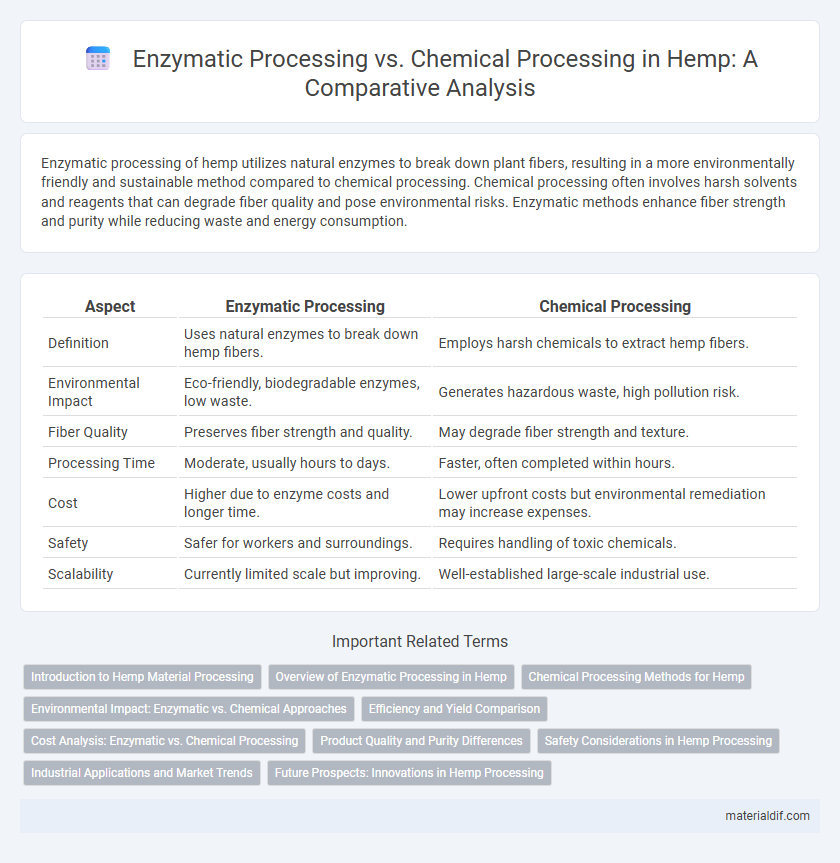

Enzymatic processing of hemp utilizes natural enzymes to break down plant fibers, resulting in a more environmentally friendly and sustainable method compared to chemical processing. Chemical processing often involves harsh solvents and reagents that can degrade fiber quality and pose environmental risks. Enzymatic methods enhance fiber strength and purity while reducing waste and energy consumption.

Table of Comparison

| Aspect | Enzymatic Processing | Chemical Processing |

|---|---|---|

| Definition | Uses natural enzymes to break down hemp fibers. | Employs harsh chemicals to extract hemp fibers. |

| Environmental Impact | Eco-friendly, biodegradable enzymes, low waste. | Generates hazardous waste, high pollution risk. |

| Fiber Quality | Preserves fiber strength and quality. | May degrade fiber strength and texture. |

| Processing Time | Moderate, usually hours to days. | Faster, often completed within hours. |

| Cost | Higher due to enzyme costs and longer time. | Lower upfront costs but environmental remediation may increase expenses. |

| Safety | Safer for workers and surroundings. | Requires handling of toxic chemicals. |

| Scalability | Currently limited scale but improving. | Well-established large-scale industrial use. |

Introduction to Hemp Material Processing

Enzymatic processing of hemp utilizes natural enzymes to break down cellulose and lignin, enhancing fiber quality and preserving environmental integrity compared to traditional chemical methods. Chemical processing often involves harsh solvents like sodium hydroxide or sulfuric acid, which can damage fibers and generate toxic waste, impacting sustainability. Choosing enzymatic methods improves the efficiency of hemp material processing while reducing ecological footprint and promoting biocompatible end-products.

