Hemp bast fiber, derived from the outer bark of the stalk, is known for its strength, flexibility, and durability, making it ideal for textiles, ropes, and composites. In contrast, hemp hurd, composed of the woody inner core, provides excellent insulation properties and is commonly utilized in construction materials, animal bedding, and bio-composites. The distinct structural characteristics of bast fiber and hurd define their specialized applications in sustainable industries.

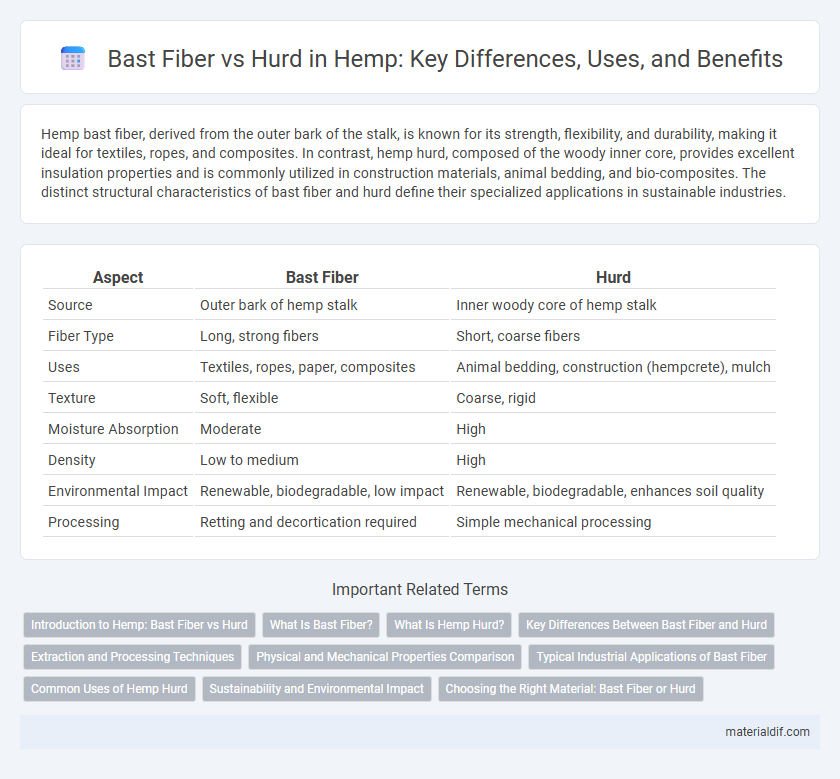

Table of Comparison

| Aspect | Bast Fiber | Hurd |

|---|---|---|

| Source | Outer bark of hemp stalk | Inner woody core of hemp stalk |

| Fiber Type | Long, strong fibers | Short, coarse fibers |

| Uses | Textiles, ropes, paper, composites | Animal bedding, construction (hempcrete), mulch |

| Texture | Soft, flexible | Coarse, rigid |

| Moisture Absorption | Moderate | High |

| Density | Low to medium | High |

| Environmental Impact | Renewable, biodegradable, low impact | Renewable, biodegradable, enhances soil quality |

| Processing | Retting and decortication required | Simple mechanical processing |

Introduction to Hemp: Bast Fiber vs Hurd

Hemp consists primarily of two fiber types: bast fiber and hurd. Bast fiber, derived from the outer bark, is long, strong, and highly valued for textiles and composites, while hurd, the woody inner core, is coarse and commonly used for animal bedding, construction materials, and biofuel. Understanding the distinct properties of bast fiber and hurd is essential for optimizing hemp's industrial applications and economic value.

What Is Bast Fiber?

Bast fiber is the strong, fibrous material extracted from the outer layers of the hemp stalk, specifically the phloem or inner bark. It is primarily used in textiles, ropes, and paper due to its durability and flexibility compared to hurd, which is the woody core of the stalk used mainly for animal bedding and construction materials. The high cellulose content of bast fiber makes it an essential component in eco-friendly products and sustainable manufacturing processes.

What Is Hemp Hurd?

Hemp hurd refers to the woody inner core of the hemp stalk, which is coarse and lightweight compared to bast fiber that comes from the outer bark of the stalk. It is primarily used for products like animal bedding, construction materials such as hempcrete, and paper production due to its high absorbency and insulating properties. While bast fibers are valued for textiles and rope-making because of their strength and flexibility, hemp hurd's versatility lies in its ability to enhance sustainability in industrial applications.

Key Differences Between Bast Fiber and Hurd

Bast fiber and hurd are two distinct components of the hemp stalk, each with unique properties and uses. Bast fiber, found in the outer layer, is long, strong, and flexible, making it ideal for textiles, ropes, and biocomposites. Hurd, the woody core inside the stalk, is coarser and more absorbent, commonly used in construction materials, animal bedding, and particleboards.

Extraction and Processing Techniques

Bast fiber is extracted from the outer layer of the hemp stalk through processes like retting, decortication, and scutching, which separate the long fibers used for textiles, ropes, and composites. Hurd, also known as shiv, is the woody inner core of the hemp stalk and is primarily processed using mechanical crushing and grinding to produce materials for construction, animal bedding, and biomass fuel. Advanced enzymatic retting techniques improve bast fiber quality by enhancing fiber separation while minimizing damage to the hurd, optimizing the overall efficiency of hemp processing.

Physical and Mechanical Properties Comparison

Bast fiber, extracted from the outer layer of hemp stalks, exhibits higher tensile strength and flexibility compared to hurd, making it ideal for textiles and composite reinforcements. Hurd, the woody core, is denser and more brittle, offering superior compressive strength and thermal insulation properties suitable for construction and animal bedding. The distinct physical properties of bast fiber and hurd determine their specialized applications in industrial and sustainable products.

Typical Industrial Applications of Bast Fiber

Bast fiber, derived from the outer layer of the hemp stalk, finds extensive use in textiles, ropes, and composite materials due to its strength and flexibility. Its durability and moisture resistance make it ideal for automotive parts, building insulation, and eco-friendly packaging. Unlike hurd, which is primarily used for animal bedding and biofuel, bast fiber is favored in industries requiring high tensile strength and fine fiber quality.

Common Uses of Hemp Hurd

Hemp hurd, the woody inner core of the hemp stalk, is commonly used in construction materials such as hempcrete for insulation and wall building due to its lightweight, fire-resistant, and breathable properties. It also serves as an absorbent for animal bedding and as a raw material in papermaking, offering sustainability advantages over traditional wood pulp. Unlike bast fiber, which is valued for textiles and ropes, hemp hurd primarily supports industrial and environmental applications.

Sustainability and Environmental Impact

Bast fiber from hemp is prized for its strength and biodegradability, making it a sustainable alternative to synthetic fibers in textiles and composites. Hurd, the woody inner core, is highly absorbent and compostable, often utilized in eco-friendly construction materials like hempcrete that improve insulation while reducing carbon footprints. Both bast fiber and hurd contribute to hemp's low environmental impact by requiring minimal pesticides and promoting soil health through phytoremediation.

Choosing the Right Material: Bast Fiber or Hurd

Bast fiber, derived from the outer layer of the hemp stalk, offers high tensile strength and flexibility, making it ideal for textiles, ropes, and composites requiring durability. Hurd, the woody inner core, provides excellent insulation and absorbency, suited for construction materials like hempcrete and animal bedding. Selecting between bast fiber and hurd depends on the specific application needs--strength and texture favor bast, while insulation and porosity prioritize hurd.

Bast Fiber vs Hurd Infographic

materialdif.com

materialdif.com