Hemp-based packaging offers superior biodegradability and durability compared to traditional cardboard, making it an eco-friendly alternative for sustainable packaging solutions. The natural antimicrobial properties of hemp help extend product shelf life, while its lower water usage during production reduces environmental impact. Hemp packaging also provides enhanced strength and flexibility, ensuring better protection for goods during transportation and storage.

Table of Comparison

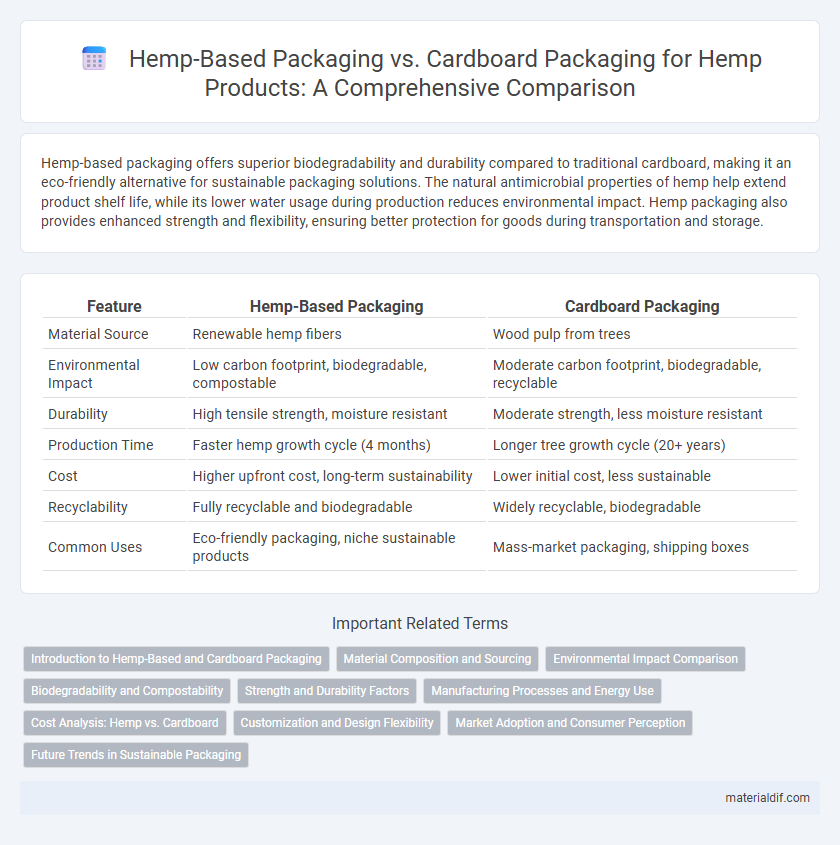

| Feature | Hemp-Based Packaging | Cardboard Packaging |

|---|---|---|

| Material Source | Renewable hemp fibers | Wood pulp from trees |

| Environmental Impact | Low carbon footprint, biodegradable, compostable | Moderate carbon footprint, biodegradable, recyclable |

| Durability | High tensile strength, moisture resistant | Moderate strength, less moisture resistant |

| Production Time | Faster hemp growth cycle (4 months) | Longer tree growth cycle (20+ years) |

| Cost | Higher upfront cost, long-term sustainability | Lower initial cost, less sustainable |

| Recyclability | Fully recyclable and biodegradable | Widely recyclable, biodegradable |

| Common Uses | Eco-friendly packaging, niche sustainable products | Mass-market packaging, shipping boxes |

Introduction to Hemp-Based and Cardboard Packaging

Hemp-based packaging offers a sustainable alternative to traditional cardboard, utilizing fibers from the hemp plant known for their durability and biodegradability. Cardboard packaging, primarily made from wood pulp, is widely used but often less eco-friendly due to deforestation and higher energy consumption in production. Hemp packaging boasts faster growth cycles and lower environmental impact, making it a compelling choice in the shift towards green packaging solutions.

