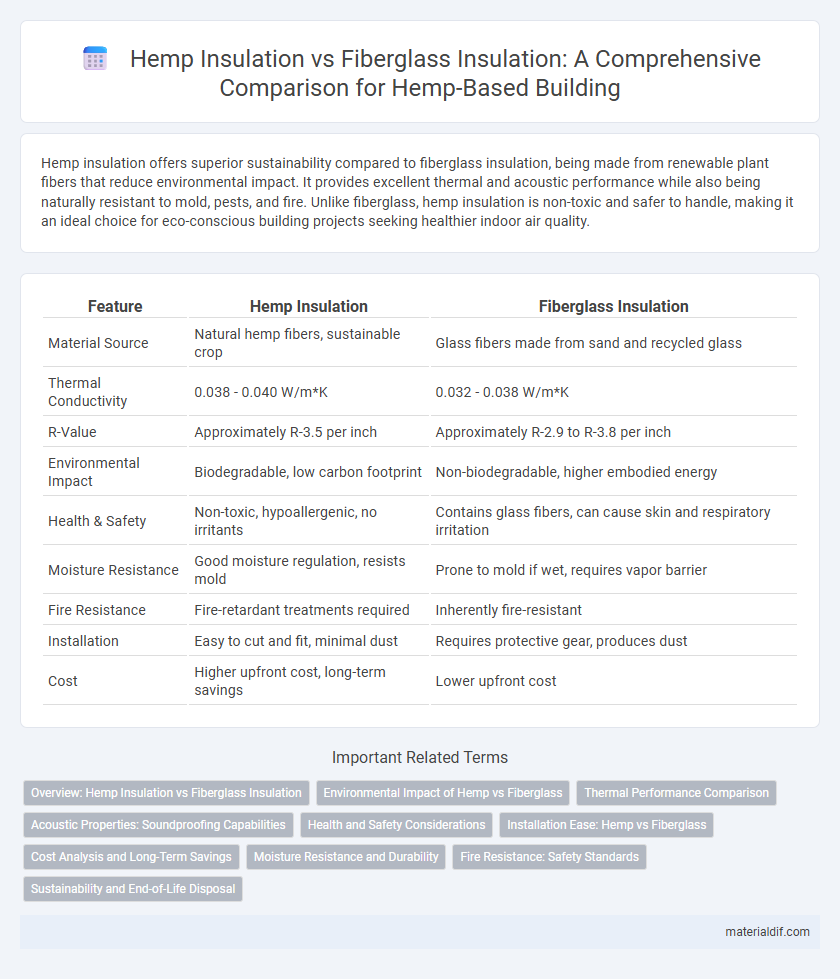

Hemp insulation offers superior sustainability compared to fiberglass insulation, being made from renewable plant fibers that reduce environmental impact. It provides excellent thermal and acoustic performance while also being naturally resistant to mold, pests, and fire. Unlike fiberglass, hemp insulation is non-toxic and safer to handle, making it an ideal choice for eco-conscious building projects seeking healthier indoor air quality.

Table of Comparison

| Feature | Hemp Insulation | Fiberglass Insulation |

|---|---|---|

| Material Source | Natural hemp fibers, sustainable crop | Glass fibers made from sand and recycled glass |

| Thermal Conductivity | 0.038 - 0.040 W/m*K | 0.032 - 0.038 W/m*K |

| R-Value | Approximately R-3.5 per inch | Approximately R-2.9 to R-3.8 per inch |

| Environmental Impact | Biodegradable, low carbon footprint | Non-biodegradable, higher embodied energy |

| Health & Safety | Non-toxic, hypoallergenic, no irritants | Contains glass fibers, can cause skin and respiratory irritation |

| Moisture Resistance | Good moisture regulation, resists mold | Prone to mold if wet, requires vapor barrier |

| Fire Resistance | Fire-retardant treatments required | Inherently fire-resistant |

| Installation | Easy to cut and fit, minimal dust | Requires protective gear, produces dust |

| Cost | Higher upfront cost, long-term savings | Lower upfront cost |

Overview: Hemp Insulation vs Fiberglass Insulation

Hemp insulation offers superior breathability and natural resistance to mold and pests compared to fiberglass insulation, which is typically made from synthetic materials and glass fibers. Hemp provides excellent thermal regulation, reducing energy costs and improving indoor air quality, while fiberglass insulation is prone to irritation and potential health hazards during installation. The eco-friendly, biodegradable nature of hemp insulation contrasts with the non-renewable, petroleum-based components found in fiberglass products.

