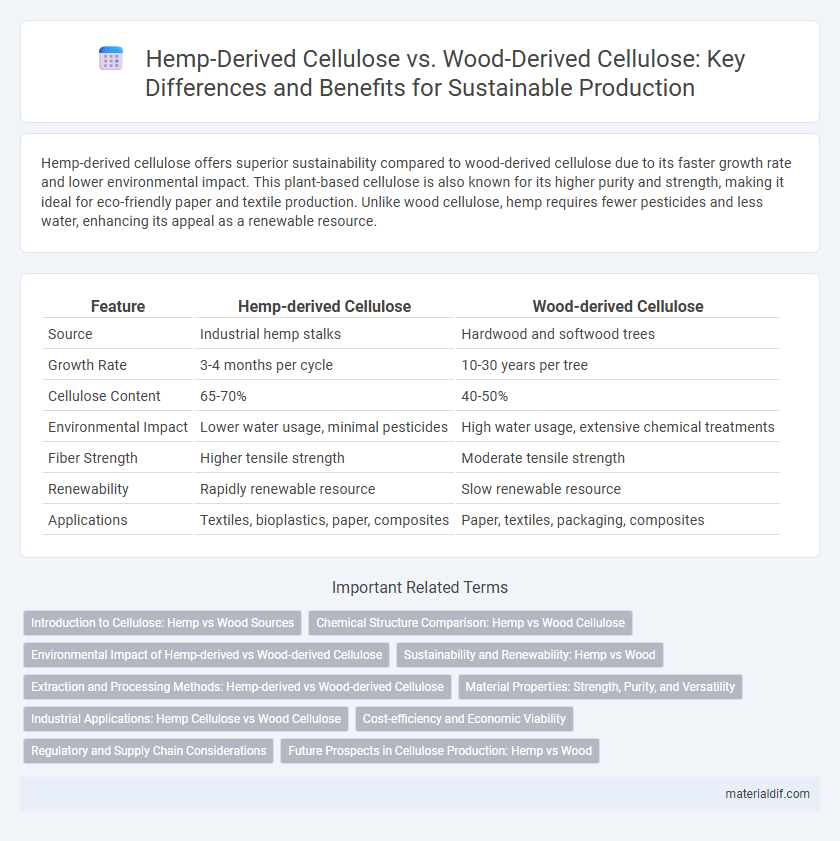

Hemp-derived cellulose offers superior sustainability compared to wood-derived cellulose due to its faster growth rate and lower environmental impact. This plant-based cellulose is also known for its higher purity and strength, making it ideal for eco-friendly paper and textile production. Unlike wood cellulose, hemp requires fewer pesticides and less water, enhancing its appeal as a renewable resource.

Table of Comparison

| Feature | Hemp-derived Cellulose | Wood-derived Cellulose |

|---|---|---|

| Source | Industrial hemp stalks | Hardwood and softwood trees |

| Growth Rate | 3-4 months per cycle | 10-30 years per tree |

| Cellulose Content | 65-70% | 40-50% |

| Environmental Impact | Lower water usage, minimal pesticides | High water usage, extensive chemical treatments |

| Fiber Strength | Higher tensile strength | Moderate tensile strength |

| Renewability | Rapidly renewable resource | Slow renewable resource |

| Applications | Textiles, bioplastics, paper, composites | Paper, textiles, packaging, composites |

Introduction to Cellulose: Hemp vs Wood Sources

Hemp-derived cellulose offers a higher purity and longer fiber length compared to wood-derived cellulose, making it ideal for producing durable textiles and sustainable paper products. Unlike wood cellulose obtained through energy-intensive chemical processes, hemp cellulose extraction requires fewer chemicals, resulting in a lower environmental impact. The unique molecular structure of hemp cellulose enhances its strength and biodegradability, positioning it as a superior alternative for eco-friendly materials.

Chemical Structure Comparison: Hemp vs Wood Cellulose

Hemp-derived cellulose exhibits a higher degree of polymerization and crystallinity compared to wood-derived cellulose, leading to enhanced mechanical strength and thermal stability. Its chemical structure contains fewer lignin impurities and a lower hemicellulose content, which improves purity and ease of processing. The unique arrangement of b-(1-4)-linked D-glucose units in hemp cellulose fibers results in superior fiber length and tensile properties relative to wood cellulose.

