Hempcrete curing differs significantly from traditional concrete curing, as hempcrete requires a slower, moisture-controlled process to achieve optimal strength and insulation properties. Unlike concrete, which hardens through a chemical hydration reaction within days, hempcrete cures by drying and carbonation over several weeks, ensuring breathability and flexibility in construction. Proper curing of hempcrete enhances its thermal performance and durability, making it a sustainable alternative to conventional concrete.

Table of Comparison

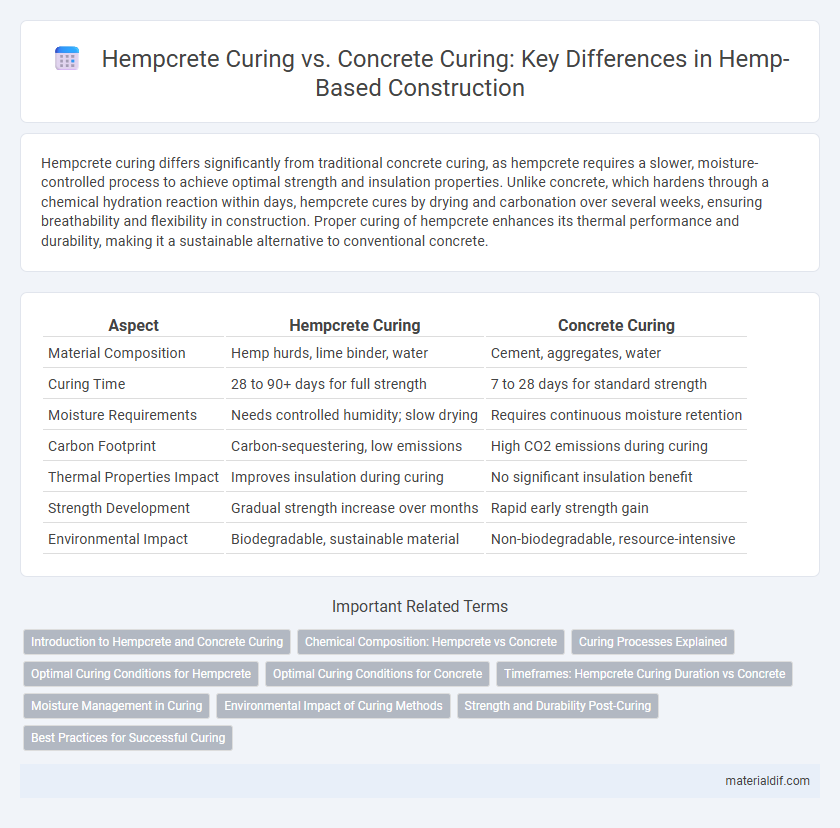

| Aspect | Hempcrete Curing | Concrete Curing |

|---|---|---|

| Material Composition | Hemp hurds, lime binder, water | Cement, aggregates, water |

| Curing Time | 28 to 90+ days for full strength | 7 to 28 days for standard strength |

| Moisture Requirements | Needs controlled humidity; slow drying | Requires continuous moisture retention |

| Carbon Footprint | Carbon-sequestering, low emissions | High CO2 emissions during curing |

| Thermal Properties Impact | Improves insulation during curing | No significant insulation benefit |

| Strength Development | Gradual strength increase over months | Rapid early strength gain |

| Environmental Impact | Biodegradable, sustainable material | Non-biodegradable, resource-intensive |

Introduction to Hempcrete and Concrete Curing

Hempcrete, a bio-composite material made from hemp hurds and lime-based binder, cures through a carbonation process that involves absorption of CO2, resulting in gradual hardening over weeks to months. In contrast, conventional concrete cures by hydration, where cement reacts with water to form a rigid matrix typically gaining most strength within 28 days. The curing of hempcrete emphasizes breathability and moisture regulation, making it an eco-friendly alternative with lower carbon footprint compared to traditional concrete curing methods.

