Cellulose extraction from hemp pet fibers produces a pure, biodegradable material ideal for packaging and composite applications due to its high tensile strength and flexibility. Lignin extraction, on the other hand, yields a natural polymer rich in antioxidant properties, making it suitable for bio-based adhesives and UV-resistant coatings. Understanding the differences in extraction methods helps optimize hemp pet's use in sustainable industries by balancing mechanical performance and functional benefits.

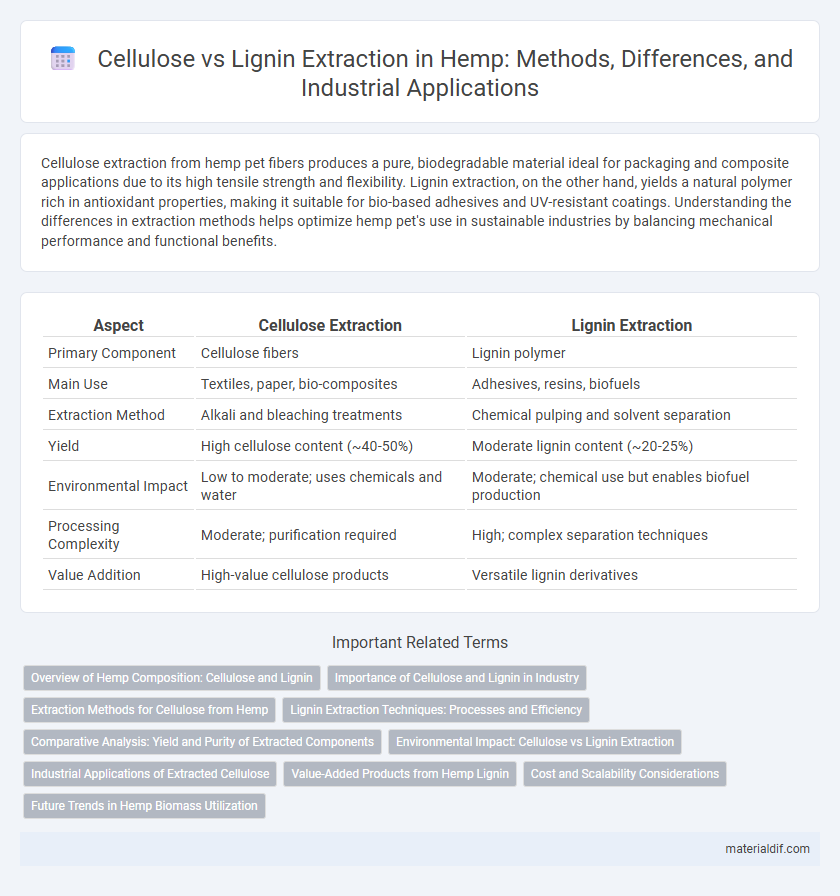

Table of Comparison

| Aspect | Cellulose Extraction | Lignin Extraction |

|---|---|---|

| Primary Component | Cellulose fibers | Lignin polymer |

| Main Use | Textiles, paper, bio-composites | Adhesives, resins, biofuels |

| Extraction Method | Alkali and bleaching treatments | Chemical pulping and solvent separation |

| Yield | High cellulose content (~40-50%) | Moderate lignin content (~20-25%) |

| Environmental Impact | Low to moderate; uses chemicals and water | Moderate; chemical use but enables biofuel production |

| Processing Complexity | Moderate; purification required | High; complex separation techniques |

| Value Addition | High-value cellulose products | Versatile lignin derivatives |

Overview of Hemp Composition: Cellulose and Lignin

Hemp biomass consists primarily of cellulose and lignin, with cellulose making up about 70-75% of the fiber content, providing structural strength and flexibility. Lignin accounts for approximately 5-15% of hemp's composition, serving as a rigid, complex polymer that binds cellulose fibers and adds resistance to microbial attack. Efficient extraction of cellulose focuses on isolating long polymer chains for textiles and composites, while lignin extraction targets its use in biofuels, adhesives, and bioplastics, highlighting their distinct industrial applications.

