Hemp biocomposites offer a sustainable alternative to carbon fiber composites by utilizing natural fibers that reduce environmental impact and promote biodegradability. While carbon fiber composites provide superior strength-to-weight ratios and durability, hemp biocomposites excel in cost-effectiveness and eco-friendly applications. Advances in hemp fiber processing are steadily improving mechanical properties, making hemp biocomposites increasingly viable for automotive, construction, and consumer goods industries.

Table of Comparison

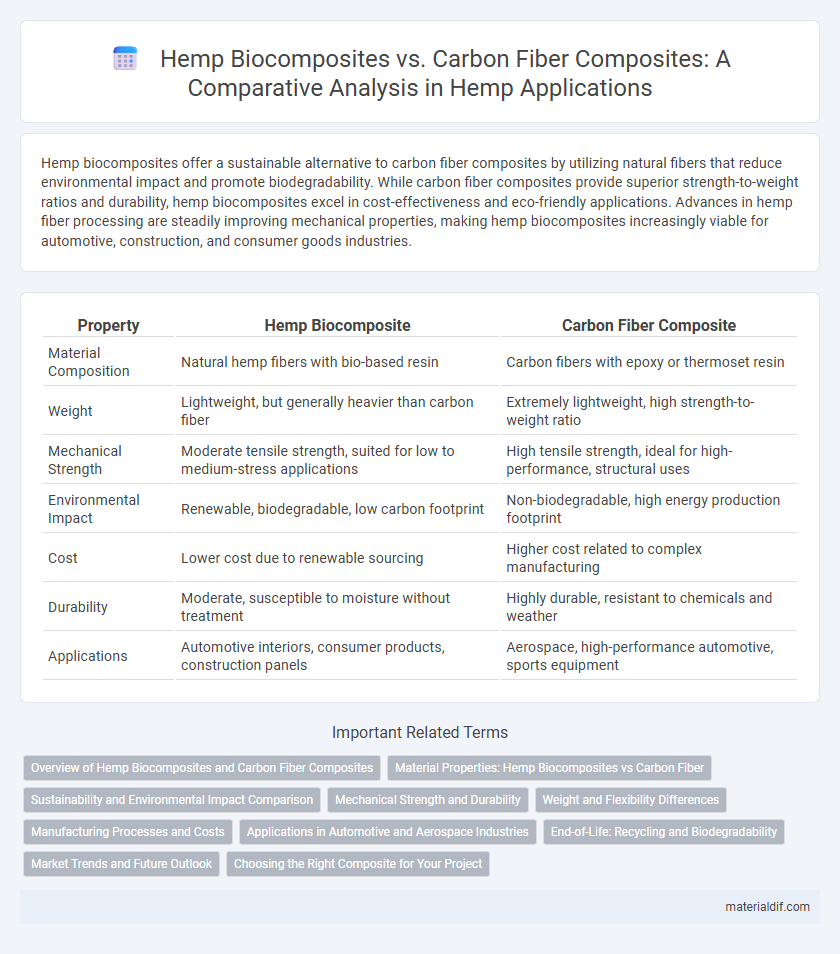

| Property | Hemp Biocomposite | Carbon Fiber Composite |

|---|---|---|

| Material Composition | Natural hemp fibers with bio-based resin | Carbon fibers with epoxy or thermoset resin |

| Weight | Lightweight, but generally heavier than carbon fiber | Extremely lightweight, high strength-to-weight ratio |

| Mechanical Strength | Moderate tensile strength, suited for low to medium-stress applications | High tensile strength, ideal for high-performance, structural uses |

| Environmental Impact | Renewable, biodegradable, low carbon footprint | Non-biodegradable, high energy production footprint |

| Cost | Lower cost due to renewable sourcing | Higher cost related to complex manufacturing |

| Durability | Moderate, susceptible to moisture without treatment | Highly durable, resistant to chemicals and weather |

| Applications | Automotive interiors, consumer products, construction panels | Aerospace, high-performance automotive, sports equipment |

Overview of Hemp Biocomposites and Carbon Fiber Composites

Hemp biocomposites consist of natural hemp fibers combined with biodegradable or polymer matrices, offering lightweight, renewable, and eco-friendly alternatives to synthetic composites. Carbon fiber composites are composed of carbon fibers embedded in a polymer resin, providing superior strength, stiffness, and durability but with higher environmental impact and cost. Hemp biocomposites excel in sustainability and cost-effectiveness, while carbon fiber composites dominate in high-performance applications requiring exceptional mechanical properties.

