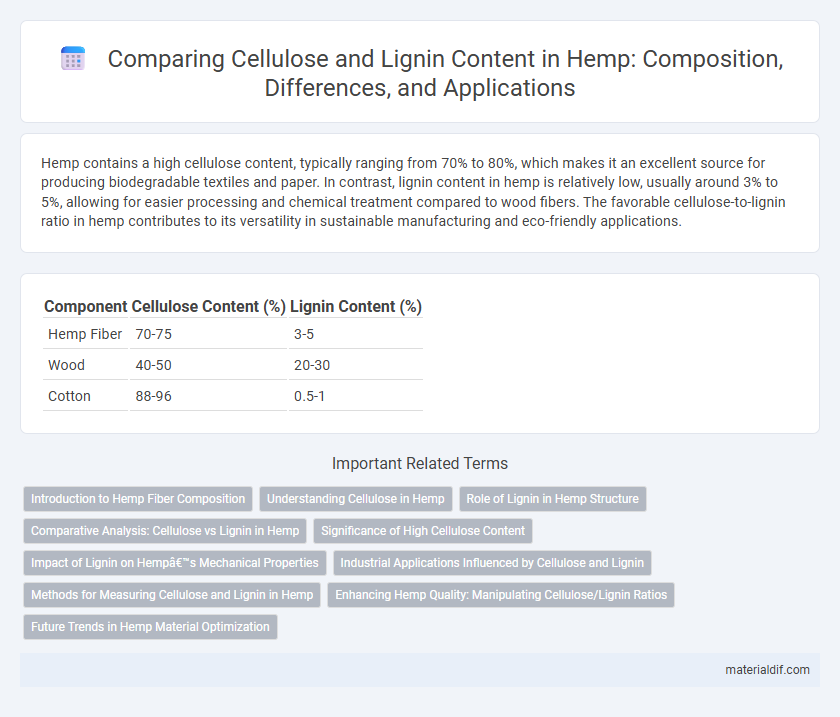

Hemp contains a high cellulose content, typically ranging from 70% to 80%, which makes it an excellent source for producing biodegradable textiles and paper. In contrast, lignin content in hemp is relatively low, usually around 3% to 5%, allowing for easier processing and chemical treatment compared to wood fibers. The favorable cellulose-to-lignin ratio in hemp contributes to its versatility in sustainable manufacturing and eco-friendly applications.

Table of Comparison

| Component | Cellulose Content (%) | Lignin Content (%) |

|---|---|---|

| Hemp Fiber | 70-75 | 3-5 |

| Wood | 40-50 | 20-30 |

| Cotton | 88-96 | 0.5-1 |

Introduction to Hemp Fiber Composition

Hemp fibers consist primarily of cellulose and lignin, with cellulose content typically ranging from 70% to 77%, providing strength and flexibility. Lignin content in hemp fibers is relatively low, usually between 3% and 5%, contributing to rigidity and resistance to microbial attack. This unique composition makes hemp fibers highly valuable for applications requiring durability and biodegradability.

Understanding Cellulose in Hemp

Cellulose in hemp accounts for approximately 70% of the fiber composition, providing significant strength and durability crucial for textile and biocomposite applications. Lignin content, typically around 3-5%, acts as a natural binder but reduces fiber flexibility and processability. Understanding the high cellulose-to-lignin ratio in hemp is essential for optimizing extraction methods and enhancing material performance in eco-friendly industrial uses.

Role of Lignin in Hemp Structure

Lignin in hemp provides critical rigidity and resistance to microbial attack, making it essential for the plant's structural integrity and durability. While cellulose is the main component contributing to tensile strength, lignin acts as a natural binder, reinforcing hemp fibers and enhancing their resilience. The balance between cellulose (up to 70%) and lignin (approximately 3-5%) defines the mechanical properties crucial for industrial applications like textiles and biocomposites.

Comparative Analysis: Cellulose vs Lignin in Hemp

Hemp fibers contain approximately 70-77% cellulose, which provides strength and stiffness, compared to 3-5% lignin responsible for rigidity and resistance to microbial attack. The high cellulose content makes hemp an ideal material for textiles and composites, while the lower lignin content enhances flexibility and ease of processing. Comparative analysis reveals that optimizing the cellulose-to-lignin ratio is crucial for improving hemp fiber applications in biodegradable products and sustainable construction materials.

Significance of High Cellulose Content

High cellulose content in hemp enhances its utility for producing biodegradable textiles, paper, and bio-composites due to its strength and flexibility. Compared to lignin, which provides rigidity but limits biodegradability and processing ease, cellulose offers superior fiber quality essential for industrial applications. The significant cellulose proportion, often exceeding 70% in hemp stalks, makes it a sustainable raw material for eco-friendly manufacturing.

Impact of Lignin on Hemp’s Mechanical Properties

Higher lignin content in hemp significantly enhances its mechanical strength and rigidity by providing structural support and resistance to compression. While cellulose primarily contributes to tensile strength and flexibility, lignin's complex polymer matrix improves durability and impact resistance, making hemp fibers suitable for composite materials and bioplastics. Optimal balance between cellulose and lignin dictates hemp's performance in industrial applications, influencing fiber processing and end-product quality.

Industrial Applications Influenced by Cellulose and Lignin

Hemp contains high cellulose levels, typically around 60-70%, which enhances its suitability for industrial applications such as paper production, textiles, and bio-composites due to cellulose's strength and flexibility. Lignin content in hemp, ranging from 3-10%, provides rigidity and resistance to microbial attack, making it valuable in construction materials and biofuel production. The balance of cellulose and lignin influences the processing methods and end-use efficiency across sectors like automotive manufacturing, packaging, and sustainable building materials.

Methods for Measuring Cellulose and Lignin in Hemp

Accurate quantification of cellulose and lignin in hemp is essential for optimizing fiber quality and industrial applications. Common methods for measuring cellulose include the Updegraff method and acid detergent fiber (ADF) analysis, which isolate cellulose by removing hemicellulose and lignin, while lignin content is typically assessed using the Klason lignin method or acid-insoluble residue analysis. Advanced techniques such as Fourier-transform infrared spectroscopy (FTIR) and thermogravimetric analysis (TGA) offer non-destructive, rapid profiling of cellulose and lignin ratios, enhancing precision in hemp biomass characterization.

Enhancing Hemp Quality: Manipulating Cellulose/Lignin Ratios

Enhancing hemp quality involves optimizing the cellulose-to-lignin ratio to improve fiber strength and flexibility. Higher cellulose content increases tensile strength and fiber purity, while controlled lignin levels contribute to durability without compromising biodegradability. Advanced breeding and biotechnological techniques enable precise manipulation of these ratios, resulting in superior hemp biomass for textiles, composites, and bio-based products.

Future Trends in Hemp Material Optimization

Hemp fibers with higher cellulose content and reduced lignin levels enhance strength, flexibility, and biodegradability, driving innovation in sustainable composites and textiles. Emerging breeding techniques and enzymatic treatments target optimizing cellulose-to-lignin ratios to improve processing efficiency and material performance. Future trends emphasize green chemistry and bioengineering to customize hemp fiber properties for advanced industrial applications.

Cellulose content vs Lignin content Infographic

materialdif.com

materialdif.com