Importance of Cellulose and Lignin in Industry

Cellulose is a crucial biopolymer extracted from hemp, widely valued in the textile, paper, and biofuel industries due to its high strength, biodegradability, and renewable nature. Lignin, another key component, plays an essential role in providing rigidity to plant cell walls and is increasingly utilized in the production of bio-based adhesives, carbon fibers, and as a renewable alternative in the chemical industry. Efficient extraction techniques for cellulose and lignin from hemp biomass significantly impact the sustainability and economic viability of industrial applications by enabling the development of eco-friendly materials and energy solutions.

Extraction Methods for Cellulose from Hemp

Extraction methods for cellulose from hemp primarily involve chemical processes such as alkaline treatment and bleaching, which remove lignin and hemicellulose to isolate pure cellulose fibers. Enzymatic hydrolysis offers a greener alternative by selectively breaking down non-cellulosic components while preserving fiber integrity. Mechanical approaches like steam explosion and ultrasonication assist in disrupting hemp biomass, enhancing cellulose accessibility for industrial applications.

Lignin Extraction Techniques: Processes and Efficiency

Lignin extraction techniques primarily involve processes such as organosolv, steam explosion, and alkaline pretreatment, each varying in efficiency based on feedstock and operational conditions. Organosolv methods use organic solvents to dissolve lignin selectively, achieving high purity and improved extraction rates, while steam explosion disrupts the biomass structure for enhanced lignin recovery. Alkaline pretreatment employs bases like sodium hydroxide to solubilize lignin, balancing extraction yield and structural preservation, crucial for downstream applications in hemp processing.

Comparative Analysis: Yield and Purity of Extracted Components

Hemp cellulose extraction typically yields a higher purity product with minimal contamination, making it ideal for applications requiring strong, biodegradable fibers and films. Lignin extraction from hemp, while producing lower purity fractions often mixed with residual polysaccharides, offers valuable phenolic compounds for bio-based adhesives and resins. Comparative analysis highlights that cellulose extraction favors consistency and high yield of pure polysaccharide content, whereas lignin extraction prioritizes recovering complex aromatic structures despite lower purity and variable yields.

Environmental Impact: Cellulose vs Lignin Extraction

Cellulose extraction from hemp fibers typically involves fewer harmful chemicals and generates less toxic waste compared to lignin extraction, making it more environmentally sustainable. Lignin extraction processes often require harsh solvents and intensive energy use, leading to higher emissions and greater ecological disruption. Prioritizing cellulose over lignin extraction reduces the carbon footprint and improves biodegradability in hemp-based product manufacturing.

Industrial Applications of Extracted Cellulose

Extracted cellulose from hemp serves as a vital raw material in various industrial applications such as the production of biodegradable plastics, textiles, and paper products, thanks to its high purity and strength. Its remarkable fiber properties enable the manufacture of composite materials used in automotive and construction industries, offering sustainable alternatives to traditional resources. The versatility and renewability of hemp-derived cellulose contribute significantly to eco-friendly innovations and the reduction of reliance on fossil-fuel-based products.

Value-Added Products from Hemp Lignin

Hemp lignin extraction yields valuable biopolymers with applications in adhesives, composites, and biofuels, offering higher commercial potential compared to cellulose. Advanced techniques such as organosolv and enzymatic extraction enhance lignin purity, enabling its use in producing sustainable materials like carbon fibers and antioxidants. These value-added products from hemp lignin contribute significantly to the development of green chemistry and circular bioeconomy industries.

Cost and Scalability Considerations

Cellulose extraction from hemp is generally more cost-effective and scalable due to established industrial processes and the higher market demand for cellulose-based products like paper and textiles. Lignin extraction, while valuable for bio-based chemicals and materials, involves more complex purification steps that increase production costs and limit large-scale adoption. Scalability challenges for lignin stem from its heterogeneous composition and the need for advanced separation technologies, making cellulose extraction the preferred choice for commercial hemp processing.

Future Trends in Hemp Biomass Utilization

Future trends in hemp biomass utilization emphasize advanced cellulose extraction techniques to produce high-purity fibers for sustainable textiles and bio-composites, driven by innovations in enzymatic and chemical processing. Simultaneously, lignin extraction is gaining attention for its potential in bio-based adhesives, resins, and carbon fiber production, leveraging its natural aromatic polymer structure. Emerging integrated biorefineries aim to optimize the simultaneous recovery of cellulose and lignin, maximizing material efficiency and enabling a zero-waste hemp processing paradigm.

Cellulose Extraction vs Lignin Extraction Infographic

materialdif.com

materialdif.com