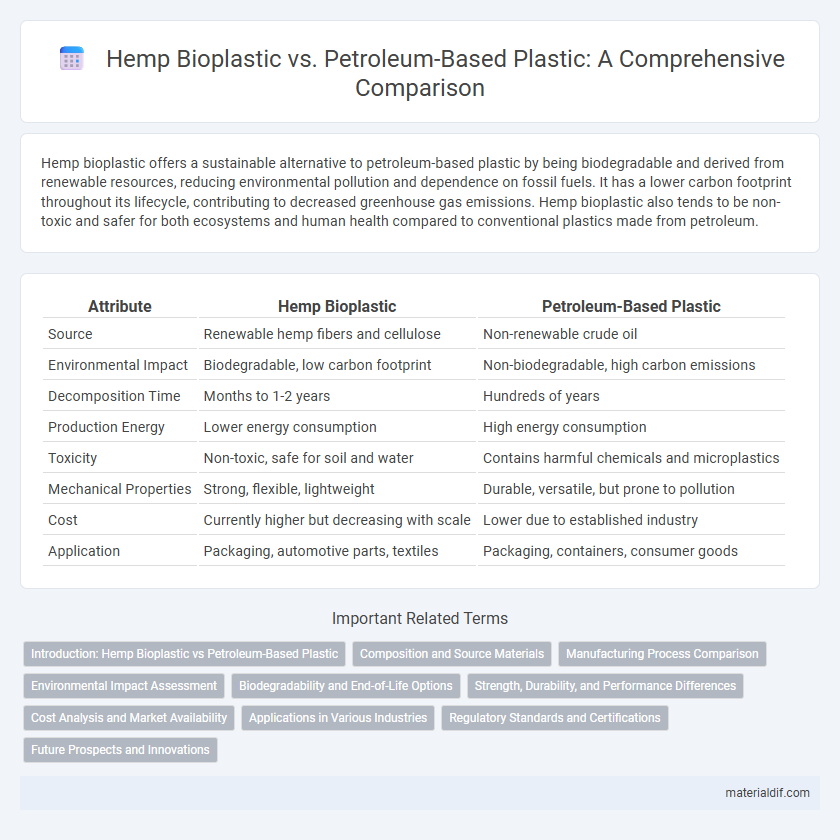

Hemp bioplastic offers a sustainable alternative to petroleum-based plastic by being biodegradable and derived from renewable resources, reducing environmental pollution and dependence on fossil fuels. It has a lower carbon footprint throughout its lifecycle, contributing to decreased greenhouse gas emissions. Hemp bioplastic also tends to be non-toxic and safer for both ecosystems and human health compared to conventional plastics made from petroleum.

Table of Comparison

| Attribute | Hemp Bioplastic | Petroleum-Based Plastic |

|---|---|---|

| Source | Renewable hemp fibers and cellulose | Non-renewable crude oil |

| Environmental Impact | Biodegradable, low carbon footprint | Non-biodegradable, high carbon emissions |

| Decomposition Time | Months to 1-2 years | Hundreds of years |

| Production Energy | Lower energy consumption | High energy consumption |

| Toxicity | Non-toxic, safe for soil and water | Contains harmful chemicals and microplastics |

| Mechanical Properties | Strong, flexible, lightweight | Durable, versatile, but prone to pollution |

| Cost | Currently higher but decreasing with scale | Lower due to established industry |

| Application | Packaging, automotive parts, textiles | Packaging, containers, consumer goods |

Introduction: Hemp Bioplastic vs Petroleum-Based Plastic

Hemp bioplastic offers a sustainable alternative to petroleum-based plastic by utilizing renewable hemp fibers that reduce carbon emissions and enhance biodegradability. Unlike conventional plastics derived from fossil fuels, hemp bioplastics decompose faster, minimizing environmental pollution and landfill accumulation. The growing demand for eco-friendly materials accelerates the adoption of hemp bioplastics in packaging, automotive parts, and consumer products.

