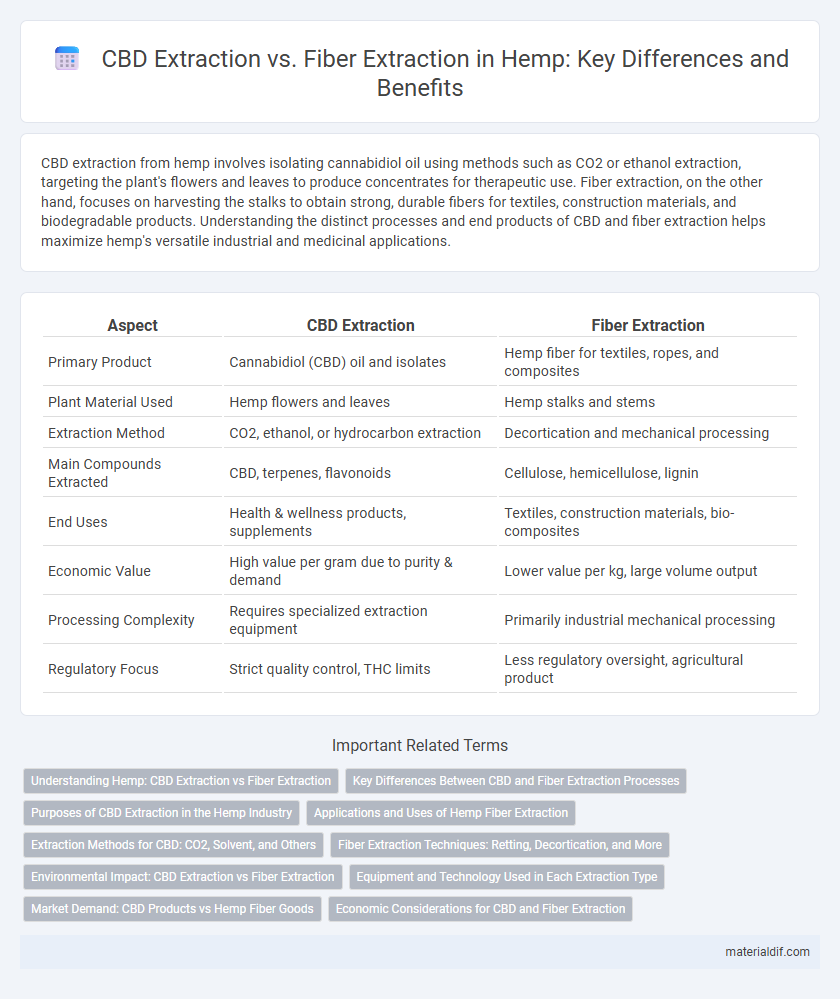

CBD extraction from hemp involves isolating cannabidiol oil using methods such as CO2 or ethanol extraction, targeting the plant's flowers and leaves to produce concentrates for therapeutic use. Fiber extraction, on the other hand, focuses on harvesting the stalks to obtain strong, durable fibers for textiles, construction materials, and biodegradable products. Understanding the distinct processes and end products of CBD and fiber extraction helps maximize hemp's versatile industrial and medicinal applications.

Table of Comparison

| Aspect | CBD Extraction | Fiber Extraction |

|---|---|---|

| Primary Product | Cannabidiol (CBD) oil and isolates | Hemp fiber for textiles, ropes, and composites |

| Plant Material Used | Hemp flowers and leaves | Hemp stalks and stems |

| Extraction Method | CO2, ethanol, or hydrocarbon extraction | Decortication and mechanical processing |

| Main Compounds Extracted | CBD, terpenes, flavonoids | Cellulose, hemicellulose, lignin |

| End Uses | Health & wellness products, supplements | Textiles, construction materials, bio-composites |

| Economic Value | High value per gram due to purity & demand | Lower value per kg, large volume output |

| Processing Complexity | Requires specialized extraction equipment | Primarily industrial mechanical processing |

| Regulatory Focus | Strict quality control, THC limits | Less regulatory oversight, agricultural product |

Understanding Hemp: CBD Extraction vs Fiber Extraction

CBD extraction from hemp targets the plant's glandular trichomes, yielding concentrated cannabidiol used for therapeutic products, while fiber extraction focuses on the stalks, producing durable materials for textiles, construction, and bioplastics. The extraction processes differ significantly, with CBD extraction often involving solvents or CO2 to isolate cannabinoids, whereas fiber extraction uses mechanical retting and decortication to separate cellulose fibers. Understanding these distinctions is essential for optimizing hemp cultivation and industrial applications based on specific end-product requirements.

