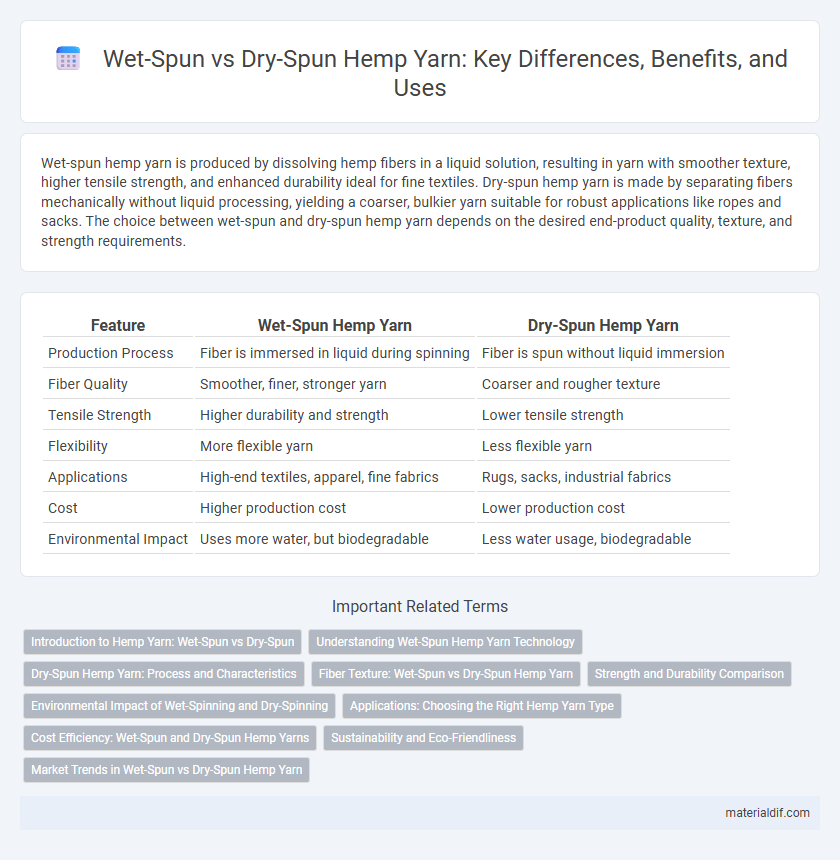

Wet-spun hemp yarn is produced by dissolving hemp fibers in a liquid solution, resulting in yarn with smoother texture, higher tensile strength, and enhanced durability ideal for fine textiles. Dry-spun hemp yarn is made by separating fibers mechanically without liquid processing, yielding a coarser, bulkier yarn suitable for robust applications like ropes and sacks. The choice between wet-spun and dry-spun hemp yarn depends on the desired end-product quality, texture, and strength requirements.

Table of Comparison

| Feature | Wet-Spun Hemp Yarn | Dry-Spun Hemp Yarn |

|---|---|---|

| Production Process | Fiber is immersed in liquid during spinning | Fiber is spun without liquid immersion |

| Fiber Quality | Smoother, finer, stronger yarn | Coarser and rougher texture |

| Tensile Strength | Higher durability and strength | Lower tensile strength |

| Flexibility | More flexible yarn | Less flexible yarn |

| Applications | High-end textiles, apparel, fine fabrics | Rugs, sacks, industrial fabrics |

| Cost | Higher production cost | Lower production cost |

| Environmental Impact | Uses more water, but biodegradable | Less water usage, biodegradable |

Introduction to Hemp Yarn: Wet-Spun vs Dry-Spun

Wet-spun hemp yarn undergoes a water-based fiber extraction process that yields smoother, finer threads ideal for high-quality textiles, while dry-spun hemp yarn is produced through mechanical decortication and spinning, resulting in coarser and stronger fibers suited for industrial uses. The wet-spinning technique enhances fiber alignment and removes lignin, improving softness and dye uptake, whereas dry-spinning preserves more of the plant's natural structure, offering greater durability and resistance. Choosing between wet-spun and dry-spun hemp yarn depends on the desired balance between texture, strength, and application in fashion or manufacturing sectors.

Understanding Wet-Spun Hemp Yarn Technology

Wet-spun hemp yarn technology involves immersing hemp fibers in a liquid solution during the spinning process, which enhances fiber alignment and produces a smoother, stronger yarn with superior tensile strength compared to dry-spun variants. This method retains more cellulose content and allows for finer fiber extraction, resulting in higher-quality hemp yarn ideal for textile applications demanding durability and comfort. Wet-spun hemp yarn demonstrates excellent moisture absorption and dye affinity, contributing to sustainable and eco-friendly fabric production.

