Hemp oil finish penetrates deep into wood fibers, providing a natural, non-toxic protection that enhances grain and resists moisture without creating a surface film. Synthetic finishes form a protective layer on the surface, offering stronger resistance to scratches and chemicals but can peel or crack over time. Choosing hemp oil finish supports eco-friendly practices and ease of maintenance, while synthetic finishes deliver longer-lasting durability in high-traffic areas.

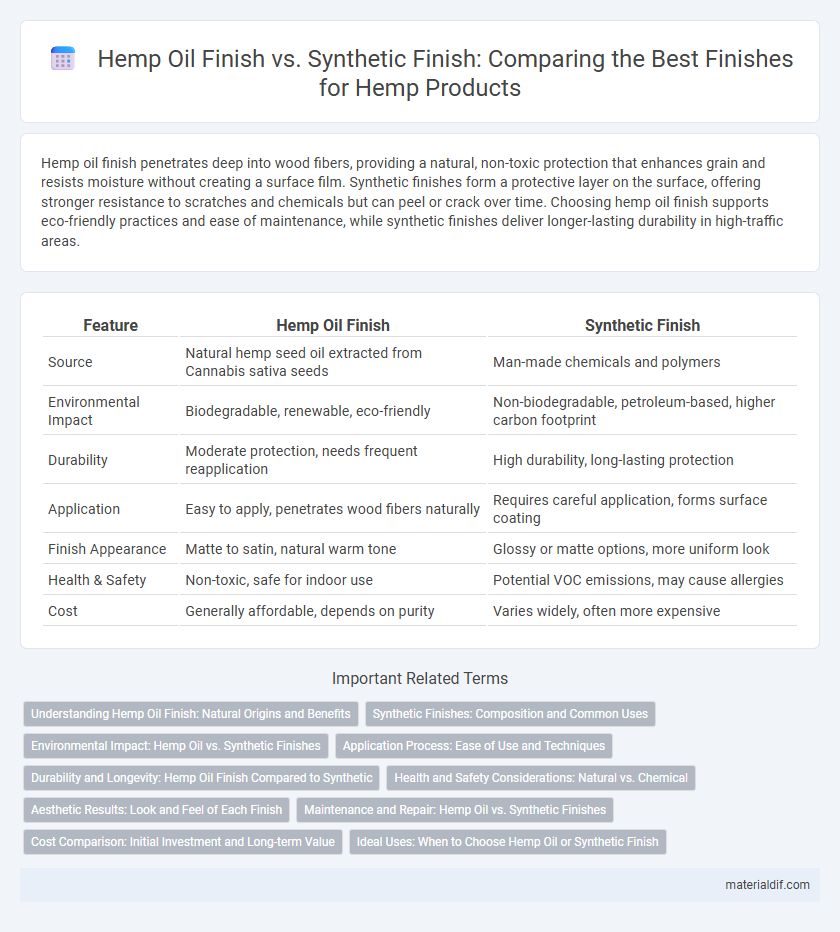

Table of Comparison

| Feature | Hemp Oil Finish | Synthetic Finish |

|---|---|---|

| Source | Natural hemp seed oil extracted from Cannabis sativa seeds | Man-made chemicals and polymers |

| Environmental Impact | Biodegradable, renewable, eco-friendly | Non-biodegradable, petroleum-based, higher carbon footprint |

| Durability | Moderate protection, needs frequent reapplication | High durability, long-lasting protection |

| Application | Easy to apply, penetrates wood fibers naturally | Requires careful application, forms surface coating |

| Finish Appearance | Matte to satin, natural warm tone | Glossy or matte options, more uniform look |

| Health & Safety | Non-toxic, safe for indoor use | Potential VOC emissions, may cause allergies |

| Cost | Generally affordable, depends on purity | Varies widely, often more expensive |

Understanding Hemp Oil Finish: Natural Origins and Benefits

Hemp oil finish, derived from cold-pressed hemp seeds, offers a natural, non-toxic alternative to synthetic finishes by deeply penetrating wood fibers to enhance durability and moisture resistance. Rich in essential fatty acids and antioxidants, hemp oil provides a breathable barrier that preserves the material's natural appearance while promoting longevity. Unlike synthetic finishes that rely on chemical compounds, hemp oil supports eco-friendly applications with superior biodegradability and minimal environmental impact.