Chemical Composition: Hempcrete vs Concrete

Hempcrete curing differs significantly from concrete curing due to its unique chemical composition, primarily composed of hemp hurd, lime binder, and water, which undergoes carbonation rather than hydration. Unlike concrete, where calcium silicates react with water to form calcium silicate hydrate (C-S-H) that provides strength, hempcrete relies on the slow absorption of carbon dioxide, transforming calcium hydroxide into calcium carbonate for solidification. This natural carbonation process results in a lightweight, breathable, and sustainable material with distinct thermal and environmental advantages compared to traditional concrete curing.

Curing Processes Explained

Hempcrete curing relies on a carbonation process where carbon dioxide reacts with lime to harden the material, contrasting with concrete curing, which involves hydration and the chemical reaction of cement with water. Hempcrete requires slower curing times, often several weeks to months, to achieve optimal strength and durability while maintaining breathability and thermal insulation. Concrete typically cures within 28 days, reaching maximum compressive strength, but lacks the natural insulating and moisture-regulating properties of hempcrete.

Optimal Curing Conditions for Hempcrete

Optimal curing conditions for hempcrete prioritize maintaining moisture levels between 50-70% relative humidity and temperatures ranging from 15-25degC to ensure proper carbonation and strength development. Unlike concrete, which requires continuous moisture for hydration, hempcrete cures through carbonation, necessitating a balance of moisture and airflow to prevent drying out or excessive dampness. Proper curing of hempcrete enhances its insulating properties and durability, making controlled environmental conditions essential during the initial 28-day curing period.

Optimal Curing Conditions for Concrete

Optimal curing conditions for concrete require maintaining a consistent temperature between 50degF and 85degF (10degC to 29degC) and keeping the surface moist to ensure proper hydration of cement particles. Concrete typically benefits from a curing period of at least 7 days to achieve desired strength, with adequate humidity levels above 70% to prevent premature drying and cracking. This contrasts with hempcrete, which cures through carbonation and requires longer times and ambient airflow rather than moisture retention.

Timeframes: Hempcrete Curing Duration vs Concrete

Hempcrete curing typically spans 2 to 4 weeks, allowing the material to dry and gain strength gradually while maintaining breathability. In contrast, traditional concrete reaches initial curing within 7 days but requires up to 28 days to achieve full strength and durability. Hempcrete's extended curing duration is essential for optimal moisture regulation and thermal performance in sustainable construction.

Moisture Management in Curing

Hempcrete curing relies on gradual moisture evaporation and carbonation, allowing lime-based binders to absorb atmospheric CO2 and solidify while maintaining internal humidity levels longer than traditional concrete. Concrete curing requires consistent moisture retention to prevent premature drying, which can cause cracking and reduce structural strength, typically achieved through continuous wetting or sealing methods. Effective moisture management in hempcrete results in improved breathability and thermal insulation, contrasting with concrete's dense, impermeable matrix that limits vapor permeability during the curing process.

Environmental Impact of Curing Methods

Hempcrete curing relies on carbonation, absorbing CO2 as it hardens, which significantly reduces its overall carbon footprint compared to traditional concrete curing that emits considerable CO2 through cement hydration. Unlike concrete, which requires energy-intensive heat curing or prolonged water curing, hempcrete cures at ambient temperatures, minimizing energy consumption and greenhouse gas emissions. These distinct curing methods position hempcrete as an environmentally sustainable alternative, contributing to carbon sequestration and lowering the environmental impact of construction materials.

Strength and Durability Post-Curing

Hempcrete exhibits lower compressive strength than traditional concrete but gains durability through continued carbonation during its extended curing process, enhancing its long-term structural integrity. Unlike concrete, which typically reaches maximum strength within 28 days, hempcrete's curing extends over months, increasing resistance to cracking and moisture damage. This gradual curing results in a lightweight, breathable material, ideal for sustainable construction with improved thermal and moisture regulation qualities.

Best Practices for Successful Curing

Hempcrete requires a slower, moisture-controlled curing process compared to traditional concrete to prevent cracking and ensure durability. Maintaining humidity levels around 50-70% and allowing hempcrete to dry gradually over several weeks promotes optimal carbonation and strength development. Unlike concrete, which relies on rapid hydration, hempcrete benefits from a curing environment that balances air circulation and moisture retention for successful structural performance.

Hempcrete curing vs Concrete curing Infographic

materialdif.com

materialdif.com