Material Composition and Sourcing

Hemp-based packaging is derived from the fibrous stalks of the Cannabis sativa plant, offering a sustainable and renewable material composition rich in cellulose fibers that provide durability and biodegradability. In contrast, cardboard packaging primarily consists of wood pulp sourced from trees, contributing to deforestation concerns and requiring intensive water and chemical processing. The sourcing of hemp fibers involves faster crop growth cycles and lower pesticide use, making hemp a more environmentally friendly option compared to traditional cardboard made from virgin or recycled wood fibers.

Environmental Impact Comparison

Hemp-based packaging significantly reduces environmental impact compared to traditional cardboard by requiring fewer pesticides, less water, and less land for cultivation, which contributes to lower greenhouse gas emissions. The biodegradability and recyclability of hemp fibers enhance waste management efficiency, reducing landfill burden and promoting circular economy principles. Hemp's rapid growth cycle allows for more sustainable production cycles, making it a superior eco-friendly alternative for packaging industries.

Biodegradability and Compostability

Hemp-based packaging outperforms traditional cardboard packaging in biodegradability, breaking down within 3 to 6 months compared to cardboard's 2 to 5 months, due to its natural fiber composition and resistance to chemical treatments. Compostability of hemp packaging is significantly higher, as it decomposes into nutrient-rich organic matter without leaving harmful residues, supporting soil health and reducing landfill waste. Industrial testing confirms hemp packaging's superior environmental benefits, making it a sustainable alternative to conventional cardboard in eco-friendly packaging solutions.

Strength and Durability Factors

Hemp-based packaging offers superior strength and durability compared to traditional cardboard, thanks to its long, fibrous stalks that provide enhanced tensile resistance and moisture tolerance. The natural lignin content in hemp fibers contributes to greater rigidity and resistance to wear, reducing the likelihood of crushing or deformation during transport. These properties make hemp packaging an eco-friendly, sustainable alternative that maintains structural integrity under demanding conditions.

Manufacturing Processes and Energy Use

Hemp-based packaging utilizes fibers from the hemp plant, which require less water and fewer pesticides during cultivation compared to traditional wood sources for cardboard, resulting in a lower environmental impact during raw material production. The manufacturing process for hemp packaging involves fewer chemical treatments and less energy-intensive pulping methods, reducing overall energy consumption compared to the kraft process used in cardboard production. Energy efficiency during hemp packaging manufacturing contributes to decreased greenhouse gas emissions, positioning hemp as a sustainable alternative to conventional cardboard packaging.

Cost Analysis: Hemp vs. Cardboard

Hemp-based packaging typically incurs higher initial production costs compared to traditional cardboard due to limited supply chains and more complex processing requirements. However, hemp materials offer superior durability and biodegradability, potentially reducing long-term environmental and disposal expenses. Economies of scale and advancements in hemp processing technology are expected to decrease costs, making hemp packaging increasingly competitive with cardboard in sustainable packaging markets.

Customization and Design Flexibility

Hemp-based packaging offers superior customization options and design flexibility compared to traditional cardboard, allowing for more intricate textures, unique shapes, and eco-friendly printing techniques. Its natural fibers provide a durable yet lightweight structure that can be easily molded and enhanced for brand differentiation. This adaptability makes hemp packaging ideal for businesses seeking sustainable solutions without compromising aesthetic appeal or functional versatility.

Market Adoption and Consumer Perception

Hemp-based packaging is gaining rapid market adoption due to its sustainability, biodegradability, and lower environmental impact compared to traditional cardboard packaging. Consumers increasingly prefer hemp packaging for its natural, eco-friendly attributes and durability, driving demand in industries such as food, cosmetics, and retail. Market research indicates a growing willingness to pay a premium for hemp-based solutions, reflecting a shift toward green consumer behavior and corporate sustainability goals.

Future Trends in Sustainable Packaging

Hemp-based packaging outperforms traditional cardboard by offering superior biodegradability and lower carbon emissions throughout its lifecycle, aligning with increasing regulatory demands for eco-friendly materials. Innovations in hemp fiber processing enhance durability and water resistance, positioning hemp as a scalable alternative in the growing sustainable packaging market projected to reach $410 billion by 2030. Major corporations are investing in hemp packaging research to meet consumer preferences for renewable, compostable options, signaling a significant shift toward industrial hemp as a leading material in circular economy frameworks.

Hemp-based packaging vs Cardboard packaging Infographic

materialdif.com

materialdif.com