Nonwoven hemp textiles offer enhanced breathability and flexibility compared to woven hemp textiles, making them ideal for applications requiring lightweight and comfortable materials. Woven hemp textiles provide superior durability and strength due to their interlaced fiber structure, suitable for heavy-duty uses like upholstery and industrial fabrics. Choosing between nonwoven and woven hemp textiles depends on the desired balance between comfort and resilience in the final product.

Table of Comparison

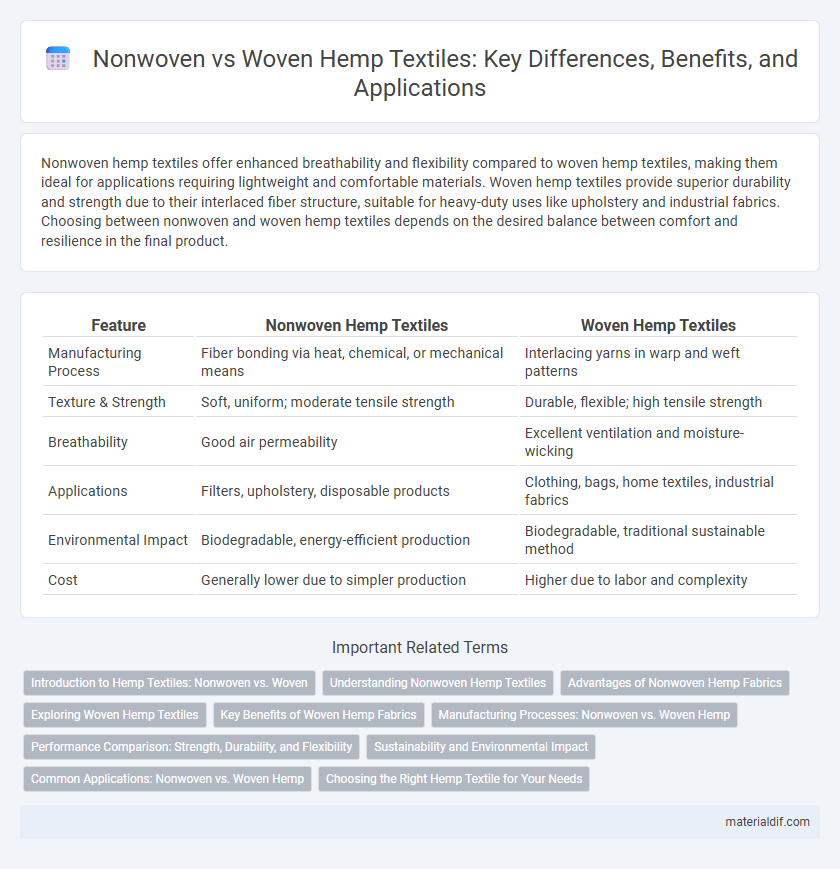

| Feature | Nonwoven Hemp Textiles | Woven Hemp Textiles |

|---|---|---|

| Manufacturing Process | Fiber bonding via heat, chemical, or mechanical means | Interlacing yarns in warp and weft patterns |

| Texture & Strength | Soft, uniform; moderate tensile strength | Durable, flexible; high tensile strength |

| Breathability | Good air permeability | Excellent ventilation and moisture-wicking |

| Applications | Filters, upholstery, disposable products | Clothing, bags, home textiles, industrial fabrics |

| Environmental Impact | Biodegradable, energy-efficient production | Biodegradable, traditional sustainable method |

| Cost | Generally lower due to simpler production | Higher due to labor and complexity |

Introduction to Hemp Textiles: Nonwoven vs. Woven

Nonwoven hemp textiles are created by bonding hemp fibers together through mechanical, thermal, or chemical processes, resulting in a fabric known for breathability and lightweight durability used in industrial and apparel applications. Woven hemp textiles involve interlacing warp and weft fibers on looms, producing a robust, long-lasting material favored in fashion, upholstery, and eco-friendly packaging. Both types offer sustainable alternatives with distinct textures, strengths, and versatility tailored for specific functional uses in modern textile industries.

