Bast fibers, derived from the outer layer of the hemp stalk, are long, strong, and flexible, making them ideal for textiles, rope, and paper production. Core fibers, located in the inner woody core, are shorter and more brittle, commonly used for animal bedding, insulation, and biodegradable composites. The distinct properties of bast and core fibers enable diverse applications, enhancing the versatility and sustainability of hemp-based products.

Table of Comparison

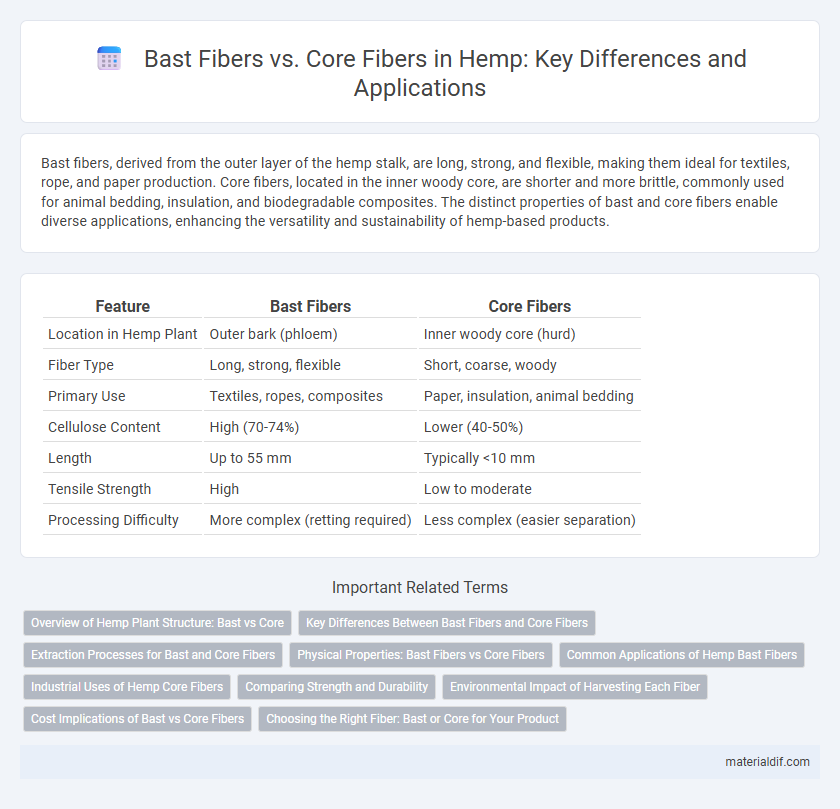

| Feature | Bast Fibers | Core Fibers |

|---|---|---|

| Location in Hemp Plant | Outer bark (phloem) | Inner woody core (hurd) |

| Fiber Type | Long, strong, flexible | Short, coarse, woody |

| Primary Use | Textiles, ropes, composites | Paper, insulation, animal bedding |

| Cellulose Content | High (70-74%) | Lower (40-50%) |

| Length | Up to 55 mm | Typically <10 mm |

| Tensile Strength | High | Low to moderate |

| Processing Difficulty | More complex (retting required) | Less complex (easier separation) |

Overview of Hemp Plant Structure: Bast vs Core

Hemp plant structure is divided into bast fibers and core fibers, each with distinct characteristics and uses. Bast fibers, located in the outer layer of the stalk, are long, strong, and flexible, making them ideal for textiles, ropes, and biocomposites. Core fibers, found in the inner woody core called the hurd, are shorter, softer, and more absorbent, commonly used in animal bedding, construction materials, and biofuel production.

Key Differences Between Bast Fibers and Core Fibers

Bast fibers, derived from the outer bark of hemp stalks, are long, strong, and flexible, making them ideal for textiles, ropes, and paper production. Core fibers, found in the inner woody core of the hemp stalk, are shorter, coarser, and primarily used for insulation, animal bedding, and biocomposites. The key differences lie in their cellular structure, fiber length, and end-use applications, with bast fibers providing durability and softness while core fibers offer bulk and thermal properties.

