CO2 extraction delivers a cleaner and more precise hemp concentrate by utilizing pressurized carbon dioxide to isolate cannabinoids without residual solvents, making it ideal for high-quality, pure extracts. Ethanol extraction, while more cost-effective and efficient in large-scale operations, tends to co-extract chlorophyll and other plant compounds, which may require additional refining to achieve the same level of purity. Choosing between CO2 and ethanol extraction depends on the desired product quality, production scale, and budget constraints.

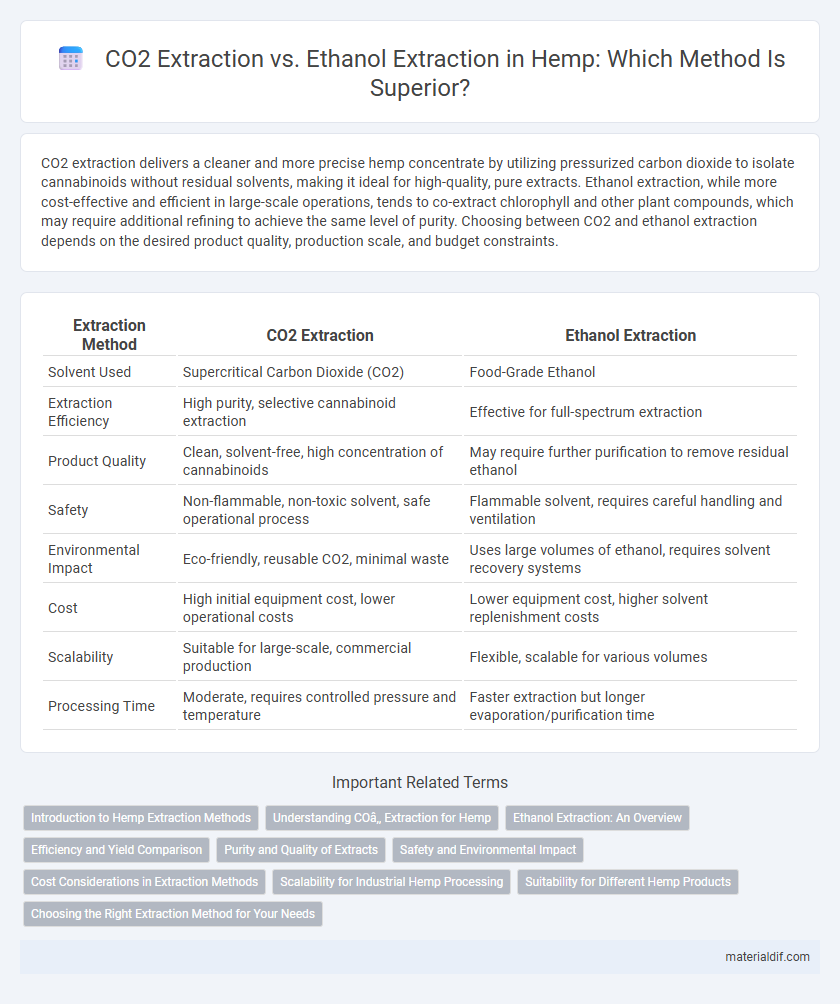

Table of Comparison

| Extraction Method | CO2 Extraction | Ethanol Extraction |

|---|---|---|

| Solvent Used | Supercritical Carbon Dioxide (CO2) | Food-Grade Ethanol |

| Extraction Efficiency | High purity, selective cannabinoid extraction | Effective for full-spectrum extraction |

| Product Quality | Clean, solvent-free, high concentration of cannabinoids | May require further purification to remove residual ethanol |

| Safety | Non-flammable, non-toxic solvent, safe operational process | Flammable solvent, requires careful handling and ventilation |

| Environmental Impact | Eco-friendly, reusable CO2, minimal waste | Uses large volumes of ethanol, requires solvent recovery systems |

| Cost | High initial equipment cost, lower operational costs | Lower equipment cost, higher solvent replenishment costs |

| Scalability | Suitable for large-scale, commercial production | Flexible, scalable for various volumes |

| Processing Time | Moderate, requires controlled pressure and temperature | Faster extraction but longer evaporation/purification time |

Introduction to Hemp Extraction Methods

CO2 extraction and ethanol extraction are two prevalent methods for isolating cannabinoids and terpenes from hemp. CO2 extraction utilizes supercritical carbon dioxide to produce pure, high-quality hemp extracts with minimal solvent residues, known for preserving delicate compounds. Ethanol extraction employs food-grade alcohol to efficiently extract a broad spectrum of phytochemicals, offering a cost-effective and scalable solution for hemp processing.