Key Differences Between CBD and Fiber Extraction Processes

CBD extraction from hemp primarily targets the plant's trichomes using methods like CO2 or ethanol extraction to isolate cannabinoids and terpenes, yielding concentrated oils or isolates. Fiber extraction, however, involves mechanical processes such as decortication and retting that separate the bast fibers from the stalk, producing coarse materials for textiles, composites, or construction. The key differences lie in the targeted plant components and extraction techniques--chemical-solvent-based for CBD and physical-mechanical for fiber--reflecting distinct end-product purposes and industry applications.

Purposes of CBD Extraction in the Hemp Industry

CBD extraction in the hemp industry primarily targets the isolation of cannabidiol for therapeutic and wellness applications, capitalizing on its anti-inflammatory, anxiolytic, and neuroprotective properties. Unlike fiber extraction, which focuses on obtaining hemp stalks for textiles, paper, and construction materials, CBD extraction involves advanced techniques such as CO2 and ethanol extraction to achieve high-purity cannabinoid concentrates. The resulting CBD products, including tinctures, topicals, and edibles, drive significant consumer demand in health, pharmaceutical, and cosmetic markets.

Applications and Uses of Hemp Fiber Extraction

Hemp fiber extraction yields strong, durable fibers primarily used in textiles, construction materials, and biodegradable composites, offering sustainable alternatives to traditional fibers. These fibers are integral in producing eco-friendly clothing, ropes, paper, and insulation panels due to their natural strength and resistance to pests. Unlike CBD extraction, which targets medicinal and wellness products, hemp fiber extraction focuses on industrial applications that contribute to green manufacturing and circular economy initiatives.

Extraction Methods for CBD: CO2, Solvent, and Others

CO2 extraction for CBD is favored for its efficiency and purity, using pressurized carbon dioxide to isolate cannabinoids without residual solvents. Solvent extraction employs alcohol or hydrocarbons to dissolve CBD, offering faster processing but requiring careful purification to remove toxic residues. Alternative methods such as lipid infusion and steam distillation provide natural extraction options, with varying yields and purity levels depending on processing parameters.

Fiber Extraction Techniques: Retting, Decortication, and More

Fiber extraction from hemp primarily involves retting, a process where microbial activity breaks down pectins to separate bast fibers, followed by decortication, which mechanically strips the fiber from the stalk. Retting methods include water retting, dew retting, and enzymatic retting, each influencing fiber quality, while decortication uses rollers or crushers for efficient fiber separation. These techniques optimize fiber yield and strength, essential for industrial applications like textiles, composites, and bioplastics.

Environmental Impact: CBD Extraction vs Fiber Extraction

CBD extraction from hemp typically involves solvents or CO2 methods that consume more energy and generate chemical waste, increasing environmental strain. In contrast, fiber extraction is mechanically driven, producing minimal waste and requiring less energy, making it a more sustainable option. Evaluating the carbon footprint and resource use highlights fiber processing as having a considerably lower environmental impact compared to CBD extraction.

Equipment and Technology Used in Each Extraction Type

CBD extraction from hemp primarily utilizes advanced equipment such as supercritical CO2 extractors, ethanol-based systems, and hydrocarbon extraction machines designed to isolate cannabinoids with high purity. Fiber extraction involves mechanical processing technology including decorticators, fiber decortication machines, and retting systems that separate bast fibers from the stalk while preserving fiber integrity. Innovations in these extraction technologies enhance efficiency, product quality, and scalability within the hemp industry.

Market Demand: CBD Products vs Hemp Fiber Goods

Market demand for CBD products has surged dramatically due to increasing consumer interest in health and wellness applications, driving rapid growth in the CBD extraction industry. In contrast, hemp fiber goods cater to established markets in textiles, construction, and biodegradable materials, experiencing steady but slower expansion. The economic potential of CBD extraction currently outpaces fiber extraction, fueled by high-value cannabinoid concentrates and diverse product formulations.

Economic Considerations for CBD and Fiber Extraction

CBD extraction from hemp typically demands higher investment due to the advanced technology and purification processes required, leading to greater production costs but higher market value per gram. Fiber extraction emphasizes large-scale mechanical processing, which offers economies of scale and lower per-unit costs but yields products with lower profit margins compared to CBD oils and concentrates. Market demand fluctuations and regulatory factors also significantly impact the economic viability of both extraction methods, influencing farmers' and processors' profitability strategies.

CBD extraction vs fiber extraction Infographic

materialdif.com

materialdif.com