Environmental Impact of Hemp-derived vs Wood-derived Cellulose

Hemp-derived cellulose significantly reduces environmental impact compared to wood-derived cellulose due to its faster growth rate, requiring fewer pesticides and less water. The sustainable cultivation of hemp contributes to lower deforestation rates and a smaller carbon footprint, as hemp absorbs more CO2 per hectare than most trees. Additionally, hemp's minimal processing needs decrease energy consumption and chemical use, enhancing its eco-friendly profile relative to conventional wood pulp.

Sustainability and Renewability: Hemp vs Wood

Hemp-derived cellulose offers superior sustainability and renewability compared to wood-derived cellulose due to its faster growth cycle, requiring only 3-4 months to mature versus decades for trees. Hemp cultivation demands fewer pesticides and less water, reducing environmental impact and soil degradation. The efficient biomass yield per acre of hemp supports renewable material production while promoting carbon sequestration and biodiversity.

Extraction and Processing Methods: Hemp-derived vs Wood-derived Cellulose

Hemp-derived cellulose is extracted through a relatively low-impact retting process that utilizes microbial or enzyme treatments to separate fibers, preserving cellulose quality with fewer chemical inputs. Wood-derived cellulose typically undergoes energy-intensive pulping methods such as kraft or sulfite processes that involve harsh chemicals to break down lignin and hemicellulose, often reducing fiber integrity. The more sustainable and efficient extraction of hemp cellulose results in a higher purity and strength, making it favorable for textile and biodegradable material applications.

Material Properties: Strength, Purity, and Versatility

Hemp-derived cellulose exhibits superior tensile strength and higher purity compared to wood-derived cellulose, making it an ideal choice for durable and high-performance materials. The fine fiber structure of hemp cellulose enhances its versatility, enabling applications ranging from textiles to bioplastics with improved biodegradability. Unlike wood cellulose, hemp cellulose contains fewer lignin impurities, which facilitates easier processing and yields a more consistent, high-quality end product.

Industrial Applications: Hemp Cellulose vs Wood Cellulose

Hemp-derived cellulose offers superior tensile strength and enhanced biodegradability compared to wood-derived cellulose, making it ideal for sustainable packaging, textiles, and composite materials in industrial applications. Industrial usage of hemp cellulose leverages its rapid growth rate and lower environmental impact, reducing deforestation and carbon footprint in large-scale cellulose production. Wood cellulose maintains dominance in pulp and paper industries due to established supply chains, though hemp cellulose's ecological benefits and mechanical properties drive increasing adoption in innovative manufacturing sectors.

Cost-efficiency and Economic Viability

Hemp-derived cellulose offers greater cost-efficiency compared to wood-derived cellulose due to its faster growth cycle and higher yield per acre, reducing raw material expenses. The economic viability of hemp cellulose is amplified by lower processing costs and less energy-intensive pulping methods, leading to decreased overall production costs. Market trends indicate increasing demand for sustainable alternatives, positioning hemp cellulose as a competitive and profitable option in the cellulose industry.

Regulatory and Supply Chain Considerations

Hemp-derived cellulose benefits from fewer regulatory restrictions compared to wood-derived cellulose, as hemp cultivation is increasingly supported by sustainable agriculture policies worldwide. Supply chain considerations favor hemp due to its rapid growth cycle and lower environmental impact, enabling more predictable and shorter sourcing timelines than traditional forestry. Regulatory frameworks are evolving to streamline hemp processing approvals, positioning hemp cellulose as a more resilient and scalable alternative in the supply chain.

Future Prospects in Cellulose Production: Hemp vs Wood

Hemp-derived cellulose offers a more sustainable and faster-renewing alternative compared to traditional wood-derived cellulose, with hemp plants maturing in 3-4 months versus decades for trees. The higher cellulose content in hemp stalks, typically around 70-75%, enhances its efficiency for industrial applications such as textiles, paper, and bioplastics. Future prospects highlight hemp's potential to reduce deforestation, lower carbon emissions, and support circular bioeconomies through scalable and eco-friendly cellulose production.

Hemp-derived Cellulose vs Wood-derived Cellulose Infographic

materialdif.com

materialdif.com