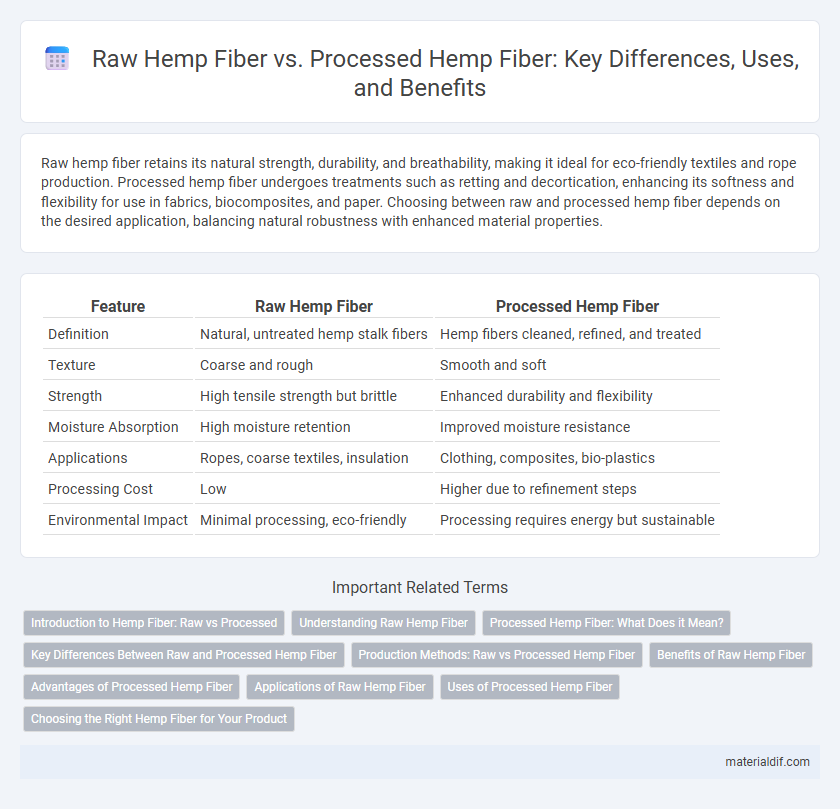

Raw hemp fiber retains its natural strength, durability, and breathability, making it ideal for eco-friendly textiles and rope production. Processed hemp fiber undergoes treatments such as retting and decortication, enhancing its softness and flexibility for use in fabrics, biocomposites, and paper. Choosing between raw and processed hemp fiber depends on the desired application, balancing natural robustness with enhanced material properties.

Table of Comparison

| Feature | Raw Hemp Fiber | Processed Hemp Fiber |

|---|---|---|

| Definition | Natural, untreated hemp stalk fibers | Hemp fibers cleaned, refined, and treated |

| Texture | Coarse and rough | Smooth and soft |

| Strength | High tensile strength but brittle | Enhanced durability and flexibility |

| Moisture Absorption | High moisture retention | Improved moisture resistance |

| Applications | Ropes, coarse textiles, insulation | Clothing, composites, bio-plastics |

| Processing Cost | Low | Higher due to refinement steps |

| Environmental Impact | Minimal processing, eco-friendly | Processing requires energy but sustainable |

Introduction to Hemp Fiber: Raw vs Processed

Raw hemp fiber retains its natural outer bark called the hurd, offering coarse texture and high durability suitable for industrial applications such as rope and mats. Processed hemp fiber undergoes retting and decortication to separate the softer bast fibers, resulting in finer, more flexible material ideal for textiles and composites. The differences in fiber structure and treatment influence the end-use properties, making raw hemp more rigid and processed hemp more versatile for diverse industries.

Understanding Raw Hemp Fiber

Raw hemp fiber, derived directly from the stalk after retting and decortication, retains its natural lignin and impurities, resulting in a coarse texture and higher durability. It offers superior strength and breathability ideal for heavy-duty textiles, ropes, and construction materials compared to processed hemp fiber, which is softer and cleaner due to additional treatments like carding and combing. Understanding the characteristics of raw hemp fiber is crucial for optimizing its use in industrial applications that prioritize natural resilience and environmental sustainability.

