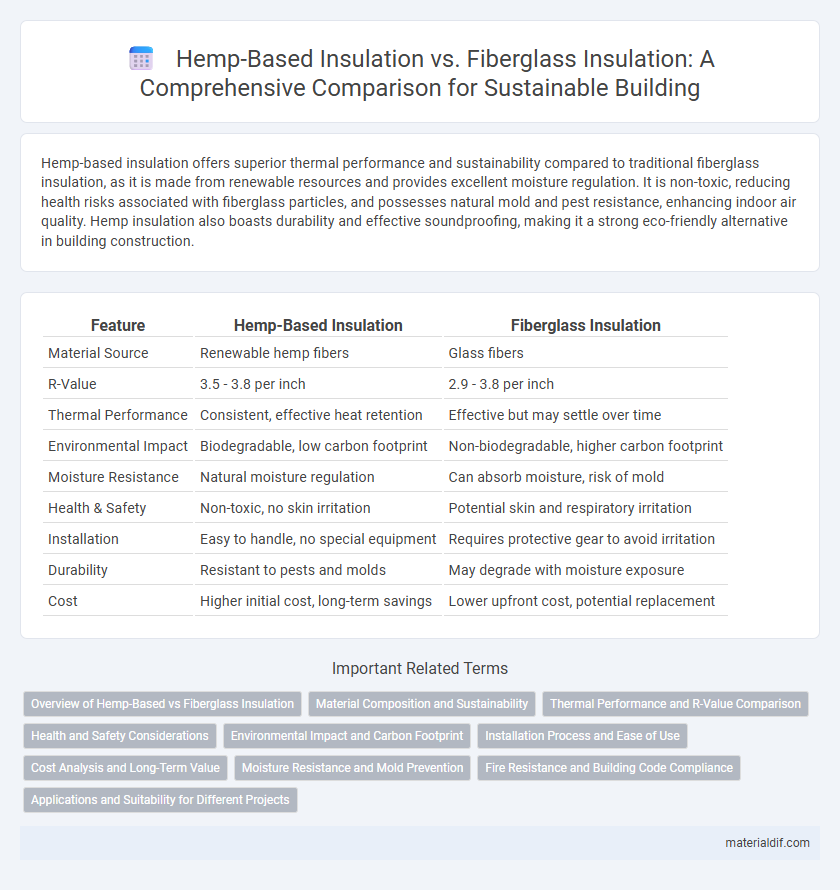

Hemp-based insulation offers superior thermal performance and sustainability compared to traditional fiberglass insulation, as it is made from renewable resources and provides excellent moisture regulation. It is non-toxic, reducing health risks associated with fiberglass particles, and possesses natural mold and pest resistance, enhancing indoor air quality. Hemp insulation also boasts durability and effective soundproofing, making it a strong eco-friendly alternative in building construction.

Table of Comparison

| Feature | Hemp-Based Insulation | Fiberglass Insulation |

|---|---|---|

| Material Source | Renewable hemp fibers | Glass fibers |

| R-Value | 3.5 - 3.8 per inch | 2.9 - 3.8 per inch |

| Thermal Performance | Consistent, effective heat retention | Effective but may settle over time |

| Environmental Impact | Biodegradable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Moisture Resistance | Natural moisture regulation | Can absorb moisture, risk of mold |

| Health & Safety | Non-toxic, no skin irritation | Potential skin and respiratory irritation |

| Installation | Easy to handle, no special equipment | Requires protective gear to avoid irritation |

| Durability | Resistant to pests and molds | May degrade with moisture exposure |

| Cost | Higher initial cost, long-term savings | Lower upfront cost, potential replacement |

Overview of Hemp-Based vs Fiberglass Insulation

Hemp-based insulation offers a sustainable and eco-friendly alternative to traditional fiberglass insulation, providing excellent thermal performance and natural moisture regulation. Unlike fiberglass, hemp insulation is biodegradable, non-toxic, and less likely to cause respiratory irritation during installation. Its renewable cultivation and superior soundproofing properties make hemp insulation a preferred choice for green building projects aiming to reduce environmental impact.