Overview of Enzymatic Processing in Hemp

Enzymatic processing in hemp utilizes specific enzymes to break down cellulose and hemicellulose efficiently, resulting in higher purity fiber extraction compared to chemical methods. This eco-friendly approach reduces the use of harsh chemicals, lowers energy consumption, and preserves the natural properties of hemp fibers. Enhanced enzyme formulations tailored for hemp improve yield and quality, supporting sustainable industrial applications in textiles and bioplastics.

Chemical Processing Methods for Hemp

Chemical processing methods for hemp involve the use of solvents such as hexane, ethanol, or acetone to extract cannabinoids, terpenes, and other valuable compounds efficiently. These methods enable high yield and purity but may introduce solvent residues that require thorough removal to ensure product safety. The chemical processing of hemp is widely employed in producing CBD oils, concentrates, and isolates due to its scalability and consistency compared to enzymatic alternatives.

Environmental Impact: Enzymatic vs. Chemical Approaches

Enzymatic processing of hemp fibers significantly reduces environmental impact by using biodegradable enzymes that lower energy consumption and minimize toxic chemical waste compared to traditional chemical processing methods. Chemical processing often relies on harsh solvents and alkalis that pollute water sources and generate hazardous byproducts, contributing to soil degradation and ecosystem harm. Enzymatic approaches promote sustainable hemp fiber extraction with enhanced biodegradability and reduced carbon footprint, supporting eco-friendly industrial practices.

Efficiency and Yield Comparison

Enzymatic processing of hemp typically offers higher efficiency by preserving cellulose and enhancing fiber quality through specific enzyme action, leading to improved yield with reduced chemical waste. Chemical processing, while faster in breaking down non-cellulosic components, often results in lower fiber integrity and increased environmental impact due to harsh solvents. Studies indicate enzymatic methods can increase bast fiber yield by up to 20% compared to traditional chemical retting processes, optimizing both product quality and sustainability.

Cost Analysis: Enzymatic vs. Chemical Processing

Enzymatic processing of hemp fiber offers lower operational costs due to reduced energy consumption and minimized use of harsh chemicals, resulting in less wastewater treatment expense. In contrast, chemical processing demands significant investment in chemical reagents and extensive wastewater management, increasing overall production costs. Although enzymatic methods may require higher initial enzyme procurement costs, their environmental benefits and decreased regulatory compliance expenses contribute to a more cost-effective solution in large-scale hemp processing.

Product Quality and Purity Differences

Enzymatic processing of hemp preserves product quality by targeting specific compounds, resulting in higher purity and fewer contaminants compared to chemical processing, which often involves harsh solvents that can degrade cannabinoids and terpenes. Enzymatic methods maintain the natural profile of hemp extracts, enhancing bioavailability and therapeutic efficacy. Chemical processing increases the risk of residual solvents, potentially compromising safety and necessitating extensive purification steps.

Safety Considerations in Hemp Processing

Enzymatic processing in hemp production utilizes natural catalysts to break down biomass, significantly reducing the risk of harmful chemical exposure for workers and lowering environmental impact. Chemical processing often involves hazardous solvents and reagents that pose health and safety risks, including combustible fumes and toxic residues. Prioritizing enzymatic methods enhances workplace safety and aligns with sustainable hemp processing standards.

Industrial Applications and Market Trends

Enzymatic processing in hemp extraction enhances fiber quality and preserves bioactive compounds, making it ideal for textile and pharmaceutical industries. Chemical processing, while faster and scalable, often compromises material purity but remains dominant in large-scale industrial hemp oil production. Market trends indicate a growing preference for enzymatic methods driven by demand for sustainable and high-purity hemp products in health, cosmetics, and biodegradable materials sectors.

Future Prospects: Innovations in Hemp Processing

Enzymatic processing of hemp, leveraging specific enzymes to break down cellulose and lignin, offers a sustainable alternative to traditional chemical methods, reducing environmental impact and improving fiber quality. Innovations in enzyme engineering and biocatalysis are expected to enhance processing efficiency, enabling large-scale, eco-friendly production of hemp-based textiles and composites. Future prospects highlight integration of enzymatic methods with emerging biorefinery technologies, driving advancements in cost-effectiveness and product customization for diverse industrial applications.

Enzymatic processing vs Chemical processing Infographic

materialdif.com

materialdif.com