Synthetic Finishes: Composition and Common Uses

Synthetic finishes are primarily composed of petrochemical-based polymers such as polyurethane, acrylics, and epoxy resins, engineered to provide durable, water-resistant, and UV-stable coatings. These finishes are commonly used in industrial applications, furniture manufacturing, and flooring to enhance surface protection and longevity. Compared to hemp oil finishes, synthetic finishes offer higher chemical resistance and faster drying times but lack the natural, eco-friendly characteristics of plant-based oils.

Environmental Impact: Hemp Oil vs. Synthetic Finishes

Hemp oil finishes offer a sustainable and biodegradable alternative to synthetic finishes, significantly reducing environmental pollution through their natural origin and lower VOC emissions. Synthetic finishes, often petroleum-based, contribute to chemical runoff and persist in ecosystems, posing long-term hazards to soil and water quality. Choosing hemp oil finish supports eco-friendly practices by enhancing wood protection while minimizing ecological footprints.

Application Process: Ease of Use and Techniques

Hemp oil finish requires simple application techniques, often involving straightforward brushing or wiping, allowing easy penetration into wood surfaces for a natural, breathable finish. Synthetic finishes typically need more precise application methods with specialized tools and drying times, which can complicate the process for novices. The ease of use of hemp oil finish suits DIY projects, while synthetic finishes often demand professional skills for optimal results.

Durability and Longevity: Hemp Oil Finish Compared to Synthetic

Hemp oil finish penetrates deeply into wood fibers, providing a natural barrier that enhances durability by resisting cracking and drying over time. Unlike synthetic finishes, hemp oil allows the wood to breathe, which helps maintain longevity without peeling or flaking. This natural finish improves with age, offering sustained protection and richer color development compared to synthetic alternatives.

Health and Safety Considerations: Natural vs. Chemical

Hemp oil finish, derived from natural plant extracts, offers non-toxic, biodegradable properties that reduce health risks such as skin irritation and respiratory issues during application and use. Synthetic finishes often contain volatile organic compounds (VOCs) and harmful chemicals that can off-gas toxic fumes, posing long-term health hazards and environmental concerns. Choosing hemp oil finish supports safer indoor air quality and minimizes exposure to carcinogens and allergens commonly found in chemical-based coatings.

Aesthetic Results: Look and Feel of Each Finish

Hemp oil finish imparts a natural, matte sheen that enhances wood grain while preserving its organic texture, creating a warm and earthy appearance. Synthetic finishes offer a broader range of gloss levels, including high-gloss and satin, providing a more uniform and polished look but often at the expense of tactile warmth. The breathable quality of hemp oil allows wood to age gracefully with subtle patina, whereas synthetic finishes tend to mask natural aging and can become brittle or crack over time.

Maintenance and Repair: Hemp Oil vs. Synthetic Finishes

Hemp oil finish penetrates wood fibers, nourishing and enhancing natural grain while allowing easy spot repairs with additional oil applications, making maintenance straightforward and eco-friendly. Synthetic finishes create a durable, protective surface film that resists stains and scratches but often requires sanding or complete refinishing for repairs, resulting in more labor-intensive upkeep. Regular reapplication of hemp oil maintains its moisture barrier, whereas synthetic finishes demand less frequent but more involved restoration processes when damaged.

Cost Comparison: Initial Investment and Long-term Value

Hemp oil finish generally requires a higher initial investment due to its natural extraction and processing methods, but offers long-term value through its eco-friendly, biodegradable properties and ability to naturally protect wood surfaces. Synthetic finishes tend to have lower upfront costs but may incur higher long-term expenses related to chemical degradation, environmental disposal fees, and more frequent reapplications. Choosing hemp oil finish supports sustainable sourcing and reduces overall maintenance costs, making it economically advantageous over time despite the initial price difference.

Ideal Uses: When to Choose Hemp Oil or Synthetic Finish

Hemp oil finish is ideal for natural wood surfaces and furniture requiring a non-toxic, eco-friendly coating that enhances grain while providing moderate water resistance. Synthetic finishes excel in high-traffic or outdoor applications needing durable, long-lasting protection against moisture, UV rays, and chemicals. Choose hemp oil for sustainability and breathability; opt for synthetic finishes when prioritizing toughness and extended lifespan in harsh environments.

Hemp oil finish vs Synthetic finish Infographic

materialdif.com

materialdif.com