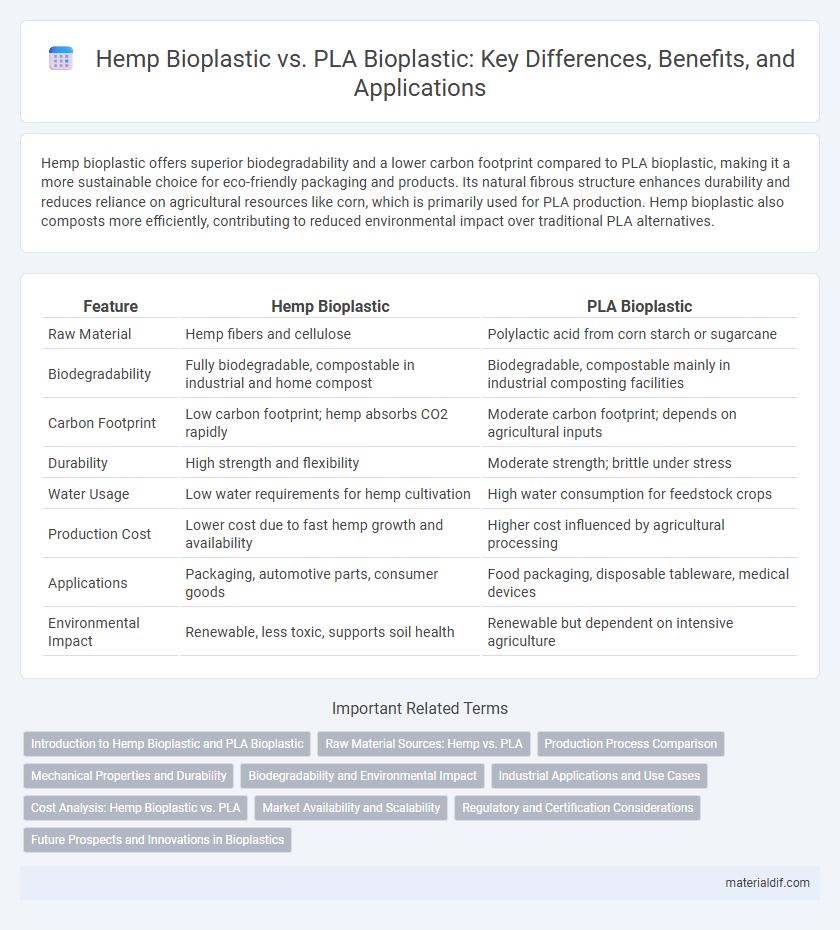

Hemp bioplastic offers superior biodegradability and a lower carbon footprint compared to PLA bioplastic, making it a more sustainable choice for eco-friendly packaging and products. Its natural fibrous structure enhances durability and reduces reliance on agricultural resources like corn, which is primarily used for PLA production. Hemp bioplastic also composts more efficiently, contributing to reduced environmental impact over traditional PLA alternatives.

Table of Comparison

| Feature | Hemp Bioplastic | PLA Bioplastic |

|---|---|---|

| Raw Material | Hemp fibers and cellulose | Polylactic acid from corn starch or sugarcane |

| Biodegradability | Fully biodegradable, compostable in industrial and home compost | Biodegradable, compostable mainly in industrial composting facilities |

| Carbon Footprint | Low carbon footprint; hemp absorbs CO2 rapidly | Moderate carbon footprint; depends on agricultural inputs |

| Durability | High strength and flexibility | Moderate strength; brittle under stress |

| Water Usage | Low water requirements for hemp cultivation | High water consumption for feedstock crops |

| Production Cost | Lower cost due to fast hemp growth and availability | Higher cost influenced by agricultural processing |

| Applications | Packaging, automotive parts, consumer goods | Food packaging, disposable tableware, medical devices |

| Environmental Impact | Renewable, less toxic, supports soil health | Renewable but dependent on intensive agriculture |

Introduction to Hemp Bioplastic and PLA Bioplastic

Hemp bioplastic is a sustainable material derived from the fibers and cellulose of the hemp plant, offering biodegradability and reduced carbon footprint compared to traditional plastics. PLA (polylactic acid) bioplastic is produced from fermented plant starch, commonly corn, and is known for its compostability and greenhouse gas reduction during manufacturing. Both materials provide eco-friendly alternatives to petroleum-based plastics, with hemp bioplastic emphasizing natural fiber reinforcement and PLA focusing on renewable carbohydrate sources.