Material Properties: Hemp Biocomposites vs Carbon Fiber

Hemp biocomposites exhibit lower density and enhanced biodegradability compared to carbon fiber composites, making them a sustainable alternative for lightweight applications. While carbon fiber composites offer superior tensile strength and stiffness, hemp fibers provide better impact resistance and vibration damping, benefiting specific automotive and construction uses. The thermal stability of carbon fiber composites surpasses that of hemp biocomposites, though the latter contributes to reduced environmental impact through renewable sourcing and lower energy consumption during production.

Sustainability and Environmental Impact Comparison

Hemp biocomposites offer a significantly lower environmental impact compared to carbon fiber composites due to their renewable resource base and biodegradability. The cultivation of hemp requires less energy-intensive processing and sequesters carbon dioxide, reducing overall carbon footprint, whereas carbon fiber production involves high energy consumption and non-recyclable materials. Sustainable hemp composites contribute to waste reduction and promote circular economy principles, positioning them as environmentally advantageous alternatives in composite manufacturing.

Mechanical Strength and Durability

Hemp biocomposites exhibit lower mechanical strength compared to carbon fiber composites, with tensile strengths typically ranging from 30 to 60 MPa versus carbon fiber's 600 to 1500 MPa range. Durability-wise, carbon fiber composites outperform hemp biocomposites due to superior resistance to environmental factors such as moisture, UV radiation, and chemical exposure. Despite these differences, hemp biocomposites offer advantages in biodegradability and lightweight properties, making them suitable for applications where sustainability is prioritized over maximum strength and durability.

Weight and Flexibility Differences

Hemp biocomposites offer significantly lower weight compared to carbon fiber composites, making them ideal for applications where lightweight materials enhance efficiency and reduce energy consumption. These biocomposites exhibit superior flexibility, allowing better impact resistance and deformation under stress without cracking, unlike the more rigid and brittle carbon fiber composites. The combination of hemp fiber's natural flexibility and low density contributes to sustainable material choices in automotive and construction industries seeking eco-friendly alternatives.

Manufacturing Processes and Costs

Hemp biocomposites are produced using low-energy processes involving natural fibers combined with biodegradable resins, resulting in reduced manufacturing costs compared to carbon fiber composites which require energy-intensive production and expensive raw materials. The simplicity of hemp fiber extraction and composite fabrication leads to faster turnaround times and lower capital investment in manufacturing equipment. Cost analysis reveals hemp biocomposites can reduce expenses by up to 40% while maintaining sufficient mechanical performance for many industrial applications.

Applications in Automotive and Aerospace Industries

Hemp biocomposites offer lightweight, sustainable alternatives to carbon fiber composites in automotive and aerospace industries, reducing environmental impact while maintaining structural integrity. These biocomposites are increasingly used for interior panels, door components, and seating structures due to their natural fiber reinforcement and biodegradability. Despite carbon fiber's superior strength-to-weight ratio and heat resistance, hemp-based materials provide cost-effective, eco-friendly solutions suitable for non-critical load-bearing parts.

End-of-Life: Recycling and Biodegradability

Hemp biocomposites offer superior biodegradability compared to carbon fiber composites, which are largely non-biodegradable and pose recycling challenges due to their thermoset resin matrices. The end-of-life handling of hemp biocomposites benefits from natural fiber decomposition and potential composting, reducing landfill impact and environmental pollution. Conversely, carbon fiber composites require complex mechanical or chemical recycling processes, limiting their circular economy potential and increasing waste management costs.

Market Trends and Future Outlook

Hemp biocomposites are experiencing rapid growth driven by increasing demand for sustainable and eco-friendly materials in automotive and construction industries, with a market CAGR projected at over 10% through 2030. In contrast, carbon fiber composites dominate high-performance sectors such as aerospace and sports equipment but face challenges from high costs and environmental concerns. Future trends indicate a significant shift toward hemp biocomposites due to lower carbon footprints, biodegradability, and government incentives promoting green materials.

Choosing the Right Composite for Your Project

Hemp biocomposites offer a sustainable, lightweight alternative with excellent vibration damping and lower environmental impact compared to carbon fiber composites, which provide superior strength, stiffness, and thermal resistance essential for high-performance applications. Selecting the right composite depends on project priorities such as durability requirements, weight limitations, cost constraints, and ecological considerations. For eco-friendly projects prioritizing biodegradability and cost-efficiency, hemp biocomposites are ideal, whereas carbon fiber composites suit aerospace, automotive, and sporting goods demanding peak mechanical performance.

Hemp biocomposite vs Carbon fiber composite Infographic

materialdif.com

materialdif.com