Extraction Processes for Bast and Core Fibers

Extraction processes for bast fibers involve retting methods such as water retting, dew retting, and enzymatic retting to break down pectins and separate the fibers from the hemp stalk's outer layer. Core fibers, also known as hurd, are typically separated using mechanical techniques like decortication, which crushes and fractures the woody inner core to release the fibers. Efficiency in extraction impacts fiber quality, with retting optimizing bast fiber strength and decortication favoring core fiber utilization for composites and construction materials.

Physical Properties: Bast Fibers vs Core Fibers

Bast fibers, derived from the outer layer of the hemp stalk, exhibit higher tensile strength and flexibility compared to core fibers, making them ideal for textile and rope applications. Core fibers, found in the inner woody core, offer greater stiffness and absorbency but lower durability, suitable for insulation and composite materials. The physical distinction lies in bast fibers' long, strong cellulose strands versus core fibers' shorter, more brittle lignin-rich structure.

Common Applications of Hemp Bast Fibers

Hemp bast fibers, known for their strength and flexibility, are commonly used in textiles, ropes, and composite materials, providing durability and eco-friendly alternatives to synthetic fibers. These fibers are integral to the production of high-quality fabrics, upholstery, and bioplastics, contributing to sustainable fashion and automotive industries. Applications also extend to paper manufacturing and insulation materials, leveraging the bast fibers' resistance and moisture-wicking properties.

Industrial Uses of Hemp Core Fibers

Hemp core fibers, also known as hurds, are primarily used in industrial applications due to their high cellulose content and absorbent properties. These fibers are ideal for manufacturing bio-composites, animal bedding, and construction materials like hempcrete, which enhances insulation and sustainability in building. Unlike bast fibers, which are longer and stronger for textiles, hemp core fibers thrive in heavy-duty and eco-friendly industrial sectors.

Comparing Strength and Durability

Bast fibers from hemp, extracted from the outer fibrous layer, exhibit superior tensile strength and durability compared to core fibers found in the inner woody core. The robust cellulose content and aligned microfibril structure in bast fibers contribute to their exceptional mechanical properties, making them ideal for textiles and composite materials. Core fibers, although less strong, provide enhanced flexibility and are often utilized in applications requiring lightweight materials and insulation.

Environmental Impact of Harvesting Each Fiber

Bast fibers from hemp, extracted from the outer stalk, require less intensive processing and produce minimal waste, resulting in a lower environmental footprint compared to core fibers, which demand more energy and chemicals for separation. Harvesting bast fibers supports sustainable agriculture by promoting higher yields per acre and reducing reliance on synthetic inputs. Core fiber extraction, often associated with pulp and insulation production, generates more byproducts and higher emissions, elevating its overall environmental impact.

Cost Implications of Bast vs Core Fibers

Bast fibers, derived from the outer stalk of hemp, typically incur higher processing costs due to labor-intensive extraction methods and the need for specialized retting techniques, which increases overall production expenses. Core fibers, sourced from the inner woody core, are cheaper to process as they require less refinement but yield lower fiber quality, limiting their use in high-value textile applications. Cost implications favor core fibers for bulk, low-cost products, while bast fibers remain preferable for premium, durable materials despite their higher price.

Choosing the Right Fiber: Bast or Core for Your Product

Bast fibers, derived from the outer stalk of the hemp plant, offer superior tensile strength and flexibility, making them ideal for textiles, ropes, and biocomposites requiring durability and softness. Core fibers, found in the inner woody core known as hurds, provide excellent insulation, absorbency, and lightweight properties suitable for construction materials, animal bedding, and paper production. Selecting bast fibers enhances product strength and texture, while core fibers optimize thermal performance and absorbency depending on the end-use requirements.

bast fibers vs core fibers Infographic

materialdif.com

materialdif.com