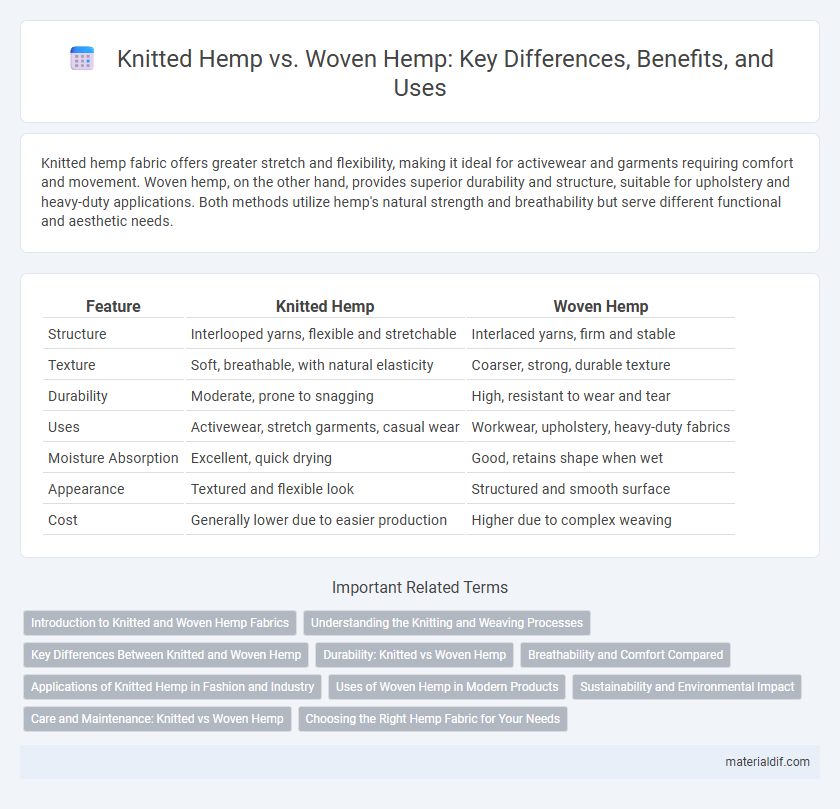

Knitted hemp fabric offers greater stretch and flexibility, making it ideal for activewear and garments requiring comfort and movement. Woven hemp, on the other hand, provides superior durability and structure, suitable for upholstery and heavy-duty applications. Both methods utilize hemp's natural strength and breathability but serve different functional and aesthetic needs.

Table of Comparison

| Feature | Knitted Hemp | Woven Hemp |

|---|---|---|

| Structure | Interlooped yarns, flexible and stretchable | Interlaced yarns, firm and stable |

| Texture | Soft, breathable, with natural elasticity | Coarser, strong, durable texture |

| Durability | Moderate, prone to snagging | High, resistant to wear and tear |

| Uses | Activewear, stretch garments, casual wear | Workwear, upholstery, heavy-duty fabrics |

| Moisture Absorption | Excellent, quick drying | Good, retains shape when wet |

| Appearance | Textured and flexible look | Structured and smooth surface |

| Cost | Generally lower due to easier production | Higher due to complex weaving |

Introduction to Knitted and Woven Hemp Fabrics

Knitted hemp fabrics are created by interlocking loops of hemp yarn, resulting in a stretchy, breathable material ideal for activewear and casual garments. Woven hemp fabrics are made by interlacing hemp threads at right angles, producing a durable, structured fabric commonly used in upholstery and heavy-duty clothing. Both types showcase hemp's natural strength and sustainability but differ in texture, flexibility, and application.

Understanding the Knitting and Weaving Processes

Knitted hemp fabric is created by interlocking yarn loops, resulting in a flexible, stretchy material ideal for garments requiring elasticity and comfort. Woven hemp fabric involves interlacing warp and weft yarns at right angles, producing a durable, structured textile suited for heavy-duty applications like upholstery or bags. Understanding these processes highlights how knitting enhances breathability and flexibility, while weaving emphasizes strength and dimensional stability in hemp textiles.

Key Differences Between Knitted and Woven Hemp

Knitted hemp fabric is created through interlocking loops of yarn, offering superior stretchability and elasticity compared to woven hemp, which is made by interlacing yarns at right angles to produce a stronger, more rigid textile. Woven hemp excels in durability and breathability, making it suitable for heavy-duty applications like upholstery and outerwear, whereas knitted hemp provides enhanced comfort and flexibility for garments such as t-shirts and activewear. The structural differences impact the texture and drape, with woven hemp exhibiting a smoother, crisper finish and knitted hemp presenting a softer, more pliable hand feel.

Durability: Knitted vs Woven Hemp

Woven hemp fabric offers superior durability due to its tight interlacing of fibers, making it highly resistant to wear and tear compared to knitted hemp. Knitted hemp, while more flexible and comfortable, is prone to stretching and may develop holes faster under heavy use. For applications requiring long-lasting strength and abrasion resistance, woven hemp is the preferred choice.

Breathability and Comfort Compared

Knitted hemp fabric offers superior breathability and flexibility due to its looped yarn construction, allowing better air circulation and stretch, enhancing overall comfort. Woven hemp, with its tight interlaced fibers, provides durability and structure but tends to be less breathable and flexible, making it less comfortable in warmer climates. Choosing between knitted and woven hemp depends on the desired balance of comfort and durability for specific apparel or textile uses.

Applications of Knitted Hemp in Fashion and Industry

Knitted hemp fabric offers superior stretch and flexibility compared to woven hemp, making it ideal for fashion items like activewear, casual clothing, and accessories that require comfort and movement. Its breathable and moisture-wicking properties enhance its popularity in performance wear and sustainable fashion lines. In industrial applications, knitted hemp is used for durable, eco-friendly textiles such as upholstery, industrial filters, and geotextiles, benefiting from its strength and biodegradability.

Uses of Woven Hemp in Modern Products

Woven hemp fabric is prized for its durability and strength, making it ideal for products that require long-lasting wear, such as upholstery, industrial bags, and footwear. Its tight weave offers enhanced resistance to abrasion and tearing, favored in outdoor gear and eco-friendly fashion lines. Advanced textile technologies have expanded woven hemp's applications to include automotive interiors and sustainable home furnishings.

Sustainability and Environmental Impact

Knitted hemp fabric offers enhanced flexibility and breathability with minimal waste during production, contributing to sustainable textile manufacturing. Woven hemp, known for its durability and strength, typically requires more energy-intensive processes but provides longer-lasting material that reduces frequent replacement. Both methods utilize hemp's natural resilience and biodegradability, significantly lowering environmental impact compared to synthetic alternatives.

Care and Maintenance: Knitted vs Woven Hemp

Knitted hemp fabric requires more delicate care compared to woven hemp due to its stretchable and flexible structure, which can be prone to snagging and deformation. Woven hemp, with its tighter and more rigid weave, offers greater durability and resistance to wear during regular washing and maintenance. Both types benefit from gentle cold water washing and air drying to preserve the fiber strength and extend garment lifespan.

Choosing the Right Hemp Fabric for Your Needs

Knitted hemp fabric offers exceptional stretch and flexibility, making it ideal for activewear and garments requiring comfort and movement. Woven hemp fabric provides durability and a structured feel, perfect for upholstery, bags, and outerwear that demand strength and longevity. Selecting between knitted and woven hemp depends on the intended use, balancing elasticity with durability to meet your specific project requirements.

Knitted Hemp vs Woven Hemp Infographic

materialdif.com

materialdif.com