Material Composition and Sustainability

Hemp-based insulation is derived from the natural fibers of the hemp plant, offering a renewable, biodegradable alternative to traditional fiberglass insulation, which is made from spun glass fibers and involves energy-intensive manufacturing. The sustainable cultivation of hemp enhances carbon sequestration and reduces reliance on non-renewable resources, while fiberglass production relies heavily on fossil fuels and generates more waste. Hemp insulation provides superior moisture regulation and thermal performance, contributing to healthier indoor air quality and reduced environmental impact.

Thermal Performance and R-Value Comparison

Hemp-based insulation offers superior thermal performance with an R-value ranging from 3.5 to 3.8 per inch, providing efficient heat retention and breathability compared to fiberglass insulation's R-value of about 2.2 to 2.7 per inch. Hemp's natural fiber structure enhances moisture regulation, reducing the risk of mold and improving indoor air quality, while fiberglass can trap moisture and degrade over time. The sustainable sourcing and biodegradability of hemp make it a preferable eco-friendly alternative without compromising insulation effectiveness.

Health and Safety Considerations

Hemp-based insulation offers superior health and safety benefits compared to traditional fiberglass insulation due to its natural, non-toxic, and hypoallergenic properties, reducing risks of respiratory irritation and skin allergies. Unlike fiberglass, which can release harmful microscopic fibers during installation and over time, hemp insulation is biodegradable and resistant to mold, pests, and fire without harmful chemical additives. Its sustainable production process also avoids exposure to carcinogenic substances often associated with synthetic insulation materials.

Environmental Impact and Carbon Footprint

Hemp-based insulation significantly reduces environmental impact by utilizing a renewable, fast-growing crop that sequesters CO2 during cultivation, unlike fiberglass insulation, which relies on energy-intensive manufacturing processes and non-renewable raw materials. The carbon footprint of hemp insulation is lower due to its biodegradability and minimal chemical treatment, promoting a circular lifecycle and reducing landfill waste. Hemp insulation also offers superior thermal performance, enhancing energy efficiency in buildings and further decreasing greenhouse gas emissions associated with heating and cooling.

Installation Process and Ease of Use

Hemp-based insulation offers a straightforward installation process with its lightweight, flexible batts that fit snugly between studs and joists, reducing the need for additional cutting or framing adjustments. Unlike fiberglass insulation, which requires protective gear due to irritating fibers and can be challenging to handle without causing gaps, hemp insulation is non-toxic, dust-free, and easier to work with, making it suitable for DIY projects. The natural resilience and moisture-regulating properties of hemp further simplify installation by minimizing the risk of compression and sagging over time.

Cost Analysis and Long-Term Value

Hemp-based insulation typically costs 15-30% more upfront compared to traditional fiberglass insulation, but offers superior thermal performance and moisture resistance that enhances energy savings over time. Its natural biodegradability and durability reduce the need for frequent replacements or repairs, resulting in lower lifecycle costs. Over a 20-year period, hemp insulation can offer up to 25% greater overall cost efficiency when factoring in energy savings and environmental benefits.

Moisture Resistance and Mold Prevention

Hemp-based insulation offers superior moisture resistance compared to fiberglass insulation due to its natural hygroscopic properties, which allow it to regulate humidity effectively and reduce condensation risks. Unlike fiberglass, hemp fibers resist mold growth by maintaining a dry environment and inhibiting fungal development, enhancing indoor air quality and durability. This makes hemp insulation an eco-friendly choice that promotes healthier, longer-lasting building structures.

Fire Resistance and Building Code Compliance

Hemp-based insulation offers superior fire resistance compared to traditional fiberglass insulation, as hemp fibers naturally resist ignition and slow flame spread, enhancing building safety. Many building codes now recognize hemp insulation for its non-toxic, fire-resistant properties, facilitating easier compliance during construction or renovation projects. Choosing hemp insulation supports eco-friendly building practices while meeting stringent fire safety and code requirements.

Applications and Suitability for Different Projects

Hemp-based insulation offers superior breathability and natural resistance to mold and pests, making it ideal for eco-friendly residential and commercial buildings where indoor air quality is a priority. Fiberglass insulation, known for its affordability and high thermal resistance, suits large-scale construction projects requiring effective soundproofing and fire resistance. While hemp insulation excels in sustainability and moisture regulation, fiberglass remains preferable for budget-sensitive applications demanding quick installation and widespread availability.

Hemp-Based Insulation vs Fiberglass Insulation Infographic

materialdif.com

materialdif.com