Hemp-based rayon offers superior environmental benefits compared to viscose rayon due to hemp's rapid growth and minimal pesticide requirements, making it a more sustainable fiber source. The natural durability and breathability of hemp contribute to enhanced comfort and longevity in pet products. Hemp-based rayon also provides better moisture-wicking properties than viscose rayon, ensuring pets stay dry and comfortable during use.

Table of Comparison

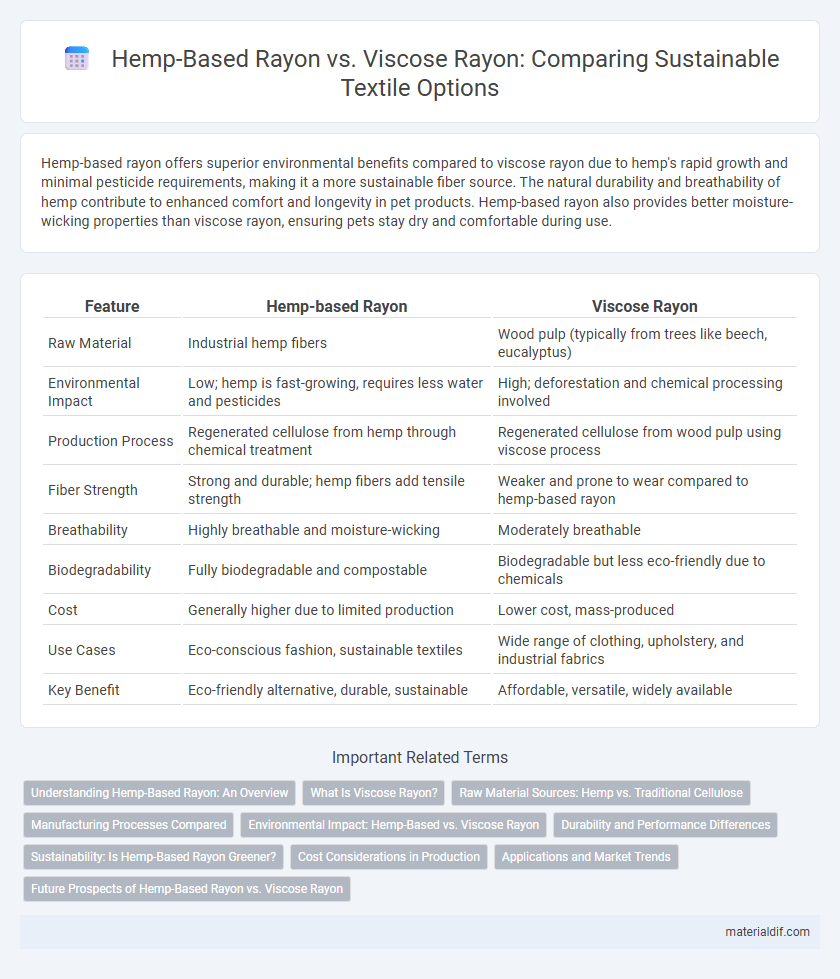

| Feature | Hemp-based Rayon | Viscose Rayon |

|---|---|---|

| Raw Material | Industrial hemp fibers | Wood pulp (typically from trees like beech, eucalyptus) |

| Environmental Impact | Low; hemp is fast-growing, requires less water and pesticides | High; deforestation and chemical processing involved |

| Production Process | Regenerated cellulose from hemp through chemical treatment | Regenerated cellulose from wood pulp using viscose process |

| Fiber Strength | Strong and durable; hemp fibers add tensile strength | Weaker and prone to wear compared to hemp-based rayon |

| Breathability | Highly breathable and moisture-wicking | Moderately breathable |

| Biodegradability | Fully biodegradable and compostable | Biodegradable but less eco-friendly due to chemicals |

| Cost | Generally higher due to limited production | Lower cost, mass-produced |

| Use Cases | Eco-conscious fashion, sustainable textiles | Wide range of clothing, upholstery, and industrial fabrics |

| Key Benefit | Eco-friendly alternative, durable, sustainable | Affordable, versatile, widely available |

Understanding Hemp-Based Rayon: An Overview

Hemp-based rayon is a sustainable fiber derived from hemp cellulose, offering enhanced environmental benefits compared to conventional viscose rayon produced from wood pulp. It exhibits superior strength, breathability, and biodegradability while requiring fewer chemicals and less water in its manufacturing process. This eco-friendly alternative supports reduced deforestation and promotes better soil health through hemp cultivation.

