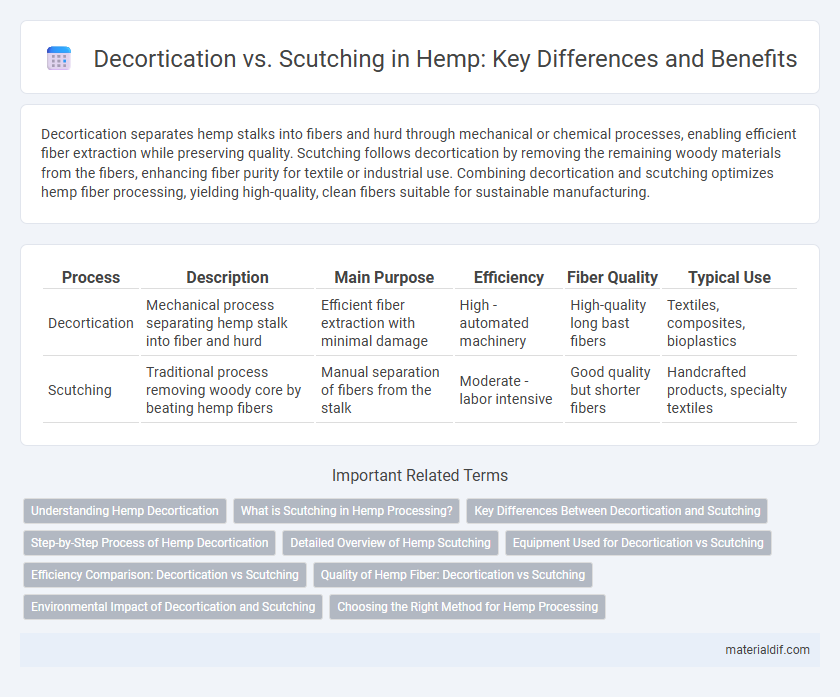

Decortication separates hemp stalks into fibers and hurd through mechanical or chemical processes, enabling efficient fiber extraction while preserving quality. Scutching follows decortication by removing the remaining woody materials from the fibers, enhancing fiber purity for textile or industrial use. Combining decortication and scutching optimizes hemp fiber processing, yielding high-quality, clean fibers suitable for sustainable manufacturing.

Table of Comparison

| Process | Description | Main Purpose | Efficiency | Fiber Quality | Typical Use |

|---|---|---|---|---|---|

| Decortication | Mechanical process separating hemp stalk into fiber and hurd | Efficient fiber extraction with minimal damage | High - automated machinery | High-quality long bast fibers | Textiles, composites, bioplastics |

| Scutching | Traditional process removing woody core by beating hemp fibers | Manual separation of fibers from the stalk | Moderate - labor intensive | Good quality but shorter fibers | Handcrafted products, specialty textiles |

Understanding Hemp Decortication

Hemp decortication involves mechanically separating the bast fibers from the woody core, optimizing fiber quality for textiles and biocomposites. This process enhances fiber strength and purity by efficiently breaking down the stalk without damaging the valuable bast fibers. In contrast, scutching is a manual or semi-mechanical method primarily used to remove bark and loosen fibers, resulting in lower fiber purity and higher labor costs.

What is Scutching in Hemp Processing?

Scutching in hemp processing is a method used to remove the woody core, or hurds, from the bast fibers after retting. This technique involves beating or scraping the hemp stalks to separate long, strong fibers essential for textiles and composites. Compared to decortication, scutching is a more manual, labor-intensive process that results in cleaner, higher-quality fiber but lower throughput.

Key Differences Between Decortication and Scutching

Decortication involves mechanically separating hemp stalks into fibers and hurd by breaking and stripping, while scutching is a manual or mechanical process that removes the woody core from the fibers after retting. Decortication yields both long bast fibers suitable for textiles and the inner hurd used for construction and animal bedding, whereas scutching primarily focuses on cleaning and refining bast fibers for higher quality textile applications. The efficiency and automation in decortication allow for higher throughput and scalability compared to the labor-intensive scutching method, influencing industrial hemp processing choices.

Step-by-Step Process of Hemp Decortication

Hemp decortication involves a step-by-step mechanical process that separates the bast fibers from the woody core, starting with harvesting and drying the stalks to reduce moisture content. The dried stalks undergo breaking and crushing to loosen the fibers, followed by scutching, which removes the woody hurd by beating and scraping the stalks. This process yields long, strong hemp fibers suitable for textiles, composites, and bioproducts, ensuring maximum fiber quality and minimal waste.

Detailed Overview of Hemp Scutching

Hemp scutching is a mechanical process that removes the woody outer layer, or hurd, from the bast fibers after retting and breaking. This technique uses specialized scutching machines equipped with rotating beaters or blades to separate long, high-quality fibers ideal for textiles and composites. Compared to decortication, which crushes and separates fibers in bulk, scutching provides cleaner, finer fibers with less damage, enhancing the fiber's strength and usability in industrial applications.

Equipment Used for Decortication vs Scutching

Decortication equipment for hemp includes mechanical decorticators that use rollers, knives, or hammer mills to separate the bast fibers from woody core rapidly, increasing fiber quality and processing efficiency. Scutching machines primarily consist of wooden or metal beaters and combs designed to manually or mechanically remove the remaining woody material and impurities from the bast fibers after decortication. Decorticators provide bulk separation and initial fiber extraction, while scutching equipment refines fibers to produce cleaner, more workable hemp fiber ideal for textile and industrial applications.

Efficiency Comparison: Decortication vs Scutching

Decortication offers higher efficiency than scutching by mechanizing the process of separating hemp fibers from the stalk, resulting in increased throughput and reduced manual labor. Scutching, a traditional method, is labor-intensive and slower, often yielding lower fiber quality due to inconsistent separation. Industrial-scale hemp processing favors decortication for its ability to deliver cleaner fibers with less waste, ultimately improving production efficiency.

Quality of Hemp Fiber: Decortication vs Scutching

Decortication produces higher quality hemp fiber by efficiently separating bast fibers from the woody core with minimal damage, preserving fiber strength and length. Scutching often results in lower fiber quality due to mechanical beating that can break fibers and introduce impurities. Choosing decortication enhances fiber purity, making it ideal for textiles and composites requiring superior durability and appearance.

Environmental Impact of Decortication and Scutching

Decortication of hemp involves mechanically separating the bast fibers from the woody core, which generates less waste and reduces water consumption compared to traditional scutching methods that rely on repeated beating and washing. The environmental impact of decortication is lower carbon emissions due to its energy-efficient process and decreased need for chemical treatments, whereas scutching often results in higher water pollution from wastewater discharge. Optimizing decortication technology promotes sustainable hemp fiber production by minimizing soil degradation and conserving natural resources.

Choosing the Right Method for Hemp Processing

Decortication efficiently separates hemp bast fibers from the woody core by mechanically breaking down stalks, ideal for large-scale industrial processing and producing high-quality textile fibers. Scutching, a traditional method, uses hammering or beating to remove the woody core but is labor-intensive and better suited for small-scale or artisanal hemp fiber preparation. Selecting between decortication and scutching depends on desired fiber quality, processing scale, and end-use applications such as textiles, composites, or paper products.

Decortication vs scutching Infographic

materialdif.com

materialdif.com