Understanding Nonwoven Hemp Textiles

Nonwoven hemp textiles are produced by bonding hemp fibers together through mechanical, chemical, or thermal processes without weaving or knitting, resulting in a fabric with high durability, breathability, and natural resistance to moisture. These textiles are widely used in automotive interiors, geotextiles, and filtration products due to their eco-friendly properties and cost-effective production methods. Understanding nonwoven hemp textiles involves recognizing their superior insulation, biodegradability, and versatility compared to traditional woven hemp fabrics.

Advantages of Nonwoven Hemp Fabrics

Nonwoven hemp textiles offer superior breathability and moisture-wicking properties compared to woven hemp fabrics, making them ideal for applications requiring enhanced comfort and hygiene. Their production process allows for greater flexibility in fabric thickness and texture, enabling customizable durability and softness without compromising eco-friendly attributes. Nonwoven hemp fabrics also require less water and energy during manufacturing, resulting in a more sustainable and cost-effective alternative to traditional woven hemp textiles.

Exploring Woven Hemp Textiles

Woven hemp textiles are created through interlacing warp and weft yarns, resulting in a durable and strong fabric ideal for apparel, upholstery, and industrial applications. The tightly woven structure of hemp fibers enhances breathability, moisture-wicking, and thermal regulation, making woven hemp textiles suitable for eco-friendly fashion and sustainable home furnishings. Compared to nonwoven hemp, woven hemp offers superior tensile strength and longevity, contributing to its growing demand in the green textile market.

Key Benefits of Woven Hemp Fabrics

Woven hemp fabrics offer superior durability and tensile strength compared to nonwoven hemp textiles, making them ideal for long-lasting applications such as upholstery, clothing, and industrial uses. The tight interlacing of woven fibers enhances breathability and natural moisture-wicking properties, contributing to comfort and sustainability. Furthermore, woven hemp textiles provide better resistance to wear and tear, maintaining shape and texture after repeated washing and use.

Manufacturing Processes: Nonwoven vs. Woven Hemp

Nonwoven hemp textiles are produced through bonding fibers using mechanical, chemical, or thermal methods, bypassing the traditional weaving process and resulting in materials with uniform texture and enhanced durability. Woven hemp textiles involve interlacing hemp yarns in perpendicular patterns on looms, producing fabrics with high tensile strength and breathability ideal for apparel and upholstery. Manufacturing nonwoven hemp is faster and cost-effective for industrial uses, while woven hemp requires more intricate labor and offers superior flexibility and aesthetic appeal for fashion and high-quality products.

Performance Comparison: Strength, Durability, and Flexibility

Nonwoven hemp textiles exhibit superior flexibility and lightweight properties due to their random fiber orientation, making them ideal for applications requiring pliability and softness. Woven hemp textiles demonstrate higher tensile strength and enhanced durability thanks to their interlaced fiber structure, which provides resistance to wear and tear. While woven hemp fabrics excel in longevity and load-bearing performance, nonwoven variants offer better adaptability and comfort in flexible uses.

Sustainability and Environmental Impact

Nonwoven hemp textiles require less water and energy during production compared to traditional woven hemp fabrics, significantly reducing their environmental footprint. The absence of weaving processes minimizes chemical use and waste generation, enhancing overall sustainability. Both types benefit from hemp's natural biodegradability and carbon sequestration properties, but nonwovens offer a more resource-efficient alternative for eco-friendly textile manufacturing.

Common Applications: Nonwoven vs. Woven Hemp

Nonwoven hemp textiles are commonly used in automotive interiors, insulation, and geotextiles due to their durability and cost-effectiveness, providing excellent cushioning and filtration properties. Woven hemp textiles dominate in fashion, upholstery, and eco-friendly bags, prized for their strength, breathability, and aesthetic versatility. The choice between nonwoven and woven hemp depends largely on application requirements such as texture, tensile strength, and environmental impact.

Choosing the Right Hemp Textile for Your Needs

Nonwoven hemp textiles offer lightweight, breathable, and cost-effective solutions ideal for disposable or short-term applications, while woven hemp textiles provide durability, structure, and enhanced strength suited for long-term use such as upholstery and apparel. Selecting the right hemp textile depends on intended use, with nonwoven fabrics favored for insulation, geotextiles, and medical products, and woven hemp preferred for garments, bags, and durable home furnishings. Understanding the differences in texture, flexibility, and environmental impact aids in optimizing functionality and sustainability in diverse hemp textile applications.

Nonwoven Hemp Textiles vs Woven Hemp Textiles Infographic

materialdif.com

materialdif.com