What Is Viscose Rayon?

Viscose rayon is a semi-synthetic fiber derived from cellulose, primarily obtained from wood pulp, and is widely used in textiles for its silk-like feel. Hemp-based rayon offers an eco-friendlier alternative by utilizing hemp fibers, which require less water and fewer chemicals during processing compared to traditional viscose made from hardwood trees. Both materials fall under the rayon category, but hemp-based rayon stands out for its sustainable sourcing and potential to reduce environmental impact in fabric production.

Raw Material Sources: Hemp vs. Traditional Cellulose

Hemp-based rayon utilizes fibers derived directly from the hemp plant, offering a sustainable and renewable raw material source with lower pesticide and water requirements compared to traditional cellulose sources. Traditional viscose rayon primarily relies on wood pulp from trees like beech, pine, or eucalyptus, which involves deforestation and intensive chemical processing. Hemp's rapid growth and greater biomass yield per acre make it a more environmentally friendly alternative for rayon production, reducing the environmental footprint associated with raw material sourcing.

Manufacturing Processes Compared

Hemp-based rayon manufacturing utilizes the cellulose fibers derived from hemp stalks, involving a chemical process that breaks down hemp cellulose into a viscous solution before regenerating it into fibers, often through the lyocell or viscose process. Viscose rayon primarily uses wood pulp as its cellulose source, undergoing similar chemical treatments but typically results in higher chemical waste and environmental impact during production. The distinct raw materials and processing methods make hemp-based rayon a more sustainable and biodegradable alternative with a lower carbon footprint in textile manufacturing.

Environmental Impact: Hemp-Based vs. Viscose Rayon

Hemp-based rayon significantly reduces environmental impact by utilizing hemp, a fast-growing, low-water crop with natural pest resistance, which lowers chemical inputs and soil degradation compared to viscose rayon. Viscose rayon production involves intensive chemical treatments and large water consumption, contributing to deforestation and pollution from industrial waste. Choosing hemp-based rayon supports sustainable fiber production with a smaller carbon footprint and improved biodegradability relative to traditional viscose.

Durability and Performance Differences

Hemp-based rayon offers superior durability compared to viscose rayon due to its higher cellulose content and stronger fiber structure, resulting in longer-lasting fabric performance. The natural resistance of hemp fibers to wear and tear enhances tensile strength and reduces pilling, making it ideal for heavy-use applications. Viscose rayon, derived from wood pulp, tends to have lower abrasion resistance and durability, which impacts its longevity and suitability for high-stress textile products.

Sustainability: Is Hemp-Based Rayon Greener?

Hemp-based rayon offers a significantly greener alternative to viscose rayon due to hemp's rapid growth cycle and lower pesticide requirements, reducing environmental impact and promoting biodiversity. The production of hemp fiber consumes less water and energy compared to viscose sourced from wood pulp, which often involves deforestation and chemical-intensive processing. Sustainable hemp cultivation contributes to soil regeneration and carbon sequestration, enhancing its appeal as an eco-friendly raw material in textile manufacturing.

Cost Considerations in Production

Hemp-based rayon production typically incurs higher initial costs due to the more sustainable and less chemically intensive processing methods compared to viscose rayon, which relies on extensive chemical treatments from wood pulp. Viscose rayon benefits from large-scale, established manufacturing infrastructure, resulting in lower production expenses and more competitive pricing. However, the growing demand for eco-friendly textiles is gradually reducing hemp-based rayon costs through technological advancements and increased cultivation efficiency.

Applications and Market Trends

Hemp-based rayon offers superior sustainability and durability compared to viscose rayon, making it increasingly favored in eco-conscious fashion and upholstery applications. Market trends reveal a growing demand for hemp fibers in textiles due to their biodegradability and lower environmental impact, driving innovation in hemp rayon manufacturing processes. This shift supports expansion in eco-friendly product lines across apparel, home furnishings, and automotive interiors sectors.

Future Prospects of Hemp-Based Rayon vs. Viscose Rayon

Hemp-based rayon offers a more sustainable future compared to viscose rayon due to its lower environmental impact, faster growth cycle, and reduced chemical usage during production. Innovations in refining hemp fibers for rayon improve softness and durability, positioning hemp as a competitive alternative in the textile industry. Projected market trends indicate increasing demand for eco-friendly materials, which is driving growth potential and investment in hemp-based rayon technologies.

Hemp-based rayon vs Viscose rayon Infographic

materialdif.com

materialdif.com