Dry-Spun Hemp Yarn: Process and Characteristics

Dry-spun hemp yarn is produced by spinning hemp fibers directly from the dry stalks without involving water or liquid mediums, preserving the fiber's natural strength and texture. This process results in a coarser, more textured yarn that is highly durable, breathable, and suitable for textiles requiring robust performance and a rustic aesthetic. Dry-spun hemp yarn is favored in sustainable fashion and industrial applications due to its eco-friendly production, high tensile strength, and excellent moisture-wicking properties.

Fiber Texture: Wet-Spun vs Dry-Spun Hemp Yarn

Wet-spun hemp yarn exhibits a smoother, more lustrous fiber texture due to the immersion of fibers in water during the spinning process, which aligns the cellulose chains and reduces fiber stiffness. In contrast, dry-spun hemp yarn retains a coarser, rougher texture as the fibers are spun without water, resulting in a bulkier feel with less uniformity. The choice between wet-spun and dry-spun hemp yarn significantly impacts the tactile quality and application suitability, with wet-spun yarn favored for fine textiles and dry-spun yarn suited for more rugged, durable fabrics.

Strength and Durability Comparison

Wet-spun hemp yarn exhibits superior strength and durability compared to dry-spun hemp yarn due to its fiber alignment and reduced impurities during the wet spinning process. The wet spinning method produces smoother, more uniform fibers that enhance tensile strength and resistance to wear, making it ideal for heavy-duty applications. Dry-spun hemp yarn tends to have a coarser texture with more weak points, leading to lower durability under stress and abrasion.

Environmental Impact of Wet-Spinning and Dry-Spinning

Wet-spun hemp yarn production consumes significantly more water and energy compared to dry-spun methods due to its reliance on aqueous solutions for fiber alignment and purification, resulting in a higher environmental footprint. Dry-spun hemp yarn uses less water and chemicals, reducing wastewater generation and associated treatment challenges, thus offering a more sustainable alternative. Selecting dry-spinning techniques supports lower greenhouse gas emissions and resource conservation in hemp textile manufacturing.

Applications: Choosing the Right Hemp Yarn Type

Wet-spun hemp yarn offers superior strength, smoothness, and durability, making it ideal for high-end textiles such as upholstery, fine apparel, and industrial fabrics. Dry-spun hemp yarn, being more textured and lightweight, is better suited for casual clothing, home textiles, and eco-friendly fashion accessories. Selecting between wet-spun and dry-spun hemp yarn depends on the desired fabric performance, end-use application, and production requirements.

Cost Efficiency: Wet-Spun and Dry-Spun Hemp Yarns

Wet-spun hemp yarn typically incurs higher production costs due to the water-intensive processing and additional drying stages, impacting overall cost efficiency compared to dry-spun hemp yarn. Dry-spun hemp yarn, with its streamlined processing that skips water usage, offers a more cost-effective solution while maintaining adequate strength and texture for various textile applications. Manufacturers prioritize dry-spun hemp yarn when aiming to balance quality with reduced operational expenses and environmental impact.

Sustainability and Eco-Friendliness

Wet-spun hemp yarn involves soaking fibers in water during processing, resulting in stronger, finer yarns with minimal chemical use, enhancing sustainability through reduced environmental impact. Dry-spun hemp yarn requires less water, making it energy-efficient but often results in coarser fibers and higher chemical dependency, potentially increasing its ecological footprint. Choosing wet-spun hemp yarn supports eco-friendly practices by maximizing fiber quality while minimizing pollutants and water waste.

Market Trends in Wet-Spun vs Dry-Spun Hemp Yarn

Market trends indicate a growing preference for wet-spun hemp yarn due to its superior strength, softness, and uniformity, making it highly sought after in premium textile applications. Dry-spun hemp yarn maintains steady demand in cost-sensitive sectors, offering a rougher texture suitable for durable industrial products and home furnishings. Increasing consumer awareness of sustainable materials drives expansion in both segments, with wet-spun hemp gaining momentum in eco-friendly fashion markets while dry-spun hemp supports rugged, utilitarian uses.

Wet-Spun Hemp Yarn vs Dry-Spun Hemp Yarn Infographic

materialdif.com

materialdif.com