Hempcrete offers superior insulation and breathability compared to traditional concrete, reducing energy consumption in buildings. Its lightweight, carbon-negative properties contribute to sustainable construction by lowering the overall environmental impact. Unlike concrete, hempcrete is more flexible and resistant to cracking, enhancing the durability of structures in varying climates.

Table of Comparison

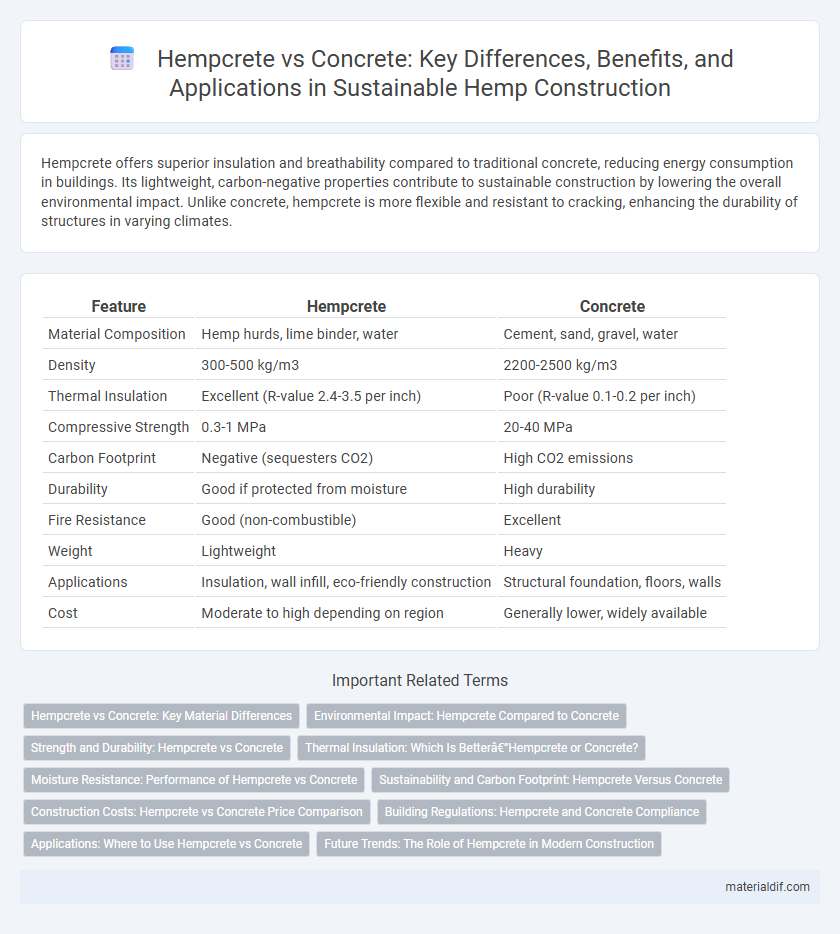

| Feature | Hempcrete | Concrete |

|---|---|---|

| Material Composition | Hemp hurds, lime binder, water | Cement, sand, gravel, water |

| Density | 300-500 kg/m3 | 2200-2500 kg/m3 |

| Thermal Insulation | Excellent (R-value 2.4-3.5 per inch) | Poor (R-value 0.1-0.2 per inch) |

| Compressive Strength | 0.3-1 MPa | 20-40 MPa |

| Carbon Footprint | Negative (sequesters CO2) | High CO2 emissions |

| Durability | Good if protected from moisture | High durability |

| Fire Resistance | Good (non-combustible) | Excellent |

| Weight | Lightweight | Heavy |

| Applications | Insulation, wall infill, eco-friendly construction | Structural foundation, floors, walls |

| Cost | Moderate to high depending on region | Generally lower, widely available |

Hempcrete vs Concrete: Key Material Differences

Hempcrete, made from hemp hurds, lime, and water, offers superior insulation properties and breathability compared to traditional concrete, reducing energy consumption in buildings. Unlike concrete, which is dense and prone to cracking, hempcrete is lightweight, flexible, and resistant to mold and pests, enhancing structural longevity. Hempcrete's carbon-negative footprint contrasts sharply with concrete's high carbon emissions during production, positioning it as an eco-friendly alternative in sustainable construction.