Environmental Impact of Hemp vs Fiberglass

Hemp insulation outperforms fiberglass insulation by offering a significantly lower environmental footprint due to its renewable sourcing and biodegradability. Hemp cultivation requires less energy, water, and synthetic chemicals compared to fiberglass production, which relies heavily on fossil fuels and generates non-recyclable waste. The carbon sequestration properties of hemp further reduce greenhouse gas emissions, making it a more sustainable choice for eco-conscious construction projects.

Thermal Performance Comparison

Hemp insulation offers superior thermal performance compared to fiberglass due to its natural fiber structure, which provides enhanced breathability and better moisture regulation, reducing the risk of condensation and mold growth. Its R-value, typically ranging from 3.5 to 3.8 per inch, competes closely with fiberglass, which averages around 2.9 to 3.8 per inch, making hemp a sustainable and efficient alternative. The natural density of hemp fibers also contributes to improved thermal mass, enhancing energy efficiency in both heating and cooling applications.

Acoustic Properties: Soundproofing Capabilities

Hemp insulation offers superior acoustic properties compared to fiberglass insulation by effectively absorbing and dampening airborne noise due to its dense, fibrous structure. Studies show hemp insulation can reduce sound transmission loss by up to 10 decibels more than traditional fiberglass, making it ideal for soundproofing applications in residential and commercial buildings. Its natural composition also prevents sound vibrations from passing through walls, enhancing overall acoustic comfort and reducing noise pollution indoors.

Health and Safety Considerations

Hemp insulation offers superior health benefits compared to fiberglass insulation due to its natural, non-toxic properties and absence of irritating fibers. Unlike fiberglass, which can cause respiratory issues and skin irritation during installation and exposure, hemp insulation is hypoallergenic and biodegradable, promoting a safer indoor environment. Moreover, hemp's natural resistance to mold and pests enhances long-term safety by reducing potential health hazards associated with mold growth in damp conditions.

Installation Ease: Hemp vs Fiberglass

Hemp insulation offers a simpler and cleaner installation process compared to fiberglass insulation, as it is less irritating to the skin and lungs, reducing the need for extensive protective gear. Unlike fiberglass, hemp can be easily cut and fitted into irregular spaces without losing its insulating properties, ensuring a more efficient and precise installation. Its natural, dense fibers also help minimize dust generation during installation, improving indoor air quality and worker comfort.

Cost Analysis and Long-Term Savings

Hemp insulation typically costs 10-20% more upfront than fiberglass insulation but offers superior durability and moisture resistance, reducing replacement and maintenance expenses over time. Its natural thermal and acoustic properties enhance energy efficiency, leading to potential savings of up to 15% on heating and cooling bills annually compared to standard fiberglass. Investing in hemp insulation supports long-term financial benefits by minimizing energy consumption and prolonging insulation lifespan.

Moisture Resistance and Durability

Hemp insulation offers superior moisture resistance compared to fiberglass insulation, as it naturally regulates humidity and resists mold growth, reducing the risk of structural damage. Its durability stems from its strong, flexible fibers that maintain effectiveness over time without breaking down or compressing like fiberglass. Hemp insulation's ability to retain performance in damp conditions makes it a sustainable and long-lasting choice for eco-friendly building projects.

Fire Resistance: Safety Standards

Hemp insulation exhibits superior fire resistance compared to traditional fiberglass insulation, as it naturally chars rather than melts when exposed to high temperatures, reducing fire spread risk. Hemp fibers comply with stringent safety standards such as ASTM E84, showing lower flame spread and smoke density ratings. This makes hemp insulation a safer choice for enhancing building fire safety without compromising environmental benefits.

Sustainability and End-of-Life Disposal

Hemp insulation outperforms fiberglass insulation in sustainability by using renewable hemp fibers that absorb CO2 during growth and require less energy to produce. At the end of its life cycle, hemp insulation is biodegradable and can be composted, minimizing landfill waste, whereas fiberglass insulation is non-biodegradable and often ends up in landfills, posing environmental hazards. Choosing hemp insulation supports circular economy principles and reduces the overall environmental footprint of building materials.

hemp insulation vs fiberglass insulation Infographic

materialdif.com

materialdif.com