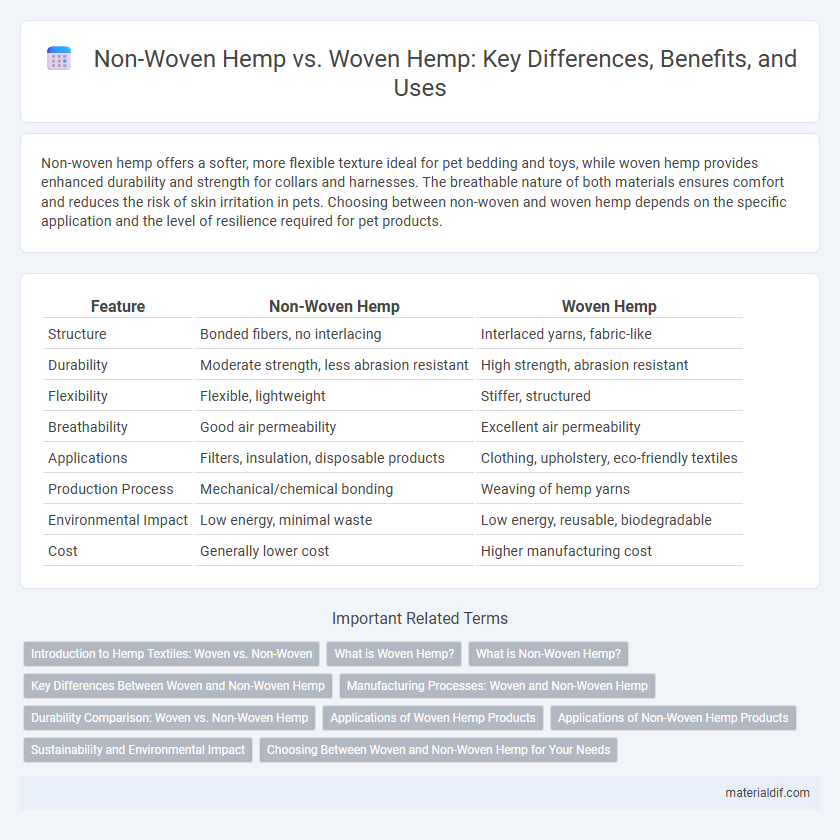

Non-woven hemp offers a softer, more flexible texture ideal for pet bedding and toys, while woven hemp provides enhanced durability and strength for collars and harnesses. The breathable nature of both materials ensures comfort and reduces the risk of skin irritation in pets. Choosing between non-woven and woven hemp depends on the specific application and the level of resilience required for pet products.

Table of Comparison

| Feature | Non-Woven Hemp | Woven Hemp |

|---|---|---|

| Structure | Bonded fibers, no interlacing | Interlaced yarns, fabric-like |

| Durability | Moderate strength, less abrasion resistant | High strength, abrasion resistant |

| Flexibility | Flexible, lightweight | Stiffer, structured |

| Breathability | Good air permeability | Excellent air permeability |

| Applications | Filters, insulation, disposable products | Clothing, upholstery, eco-friendly textiles |

| Production Process | Mechanical/chemical bonding | Weaving of hemp yarns |

| Environmental Impact | Low energy, minimal waste | Low energy, reusable, biodegradable |

| Cost | Generally lower cost | Higher manufacturing cost |

Introduction to Hemp Textiles: Woven vs. Non-Woven

Non-woven hemp textiles are created by bonding hemp fibers using heat, chemicals, or pressure, resulting in a fabric that is lightweight and highly absorbent, ideal for applications like insulation and filters. Woven hemp textiles involve interlacing warp and weft fibers on a loom, producing durable and breathable fabrics commonly used in clothing, upholstery, and eco-friendly fashion. The choice between non-woven and woven hemp fabrics depends on the desired strength, texture, and use-case, with woven hemp offering superior tensile strength and non-woven hemp providing enhanced flexibility and softness.

What is Woven Hemp?

