduction to Hemp-Based Resin and Epoxy Resin

Hemp-based resin is a sustainable, bio-composite material derived from hemp fibers and natural polymers, offering eco-friendly alternatives to traditional petroleum-based resins. Epoxy resin, a synthetic polymer commonly used for strong adhesion and chemical resistance, is widely utilized in construction, automotive, and marine industries. Hemp-based resin provides comparable mechanical properties with lower environmental impact, making it an innovative substitution in resin applications.

Composition and Raw Material Sources

Hemp-based resin is derived from naturally renewable raw materials such as hemp fibers and oils, promoting sustainability and reduced environmental impact compared to traditional epoxy resin, which is primarily synthesized from petrochemical sources like bisphenol-A and epichlorohydrin. The composition of hemp resin incorporates bio-based polymers and lignin content, enhancing biodegradability and reducing toxicity. Epoxy resin features a synthetic polymer matrix designed for high mechanical strength and chemical resistance but relies heavily on non-renewable fossil fuels as its raw material source.

Environmental Impact: Hemp Resin vs. Epoxy Resin

Hemp-based resin offers a significantly lower environmental impact compared to traditional epoxy resin due to its renewable origin and biodegradability, reducing reliance on fossil fuels and minimizing long-term waste. Unlike epoxy resin, which often contains toxic chemicals and emits volatile organic compounds (VOCs) during curing, hemp resin produces fewer harmful emissions and poses less risk to ecosystems. The carbon sequestration properties of hemp plants further enhance the sustainability profile of hemp resins, making them a greener alternative in resin applications.

Mechanical Properties Compared

Hemp-based resin exhibits notable mechanical properties such as high tensile strength and flexibility, often outperforming traditional epoxy resin in impact resistance and environmental sustainability. While epoxy resin is known for its superior hardness and chemical resistance, hemp-based resin provides a lightweight alternative with enhanced biodegradability and comparable stiffness. The use of natural fibers in hemp resin composites contributes to improved fatigue resistance and reduced brittleness compared to conventional epoxy formulations.

Applications in Industry and Construction

Hemp-based resin offers a sustainable alternative to traditional epoxy resin in industry and construction, excelling in eco-friendly composite materials and structural components due to its biodegradability and lower carbon footprint. Its natural fibers enhance mechanical strength and flexibility in panels, coatings, and adhesives, making it ideal for green building projects and automotive manufacturing. Industrial applications benefit from hemp-based resin's resistance to UV radiation and chemicals, promoting durability while supporting circular economy principles.

Health and Safety Considerations

Hemp-based resin offers a safer alternative to epoxy resin by reducing exposure to toxic chemicals such as bisphenol-A (BPA) and volatile organic compounds (VOCs), which are common in traditional epoxy formulations. Its natural composition minimizes respiratory risks and skin irritations, making it more suitable for use in poorly ventilated spaces. Hemp resin's biodegradability also lessens environmental hazards, supporting sustainable and non-toxic manufacturing practices.

Biodegradability and End-of-Life Options

Hemp-based resin offers superior biodegradability compared to traditional epoxy resin, breaking down naturally in soil within months due to its organic composition. In contrast, epoxy resin is derived from synthetic chemicals, making it resistant to degradation and contributing to long-term environmental pollution. End-of-life options for hemp-based resin include composting and bio-recycling, whereas epoxy resin typically requires energy-intensive incineration or landfill disposal.

Cost Analysis: Production and Market Prices

Hemp-based resin offers a cost-effective alternative to traditional epoxy resin with lower raw material expenses due to the renewable and abundant nature of hemp fibers. Production costs for hemp resin are generally reduced by simplified extraction processes and lower energy requirements compared to petroleum-based epoxy resins. Market prices favor hemp-based resins as growing demand for sustainable materials drives competitive pricing, making them an increasingly attractive option for eco-conscious manufacturers.

Performance in Real-World Projects

Hemp-based resin exhibits superior biodegradability and lower environmental impact compared to traditional epoxy resin, making it increasingly favored in sustainable construction and automotive applications. While epoxy resin offers higher mechanical strength and chemical resistance, hemp-based resin delivers sufficient durability and flexibility for real-world projects that prioritize eco-friendly materials. Performance tests in structural composites reveal hemp resin's competitive load-bearing capacity and improved moisture resistance when modified with natural additives.

Future Trends in Sustainable Resins

Hemp-based resin is emerging as a promising sustainable alternative to traditional epoxy resin due to its biodegradability, lower carbon footprint, and renewable sourcing from industrial hemp fibers. Future trends indicate increased investment in hemp composite technologies, enhancing mechanical properties and curing processes to rival epoxy resins in construction and automotive applications. Regulatory incentives and growing consumer demand for eco-friendly materials accelerate the development and commercialization of hemp-based resins in the sustainable resin market.

hemp-based resin vs epoxy resin Infographic

materialdif.com

materialdif.com