Processed Hemp Fiber: What Does it Mean?

Processed hemp fiber refers to raw hemp stalks that have undergone treatments such as decortication, retting, and scutching to remove non-fibrous materials, resulting in cleaner, softer, and more durable fibers suitable for textiles and composites. This refinement enhances fiber quality by increasing tensile strength and flexibility, making processed hemp fiber ideal for applications in fabric production, paper manufacturing, and bioplastics. Unlike raw hemp fiber, processed hemp fiber exhibits higher consistency and purity, which significantly improves its performance in industrial and commercial products.

Key Differences Between Raw and Processed Hemp Fiber

Raw hemp fiber retains its natural lignin, pectin, and waxes, resulting in a coarser texture and higher moisture content compared to processed hemp fiber. Processed hemp fiber undergoes retting, decortication, and carding to remove impurities, enhance softness, and improve tensile strength, making it more suitable for textiles and composites. The key differences lie in the fiber's cleanliness, durability, and application potential, with processed hemp fiber offering superior performance for industrial uses.

Production Methods: Raw vs Processed Hemp Fiber

Raw hemp fiber is obtained directly from the initial retting and decortication processes, retaining its natural lignin and cellulose content which contributes to its coarse texture and limited flexibility. Processed hemp fiber undergoes further treatments such as combing, carding, and sometimes chemical retting to remove impurities and lignin, resulting in finer, softer fibers suitable for textiles and high-value applications. Production methods for processed hemp fiber require additional mechanical or chemical steps to enhance fiber quality, improving durability and compatibility with various manufacturing processes.

Benefits of Raw Hemp Fiber

Raw hemp fiber retains its natural lignin and cellulose content, providing superior strength and durability compared to processed hemp fiber. This unrefined fiber offers enhanced breathability and moisture-wicking properties, making it ideal for eco-friendly textiles and sustainable construction materials. The minimal processing preserves the fiber's biodegradability and reduces environmental impact, supporting zero-waste manufacturing practices.

Advantages of Processed Hemp Fiber

Processed hemp fiber offers superior durability and uniformity compared to raw hemp fiber, making it ideal for high-quality textile production. Enhanced removal of lignin and impurities during processing enhances the fiber's flexibility and softness, boosting comfort in end-use applications. This refined fiber also exhibits improved dye retention and resistance to microbial growth, extending the lifespan of hemp-based products.

Applications of Raw Hemp Fiber

Raw hemp fiber retains its natural strength and coarse texture, making it ideal for applications such as rope, canvas, and insulation materials where durability and breathability are essential. Its high lignin content provides stiffness and resistance to microbial degradation, which benefits products requiring structural integrity and longevity. Unlike processed hemp fiber, raw hemp fiber is less refined and better suited for heavy-duty industrial uses, including automotive composites and geotextiles.

Uses of Processed Hemp Fiber

Processed hemp fiber undergoes treatments such as retting, decortication, and refining to enhance its strength, flexibility, and texture, making it ideal for textile production, composite materials, and eco-friendly packaging. Its refined quality allows for use in high-performance fabrics, biodegradable plastics, and insulation materials in construction. Processed hemp fiber's versatility supports sustainable industries by providing durable, renewable alternatives to conventional synthetic fibers and materials.

Choosing the Right Hemp Fiber for Your Product

Raw hemp fiber retains more lignin and natural waxes, providing increased durability and water resistance ideal for outdoor textiles and heavy-duty applications. Processed hemp fiber undergoes retting and decortication, resulting in softer, finer fibers suited for apparel, upholstery, and eco-friendly composites. Selecting the right hemp fiber depends on product requirements for strength, texture, and environmental sustainability.

Raw Hemp Fiber vs Processed Hemp Fiber Infographic

materialdif.com

materialdif.com