Hemp oil finish penetrates deeply into wood, enhancing its natural texture and providing a non-toxic, eco-friendly protective layer ideal for hemp pet accessories. Polyurethane finish creates a hard, durable surface that offers superior water and scratch resistance but may contain chemicals less suitable for sensitive pets. Choosing hemp oil finish supports sustainability and safety, while polyurethane finish prioritizes long-lasting durability.

Table of Comparison

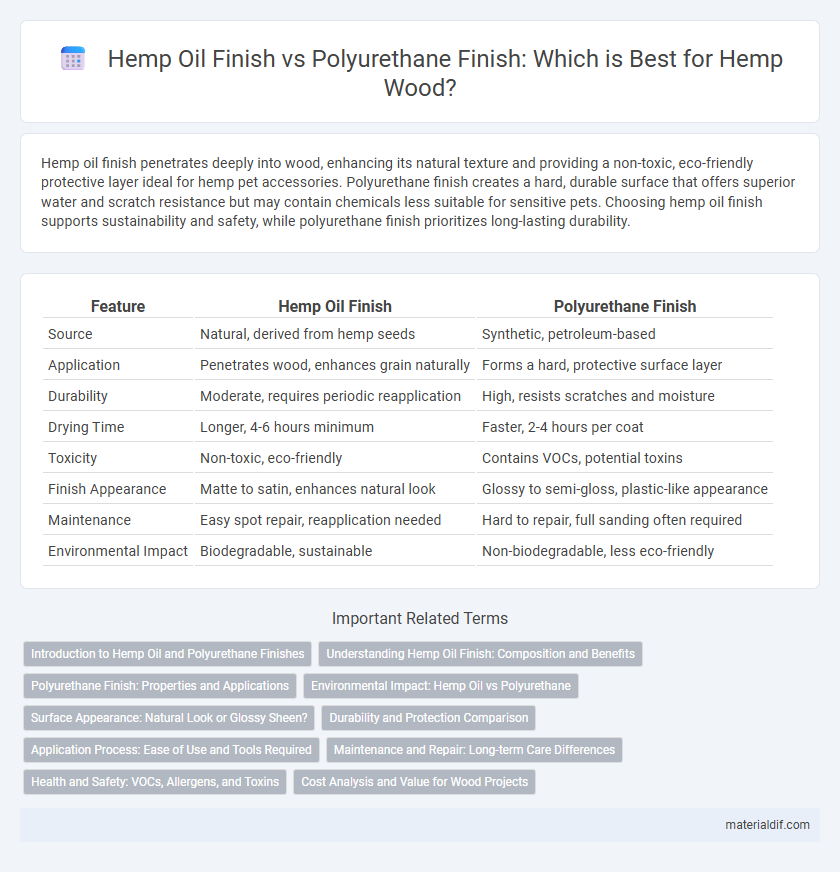

| Feature | Hemp Oil Finish | Polyurethane Finish |

|---|---|---|

| Source | Natural, derived from hemp seeds | Synthetic, petroleum-based |

| Application | Penetrates wood, enhances grain naturally | Forms a hard, protective surface layer |

| Durability | Moderate, requires periodic reapplication | High, resists scratches and moisture |

| Drying Time | Longer, 4-6 hours minimum | Faster, 2-4 hours per coat |

| Toxicity | Non-toxic, eco-friendly | Contains VOCs, potential toxins |

| Finish Appearance | Matte to satin, enhances natural look | Glossy to semi-gloss, plastic-like appearance |

| Maintenance | Easy spot repair, reapplication needed | Hard to repair, full sanding often required |

| Environmental Impact | Biodegradable, sustainable | Non-biodegradable, less eco-friendly |

Introduction to Hemp Oil and Polyurethane Finishes

Hemp oil finish is a natural, eco-friendly wood treatment derived from cold-pressed hemp seeds, known for enhancing wood grain while providing water resistance and a non-toxic coating. Polyurethane finish, a synthetic polymer, creates a durable, glossy or matte protective layer that offers superior abrasion and chemical resistance on wood surfaces. Understanding the differences in composition and performance helps in selecting an appropriate finish for furniture, flooring, or decorative wood applications.