Raw Material Sources: Hemp vs. PLA

Hemp bioplastic is derived from the fibrous stalks of industrial hemp plants, offering a renewable and sustainable raw material with low agricultural input requirements. PLA bioplastic is produced from fermented plant starches, primarily corn, which demands significant water and fertilizer use, raising concerns about food competition and environmental impact. The hemp source provides a more eco-friendly raw material with rapid growth cycles and soil remediation benefits compared to the more resource-intensive PLA feedstocks.

Production Process Comparison

Hemp bioplastic production involves extracting cellulose fibers from hemp biomass, followed by chemical or enzymatic treatments to convert fibers into biopolymer precursors, which are then processed into bioplastic materials. PLA bioplastic production relies on fermenting sugars derived from corn or sugarcane into lactic acid, which undergoes polymerization to form polylactic acid resin. The hemp bioplastic process emphasizes renewable fiber extraction with lower agricultural input, while PLA relies heavily on carbohydrate fermentation and feedstock availability.

Mechanical Properties and Durability

Hemp bioplastic exhibits superior mechanical properties compared to PLA bioplastic, including higher tensile strength and enhanced impact resistance due to the strong cellulose fibers in hemp. The durability of hemp bioplastic surpasses PLA in terms of thermal stability and biodegradation rate, making it more suitable for applications requiring longer lifespan and exposure to varying environmental conditions. Hemp bioplastic's resistance to moisture and UV degradation further enhances its performance over PLA in demanding industrial uses.

Biodegradability and Environmental Impact

Hemp bioplastic demonstrates superior biodegradability compared to PLA bioplastic, breaking down more quickly in natural environments without releasing harmful residues. The cultivation of hemp requires fewer pesticides and less water, contributing to a lower environmental footprint during raw material production. In contrast, PLA bioplastic, derived from corn starch, often involves intensive agriculture and may require industrial composting facilities for effective degradation, limiting its ecological benefits.

Industrial Applications and Use Cases

Hemp bioplastic offers superior biodegradability, high tensile strength, and resistance to UV radiation, making it ideal for automotive parts, packaging, and durable consumer goods in industrial applications. PLA bioplastic, derived from cornstarch, excels in food packaging, disposable cutlery, and 3D printing due to its compostability and ease of production but lacks the mechanical durability required for long-term industrial use. Industries increasingly favor hemp bioplastics for sustainable manufacturing processes where material strength and environmental impact are critical factors.

Cost Analysis: Hemp Bioplastic vs. PLA

Hemp bioplastic generally offers a cost advantage over PLA bioplastic due to lower raw material expenses and reduced agricultural input costs, as hemp requires less water and pesticides for cultivation. PLA bioplastic, derived from corn starch, faces price volatility linked to food crop markets and intensive farming practices, increasing production costs. Economies of scale in PLA manufacturing currently result in more established supply chains, but rising demand for sustainable alternatives is narrowing the cost gap favoring hemp bioplastic.

Market Availability and Scalability

Hemp bioplastic offers enhanced market availability due to its rapid growth cycle and abundant raw material supply compared to PLA bioplastic, which relies heavily on corn starch and faces limitations from agricultural land use. Scalability of hemp bioplastics benefits from existing hemp farming infrastructure and lower environmental impact, allowing for more sustainable mass production. In contrast, PLA bioplastic scalability is constrained by feedstock availability and fluctuating commodity prices, affecting consistent supply chain expansion.

Regulatory and Certification Considerations

Hemp bioplastic and PLA bioplastic differ significantly in regulatory and certification frameworks due to their raw material origins and biodegradability profiles. Hemp bioplastics often face complex regulations related to hemp cultivation and THC content compliance, while PLA bioplastics benefit from well-established certifications such as ASTM D6400 for compostability and FDA approval for food contact. Understanding these distinctions is critical for manufacturers aiming to meet international environmental standards and market access requirements.

Future Prospects and Innovations in Bioplastics

Hemp bioplastic offers promising future prospects due to its rapid growth, high cellulose content, and carbon sequestration benefits, making it a sustainable alternative to PLA bioplastic derived from corn starch. Innovations in hemp-based composites are enhancing biodegradability and mechanical strength, positioning hemp bioplastics as a viable choice for packaging, automotive, and consumer goods industries. Advancements in bioengineering and processing techniques continue to reduce production costs and improve performance, signaling a significant shift towards environmentally-friendly materials in the global bioplastics market.

Hemp Bioplastic vs PLA Bioplastic Infographic

materialdif.com

materialdif.com