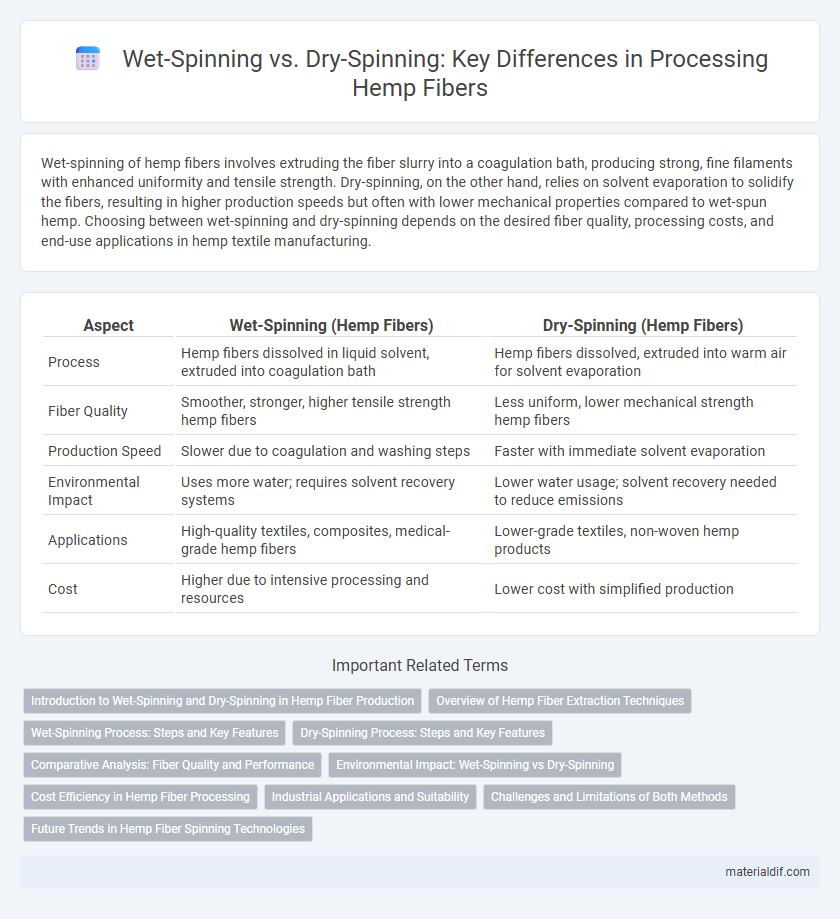

Wet-spinning of hemp fibers involves extruding the fiber slurry into a coagulation bath, producing strong, fine filaments with enhanced uniformity and tensile strength. Dry-spinning, on the other hand, relies on solvent evaporation to solidify the fibers, resulting in higher production speeds but often with lower mechanical properties compared to wet-spun hemp. Choosing between wet-spinning and dry-spinning depends on the desired fiber quality, processing costs, and end-use applications in hemp textile manufacturing.

Table of Comparison

| Aspect | Wet-Spinning (Hemp Fibers) | Dry-Spinning (Hemp Fibers) |

|---|---|---|

| Process | Hemp fibers dissolved in liquid solvent, extruded into coagulation bath | Hemp fibers dissolved, extruded into warm air for solvent evaporation |

| Fiber Quality | Smoother, stronger, higher tensile strength hemp fibers | Less uniform, lower mechanical strength hemp fibers |

| Production Speed | Slower due to coagulation and washing steps | Faster with immediate solvent evaporation |

| Environmental Impact | Uses more water; requires solvent recovery systems | Lower water usage; solvent recovery needed to reduce emissions |

| Applications | High-quality textiles, composites, medical-grade hemp fibers | Lower-grade textiles, non-woven hemp products |

| Cost | Higher due to intensive processing and resources | Lower cost with simplified production |

Introduction to Wet-Spinning and Dry-Spinning in Hemp Fiber Production

Wet-spinning of hemp fibers involves dissolving cellulose in a chemical solvent before extruding the solution into a coagulation bath, allowing fine, continuous filaments crucial for high-strength textile applications. Dry-spinning contrasts by evaporating a solvent-filled cellulose solution through warm air, producing fibers with different mechanical properties and surface characteristics suited for varied end uses. These spinning methods directly impact the fiber's quality, durability, and application potential in sustainable hemp textile manufacturing.