Understanding CO₂ Extraction for Hemp

CO2 extraction uses supercritical carbon dioxide to efficiently separate cannabinoids and terpenes from hemp plant material without leaving harmful residues, ensuring a pure and potent product. This method operates under precise temperature and pressure controls, preserving delicate compounds and enhancing the overall quality of hemp extracts. Compared to ethanol extraction, CO2 extraction offers superior selectivity and environmental benefits, making it a preferred technique in hemp processing.

Ethanol Extraction: An Overview

Ethanol extraction in hemp processing efficiently isolates cannabinoids and terpenes by using ethanol as a solvent, which is food-grade and safe for human consumption. This method operates effectively at low temperatures, preserving the plant's chemical profile while enabling high-yield extraction of CBD and other active compounds. Compared to CO2 extraction, ethanol extraction is faster and more cost-effective, though it may require additional purification steps to remove chlorophyll and other impurities.

Efficiency and Yield Comparison

CO2 extraction delivers higher purity hemp oil with efficient separation of cannabinoids and terpenes, resulting in a more concentrated product and consistent yield. Ethanol extraction, while faster and lower in cost, often extracts more chlorophyll and other plant impurities, which can reduce the overall quality and require additional refining steps. CO2 extraction's precision and control make it superior for maximizing cannabinoid yield and preserving terpene profiles compared to ethanol methods.

Purity and Quality of Extracts

CO2 extraction delivers high-purity hemp extracts by using controlled temperature and pressure, which preserves sensitive cannabinoids and terpenes without solvent residues. Ethanol extraction, while effective at extracting a broad spectrum of compounds, often requires additional refining steps to remove chlorophyll and other impurities, potentially affecting overall extract quality. The precision of CO2 extraction generally leads to superior quality hemp products with cleaner taste profiles and consistent cannabinoid concentrations.

Safety and Environmental Impact

CO2 extraction offers a safer alternative due to its non-toxic, non-flammable nature and ability to operate at lower temperatures, minimizing the risk of explosions and thermal degradation of cannabinoids. Ethanol extraction, while efficient, involves flammable solvents that require stringent handling protocols to prevent fire hazards and potential chemical residues in the final product. Environmentally, CO2 extraction is more sustainable as it uses recyclable CO2 without generating hazardous waste, whereas ethanol extraction can result in solvent emissions and increased energy consumption during recovery processes.

Cost Considerations in Extraction Methods

CO2 extraction typically involves higher initial equipment costs but offers lower long-term operational expenses due to its efficiency and solvent recovery capabilities. Ethanol extraction requires lower upfront investment but incurs higher ongoing costs from solvent purchase and disposal, as well as increased safety measures. Evaluating cost considerations in hemp extraction methods depends on production scale, with CO2 extraction favored for large-scale operations and ethanol extraction often used for smaller batches due to budget constraints.

Scalability for Industrial Hemp Processing

CO2 extraction offers higher scalability for industrial hemp processing due to its precise control over temperature and pressure, enabling continuous operation and consistent yield. Ethanol extraction, while simpler and cheaper initially, faces scalability challenges related to solvent recovery and potential degradation of cannabinoids during large-scale operations. Industrial manufacturers often prefer CO2 extraction for volume consistency and regulatory compliance in high-capacity hemp processing facilities.

Suitability for Different Hemp Products

CO2 extraction is highly suitable for producing high-purity hemp extracts such as CBD oils, tinctures, and vape concentrates due to its ability to precisely target cannabinoids and terpenes without solvent residues. Ethanol extraction excels in creating full-spectrum hemp products, including edibles and topicals, as it effectively extracts a wider range of compounds like chlorophyll and waxes, which can enhance product complexity. The choice between CO2 and ethanol extraction methods depends on the desired hemp product's cannabinoid profile, purity requirements, and sensory attributes.

Choosing the Right Extraction Method for Your Needs

CO2 extraction offers a clean, solvent-free method ideal for preserving hemp's delicate cannabinoids and terpenes, resulting in high-purity extracts with minimal degradation. Ethanol extraction, while efficient and cost-effective, can extract chlorophyll and other impurities, requiring additional purification steps to achieve clarity. Selecting the right method depends on factors like desired product quality, scale of production, and budget, with CO2 favored for premium, full-spectrum products and ethanol suited for larger-scale, rapid extraction.

CO₂ extraction vs ethanol extraction Infographic

materialdif.com

materialdif.com