Composition and Source Materials

Hemp bioplastic is derived from the cellulose fibers and oils extracted from hemp plants, offering a renewable and biodegradable alternative to petroleum-based plastics, which are synthesized from fossil fuels such as crude oil and natural gas. The composition of hemp bioplastics typically includes natural polymers like cellulose, lignin, and hemicellulose, contributing to their strength and eco-friendly degradation properties, whereas petroleum-based plastics predominantly consist of synthetic polymers such as polyethylene, polypropylene, and polystyrene. The sustainable sourcing of hemp, which requires less water and pesticides compared to conventional crops, contrasts sharply with the finite and environmentally detrimental extraction processes of petroleum used in traditional plastic production.

Manufacturing Process Comparison

Hemp bioplastic manufacturing involves processing hemp fibers into biodegradable polymers through enzymatic or chemical methods, resulting in a sustainable material with a lower carbon footprint. Petroleum-based plastic production relies on refining crude oil followed by polymerization processes such as extrusion or injection molding, which emit higher levels of greenhouse gases. The renewable nature of hemp raw materials and energy-efficient processing makes hemp bioplastics a more environmentally friendly alternative compared to conventional petroleum-based plastics.

Environmental Impact Assessment

Hemp bioplastic significantly reduces carbon emissions compared to petroleum-based plastic, as it is derived from rapidly renewable biomass that absorbs CO2 during growth. Lifecycle analysis reveals that hemp bioplastics generate less toxic waste and lower energy consumption during production, minimizing environmental pollution. Its biodegradability also prevents long-term soil and marine contamination linked to traditional plastics, enhancing sustainable waste management practices.

Biodegradability and End-of-Life Options

Hemp bioplastic offers superior biodegradability compared to petroleum-based plastic, breaking down naturally within months under composting conditions rather than persisting for centuries in landfills. End-of-life options for hemp bioplastic include industrial composting and anaerobic digestion, enabling conversion into organic matter or biogas, whereas petroleum plastics primarily rely on recycling or landfill disposal with limited degradation. This sustainable lifecycle significantly reduces environmental impact and supports circular economy goals by minimizing plastic pollution and landfill accumulation.

Strength, Durability, and Performance Differences

Hemp bioplastic exhibits superior tensile strength and flexibility compared to many petroleum-based plastics, resulting from its natural cellulose fiber composition. Its enhanced durability resists cracking and degradation under stress, making it ideal for applications requiring long-lasting materials. Performance-wise, hemp bioplastics offer better biodegradability and resistance to UV radiation, addressing environmental and functional limitations common in petroleum-based plastics.

Cost Analysis and Market Availability

Hemp bioplastic offers a competitive edge in cost analysis due to lower raw material expenses and reduced environmental compliance fees compared to petroleum-based plastics. Market availability of hemp bioplastics is expanding rapidly, driven by increasing consumer demand for sustainable alternatives and supportive regulatory policies encouraging biobased products. While petroleum-based plastics dominate global production with well-established supply chains, hemp bioplastics are gaining traction in niche markets, highlighting their potential for scalable commercialization.

Applications in Various Industries

Hemp bioplastic is increasingly utilized in automotive, packaging, and consumer goods industries due to its biodegradability and lower carbon footprint compared to petroleum-based plastics. Its application in the automotive sector includes interior panels and insulation, offering lightweight and durable alternatives that enhance fuel efficiency. In packaging, hemp bioplastic provides sustainable solutions for food containers and bags, reducing plastic pollution and supporting circular economy initiatives.

Regulatory Standards and Certifications

Hemp bioplastic meets emerging regulatory standards such as ASTM D7611 for biodegradable plastics and EN 13432 for compostability, ensuring compliance with eco-friendly production benchmarks. Petroleum-based plastics are subject to stricter regulations on chemical additives and recyclability, with agencies like the EPA enforcing limits on hazardous substances. Hemp bioplastics often achieve certifications like USDA BioPreferred and OK Compost, highlighting their sustainable lifecycle and reduced environmental impact compared to conventional petrochemical plastics.

Future Prospects and Innovations

Hemp bioplastic offers a sustainable alternative to petroleum-based plastic due to its biodegradability, lower carbon footprint, and renewable sourcing from fast-growing hemp plants. Innovations in hemp bioplastic focus on enhancing material strength, flexibility, and water resistance to compete with synthetic plastics in packaging, automotive, and consumer goods industries. Future prospects include scaling production through agricultural advancements and integrated biorefinery processes that improve cost-efficiency and lifecycle performance in circular economy models.

hemp bioplastic vs petroleum-based plastic Infographic

materialdif.com

materialdif.com