Overview of Hemp Fiber Extraction Techniques

Wet-spinning of hemp fibers involves immersing the raw fibers in a liquid bath to facilitate stronger, finer yarns by aligning cellulose molecules, resulting in superior tensile strength and softness ideal for high-quality textiles. Dry-spinning extracts fibers through mechanical means without water, producing coarser, stiffer yarns suited for industrial applications like ropes and composites. Both techniques are integral to hemp fiber extraction, each optimized for specific end-use properties based on fiber morphology and processing conditions.

Wet-Spinning Process: Steps and Key Features

The wet-spinning process for hemp fibers involves dissolving hemp cellulose in a solvent to create a viscous solution, which is extruded through spinnerets into a coagulation bath where fibers solidify. Key features include high fiber strength, uniform filament formation, and superior fineness compared to dry-spinning, making it ideal for producing regenerated hemp fibers for textiles. The process requires precise control of temperature and chemical concentration to ensure optimal fiber properties and minimize environmental impact.

Dry-Spinning Process: Steps and Key Features

Dry-spinning of hemp fibers involves dissolving the cellulose extracted from hemp stalks in a suitable solvent, followed by extruding the solution through spinnerets into a heated chamber where the solvent evaporates, leaving solid fibers. Key steps include preparation of the hemp cellulose solution, extrusion, solvent evaporation, and fiber collection, resulting in continuous, fine, and uniform fibers suitable for textile applications. This process offers advantages such as controlled fiber diameter, enhanced surface smoothness, and improved mechanical properties compared to wet-spinning methods.

Comparative Analysis: Fiber Quality and Performance

Wet-spinning of hemp fibers results in higher tensile strength and improved fiber uniformity compared to dry-spinning, due to the fiber alignment achieved in the aqueous medium. Dry-spinning tends to produce fibers with greater porosity and lower mechanical performance but allows faster processing and lower energy consumption. The choice between wet-spinning and dry-spinning directly influences the durability, flexibility, and end-use applications of hemp textile products.

Environmental Impact: Wet-Spinning vs Dry-Spinning

Wet-spinning hemp fibers consumes significantly more water and generates wastewater requiring treatment, increasing environmental strain compared to dry-spinning's lower water usage and reduced chemical runoff. Dry-spinning's energy consumption is generally higher due to solvent recovery processes, but it produces fewer pollutants overall, contributing to a smaller ecological footprint. Choosing dry-spinning for hemp fiber processing supports sustainable manufacturing by minimizing water pollution and conserving vital water resources.

Cost Efficiency in Hemp Fiber Processing

Wet-spinning of hemp fibers involves higher water and energy consumption, resulting in increased operational costs compared to dry-spinning. Dry-spinning offers greater cost efficiency by reducing processing time and minimizing resource use, making it preferable for large-scale, sustainable hemp fiber production. Choosing dry-spinning enhances profitability by lowering labor and maintenance expenses while maintaining fiber quality.

Industrial Applications and Suitability

Wet-spinning of hemp fibers produces finer, stronger yarns ideal for high-performance textiles in automotive and medical industries, while dry-spinning yields coarser fibers suited for durable fabrics in construction and upholstery. The wet-spinning process maintains fiber integrity and ensures superior tensile strength, making it preferable for applications requiring enhanced durability and flexibility. Dry-spinning is more cost-effective and faster, suitable for large-scale production of hemp-based geotextiles and insulation materials where less fiber refinement is acceptable.

Challenges and Limitations of Both Methods

Wet-spinning of hemp fibers faces challenges such as high water consumption and complex drying processes, which increase operational costs and environmental impact. Dry-spinning, while more energy-efficient, struggles with inconsistent fiber quality and limited scalability due to fiber brittleness during processing. Both methods confront limitations in achieving uniform fiber properties and cost-effective large-scale production essential for industrial hemp applications.

Future Trends in Hemp Fiber Spinning Technologies

Future trends in hemp fiber spinning technologies emphasize the advancement of wet-spinning methods due to their ability to produce finer, stronger fibers with enhanced uniformity suitable for high-performance textiles. Innovations in eco-friendly wet-spinning processes aim to reduce water consumption and chemical usage, aligning with sustainable production goals. Meanwhile, dry-spinning techniques are being optimized for energy efficiency and scalability, supporting mass-market applications while maintaining fiber quality standards.

Wet-spinning vs Dry-spinning (Hemp fibers) Infographic

materialdif.com

materialdif.com