Understanding Hemp Oil Finish: Composition and Benefits

Hemp oil finish is derived from cold-pressed hemp seeds, rich in essential fatty acids and natural antioxidants, making it an eco-friendly and non-toxic option for wood finishing. Its composition allows deep penetration into the wood, enhancing grain visibility while providing a flexible, breathable layer that resists water and wear without trapping moisture. Compared to polyurethane finishes, hemp oil maintains the wood's natural appearance and requires periodic reapplication, promoting long-term maintenance with minimal environmental impact.

Polyurethane Finish: Properties and Applications

Polyurethane finish offers a durable, water-resistant coating commonly used on wood surfaces to protect against scratches, chemicals, and everyday wear. Its ability to create a hard, glossy, or matte surface makes it ideal for flooring, furniture, and cabinetry, providing long-lasting protection compared to natural finishes like hemp oil. The synthetic composition of polyurethane enhances resistance to heat and UV light, ensuring extended preservation of the treated material's appearance and structural integrity.

Environmental Impact: Hemp Oil vs Polyurethane

Hemp oil finish is biodegradable and derived from renewable plant sources, significantly reducing environmental pollution during production and disposal compared to petroleum-based polyurethane finishes. Polyurethane releases volatile organic compounds (VOCs) and heavy metals, contributing to air and water pollution and posing health hazards. Choosing hemp oil finish supports sustainable forestry practices and lowers the carbon footprint associated with wood treatment products.

Surface Appearance: Natural Look or Glossy Sheen?

Hemp oil finish enhances wood with a natural, matte appearance that highlights grain texture and provides a warm, organic feel without gloss. Polyurethane finish creates a durable, glossy sheen that reflects light, offering a smooth, polished surface ideal for high-traffic areas. Choosing between hemp oil and polyurethane depends on whether a natural, understated look or a shiny, protective coat is preferred for the wood surface.

Durability and Protection Comparison

Hemp oil finish penetrates deeply into wood fibers, providing natural resistance to water and wear while maintaining breathability and enhancing the material's texture. Polyurethane finish forms a hard, protective layer on the surface, offering superior durability against scratches, chemicals, and heavy traffic but may trap moisture beneath the surface. For long-term protection in high-use areas, polyurethane is more resilient, whereas hemp oil is ideal for preserving wood's natural look with moderate durability.

Application Process: Ease of Use and Tools Required

Hemp oil finish requires minimal surface preparation and can be applied easily with a brush, cloth, or sponge, promoting deeper penetration into wood fibers and enhancing natural grain without complex tools. Polyurethane finish demands more thorough sanding between coats and typically needs high-quality brushes or spray equipment to ensure a smooth, durable layer, making the application process more labor-intensive. The simplicity of applying hemp oil with basic tools appeals to DIY enthusiasts, whereas polyurethane suits projects requiring a tougher, protective barrier despite its more involved procedure.

Maintenance and Repair: Long-term Care Differences

Hemp oil finish requires regular reapplication every few months to maintain its protective properties and can be spot-treated easily for scratches or stains, offering excellent long-term care with minimal surface buildup. Polyurethane finish provides a durable, hard protective layer that resists moisture and wear for years but can be challenging to repair since damage often requires sanding and recoating the entire surface. Hemp oil's natural, breathable qualities promote easier maintenance without trapping dirt or peeling, while polyurethane's synthetic film may crack or yellow over time, complicating long-term upkeep.

Health and Safety: VOCs, Allergens, and Toxins

Hemp oil finish contains minimal volatile organic compounds (VOCs) and is free from synthetic chemicals, reducing indoor air pollution and allergen exposure compared to polyurethane finishes. Polyurethane coatings emit higher levels of VOCs during application and curing, posing respiratory risks and potential toxic effects long-term. Using hemp oil thus promotes a safer environment by minimizing harmful emissions and avoiding allergens commonly found in petroleum-based finishes.

Cost Analysis and Value for Wood Projects

Hemp oil finish typically costs less upfront compared to polyurethane, offering an eco-friendly, biodegradable option with moderate durability ideal for small to medium wood projects. Polyurethane finish demands a higher initial investment but provides superior protection, longevity, and water resistance, making it more cost-effective for high-traffic or outdoor woodworking. Evaluating project scope and environmental impact guides optimal choice between the affordable, natural hemp oil finish and the robust, long-lasting polyurethane finish.

hemp oil finish vs polyurethane finish Infographic

materialdif.com

materialdif.com