Woven hemp is a fabric made by interlacing hemp fibers in a crisscross pattern, creating a strong and durable textile ideal for clothing, upholstery, and industrial applications. Unlike non-woven hemp, which is bonded using adhesives or mechanical processes without weaving, woven hemp offers superior tensile strength and breathability due to its structured weave. The natural properties of woven hemp, such as moisture-wicking and antimicrobial characteristics, make it valuable for sustainable and eco-friendly products.

What is Non-Woven Hemp?

Non-woven hemp is a fabric made by bonding hemp fibers through mechanical, chemical, or thermal methods, without the traditional weaving or knitting process. This type of hemp material offers enhanced durability, breathability, and flexibility, making it ideal for applications like upholstery, insulation, and geotextiles. Unlike woven hemp, non-woven hemp allows for faster production and can be engineered for specific performance characteristics.

Key Differences Between Woven and Non-Woven Hemp

Woven hemp fabrics consist of interlaced threads forming a structured, durable material ideal for textiles requiring strength and flexibility, while non-woven hemp is made by bonding fibers together through mechanical, chemical, or thermal processes, resulting in a softer, more absorbent, and less durable fabric. Key differences include breathability, texture, and mechanical properties, with woven hemp offering greater tensile strength and longevity compared to the looser, more porous structure of non-woven hemp, which excels in filtration, insulation, and disposable products. Applications vary accordingly: woven hemp suits apparel and upholstery, whereas non-woven hemp is preferred for geotextiles, cleaning pads, and biodegradable composites.

Manufacturing Processes: Woven and Non-Woven Hemp

Woven hemp fabric is produced by interlacing warp and weft yarns on looms, resulting in a durable and flexible textile with a distinct grid-like pattern. Non-woven hemp is manufactured by bonding or felting hemp fibers together using mechanical, chemical, or thermal processes, creating a dense and uniform material without yarn formation. The manufacturing of woven hemp allows for greater tensile strength and breathability, while non-woven hemp offers advantages in uniformity and cost-effective production for insulation, geotextiles, and composites.

Durability Comparison: Woven vs. Non-Woven Hemp

Woven hemp fabric boasts greater durability due to its interlaced yarn structure, providing enhanced strength and resistance to wear compared to non-woven hemp, which is made by bonding fibers together without weaving. Non-woven hemp excels in flexibility and softness but tends to have lower tensile strength, making it less suitable for heavy-duty applications. The durability of woven hemp makes it ideal for industrial uses such as upholstery, while non-woven hemp is often preferred in products requiring breathability and lightweight characteristics.

Applications of Woven Hemp Products

Woven hemp products are widely used in the textile industry for apparel, upholstery, and industrial fabrics due to their strength and durability. Their tightly interlaced fibers provide enhanced abrasion resistance and structural integrity, making them ideal for heavy-duty applications such as geotextiles and eco-friendly packaging. These characteristics enable woven hemp to support sustainable construction materials and automotive composites, expanding its versatility beyond traditional fabric uses.

Applications of Non-Woven Hemp Products

Non-woven hemp products are widely used in automotive interiors, geotextiles, and home insulation due to their lightweight, durability, and excellent thermal properties. These materials provide superior sound absorption and moisture resistance, making them ideal for acoustic panels and mattress padding. Non-woven hemp also plays a critical role in biodegradable packaging and medical textiles, offering sustainable alternatives to synthetic fibers.

Sustainability and Environmental Impact

Non-woven hemp fabrics reduce water consumption and energy use during production compared to woven hemp, making them more sustainable for eco-friendly applications. The manufacturing of woven hemp involves intensive mechanical processing that increases carbon emissions and waste generation. Non-woven hemp's biodegradability and lower resource requirements contribute significantly to reducing the environmental footprint of hemp-based textiles.

Choosing Between Woven and Non-Woven Hemp for Your Needs

Non-woven hemp fabric offers enhanced flexibility and superior insulation properties, making it ideal for applications like upholstery, filters, and geotextiles where breathability and permeability are prioritized. Woven hemp, characterized by its durability and strength, suits fashion apparel, bags, and industrial textiles requiring high tensile strength and resistance to wear. Selecting between woven and non-woven hemp depends on balancing factors like texture, strength, breathability, and intended use to achieve optimal performance in your specific project.

Non-woven hemp vs Woven hemp Infographic

materialdif.com

materialdif.com