Environmental Impact: Hempcrete Compared to Concrete

Hempcrete significantly reduces carbon emissions by absorbing CO2 during hemp cultivation, making it a carbon-negative building material compared to traditional concrete, which is a major source of global CO2 emissions due to cement production. The production of hempcrete consumes less energy and generates minimal pollution, while concrete manufacturing requires high temperatures and extensive fossil fuel use. Hempcrete also offers superior biodegradability and insulation properties, contributing to lower operational energy consumption and overall environmental footprint.

Strength and Durability: Hempcrete vs Concrete

Hempcrete offers superior insulation and breathability but has significantly lower compressive strength compared to traditional concrete, making it less suitable for load-bearing structures. Concrete demonstrates high durability and strength with a compressive capacity typically ranging from 20 to 40 MPa, whereas hempcrete's compressive strength is generally below 1 MPa. Despite its lower strength, hempcrete provides excellent resistance to mold, pests, and fire, contributing to long-term durability in non-structural applications.

Thermal Insulation: Which Is Better—Hempcrete or Concrete?

Hempcrete offers superior thermal insulation compared to traditional concrete due to its low thermal conductivity, which ranges between 0.05 and 0.12 W/mK. This natural composite helps maintain stable indoor temperatures, reducing heating and cooling energy consumption by up to 30%. Concrete, with a higher thermal conductivity of around 1.4 W/mK, lacks the insulating properties necessary for efficient temperature regulation in buildings.

Moisture Resistance: Performance of Hempcrete vs Concrete

Hempcrete exhibits superior moisture resistance compared to traditional concrete due to its natural ability to regulate humidity by absorbing and releasing moisture without deteriorating. Concrete, while strong and durable, is prone to cracking and spalling when exposed to prolonged moisture or freeze-thaw cycles, leading to potential structural damage. The breathable nature of hempcrete reduces the risk of mold growth and damp-related issues, making it an ideal sustainable alternative for moisture-prone environments.

Sustainability and Carbon Footprint: Hempcrete Versus Concrete

Hempcrete significantly outperforms traditional concrete in sustainability and carbon footprint, as it is made from renewable hemp fibers and limestone binder that absorb CO2 during curing, effectively acting as a carbon sink. In contrast, concrete production involves high CO2 emissions due to the energy-intensive calcination of limestone, accounting for approximately 8% of global carbon emissions. Using hempcrete reduces environmental impact by lowering embodied carbon and promoting biodegradable, non-toxic building materials that contribute to healthier indoor air quality.

Construction Costs: Hempcrete vs Concrete Price Comparison

Hempcrete construction typically incurs higher initial material costs than traditional concrete due to the specialized processing of hemp fibers and lime binder. However, hempcrete offers long-term savings through reduced insulation and maintenance expenses, potentially offsetting its upfront price over the building's lifespan. Concrete remains more cost-effective for large-scale projects, but hempcrete's sustainability benefits and energy efficiency are driving increased adoption despite price differences.

Building Regulations: Hempcrete and Concrete Compliance

Hempcrete meets many modern building regulations due to its excellent thermal insulation, vapor permeability, and fire resistance, making it compliant with sustainable construction standards in several countries. Concrete, while widely accepted in building codes globally, often requires additives or treatments to address thermal performance and environmental impact issues, which can affect regulatory compliance. Building regulations increasingly favor hempcrete for green construction projects due to its carbon-negative properties and ability to improve indoor air quality, positioning it as a compliant alternative to traditional concrete in eco-friendly building certifications.

Applications: Where to Use Hempcrete vs Concrete

Hempcrete excels in insulating walls, floors, and roofs, offering superior thermal regulation and moisture control ideal for eco-friendly residential and commercial buildings. Concrete is preferred for structural applications such as foundations, load-bearing walls, bridges, and roads due to its high compressive strength and durability. In construction projects prioritizing sustainability and energy efficiency, hempcrete provides a lightweight, breathable alternative, while concrete remains essential where structural integrity and heavy load resistance are critical.

Future Trends: The Role of Hempcrete in Modern Construction

Hempcrete is rapidly gaining traction as a sustainable alternative to traditional concrete in modern construction due to its carbon-negative properties and excellent thermal insulation. Innovations in hempcrete formulation enhance durability and fire resistance, positioning it as a key material in green building standards and zero-energy housing. The growing emphasis on reducing construction-related carbon emissions drives the future adoption of hempcrete in urban development and eco-friendly infrastructure projects.

hempcrete vs concrete Infographic

materialdif.com

materialdif.com