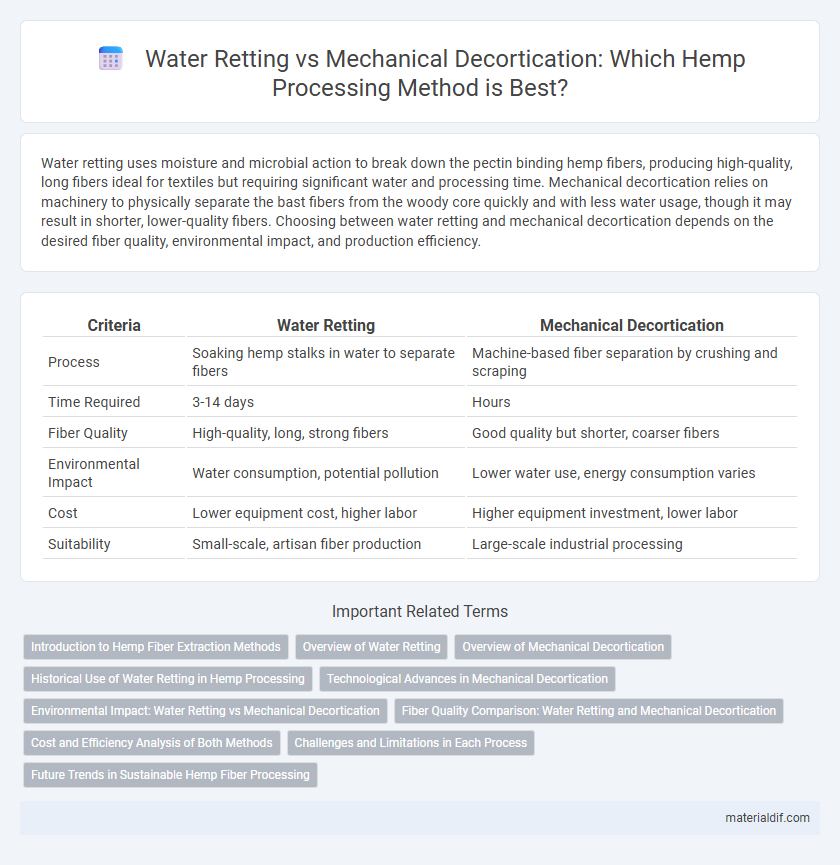

Water retting uses moisture and microbial action to break down the pectin binding hemp fibers, producing high-quality, long fibers ideal for textiles but requiring significant water and processing time. Mechanical decortication relies on machinery to physically separate the bast fibers from the woody core quickly and with less water usage, though it may result in shorter, lower-quality fibers. Choosing between water retting and mechanical decortication depends on the desired fiber quality, environmental impact, and production efficiency.

Table of Comparison

| Criteria | Water Retting | Mechanical Decortication |

|---|---|---|

| Process | Soaking hemp stalks in water to separate fibers | Machine-based fiber separation by crushing and scraping |

| Time Required | 3-14 days | Hours |

| Fiber Quality | High-quality, long, strong fibers | Good quality but shorter, coarser fibers |

| Environmental Impact | Water consumption, potential pollution | Lower water use, energy consumption varies |

| Cost | Lower equipment cost, higher labor | Higher equipment investment, lower labor |

| Suitability | Small-scale, artisan fiber production | Large-scale industrial processing |

Introduction to Hemp Fiber Extraction Methods

Water retting and mechanical decortication are two primary methods for extracting hemp fibers, each influencing fiber quality and processing efficiency. Water retting involves soaking hemp stalks in water to break down pectins, resulting in softer, finer fibers ideal for textiles. Mechanical decortication uses machinery to separate fibers from the woody core, offering faster processing and higher fiber yield suitable for industrial applications like composites and construction materials.

Overview of Water Retting

Water retting is a traditional hemp fiber extraction method that uses microbial activity to break down pectin, separating fibers from the stalk. This bioprocess requires controlled soaking in water, typically lasting from 7 to 14 days, to achieve optimal fiber quality and strength. Compared to mechanical decortication, water retting produces finer, softer fibers but involves higher water usage and longer processing times.

Overview of Mechanical Decortication

Mechanical decortication is a modern hemp processing method that separates fibers from the stalk using machines, offering faster and more consistent fiber extraction than traditional water retting. This technique reduces water usage and environmental impact while improving fiber quality by minimizing microbial damage. Equipment such as hammer mills and roller decorticators optimize fiber yield and are increasingly favored in sustainable hemp production.

Historical Use of Water Retting in Hemp Processing

Water retting, a traditional hemp processing method used for centuries, relies on microbial activity to break down pectins, facilitating fiber separation. Historical water retting practices often involved submerging hemp stalks in ponds or rivers, promoting natural fermentation crucial for obtaining high-quality bast fibers. This method contrasts with mechanical decortication, which uses machines to physically separate fibers but may compromise fiber integrity and environmental sustainability.

Technological Advances in Mechanical Decortication

Mechanical decortication has seen significant technological advances, incorporating sophisticated machinery such as roller crushers, hammer mills, and ultrasonic devices to efficiently separate hemp fibers from the stalk with minimal fiber damage. These innovations enhance fiber quality, increase processing speed, and reduce water consumption compared to traditional water retting, which relies on microbial breakdown and requires extended soaking periods. Modern mechanical decorticators optimize fiber extraction for textile and biocomposite industries, promoting sustainable hemp processing by minimizing environmental impact and boosting economic viability.

Environmental Impact: Water Retting vs Mechanical Decortication

Water retting in hemp processing involves soaking stalks in water to separate fibers, which can produce nutrient-rich but oxygen-depleting wastewater impacting aquatic ecosystems. Mechanical decortication uses machinery to physically separate fibers, significantly reducing water consumption and minimizing chemical runoff, making it a more sustainable option. Choosing mechanical decortication reduces environmental pollution and conserves water resources, aligning with eco-friendly hemp production practices.

Fiber Quality Comparison: Water Retting and Mechanical Decortication

Water retting produces hemp fibers with higher tensile strength and better flexibility due to the more effective removal of pectin and lignin, resulting in finer and more uniform fibers ideal for textile applications. Mechanical decortication, while faster and chemical-free, often yields coarser fibers with higher residual impurities, leading to lower fiber quality and reduced performance in high-grade industrial uses. Comparative studies indicate that water retting remains superior for fiber quality, though mechanical decortication is favored for sustainability and processing efficiency.

Cost and Efficiency Analysis of Both Methods

Water retting of hemp involves soaking stalks to separate fibers, resulting in lower initial equipment costs but higher labor and water management expenses, while mechanical decortication uses specialized machinery that demands higher upfront investment yet offers faster processing and greater fiber yield. Mechanical decortication improves efficiency by significantly reducing processing time and water usage compared to water retting, which can take days to weeks and raises environmental concerns due to water pollution. Cost analysis shows mechanical decortication's long-term benefits in scalability and fiber quality outweigh its initial capital, making it favorable for commercial hemp fiber production.

Challenges and Limitations in Each Process

Water retting involves submerging hemp stalks in water to break down pectins, but it faces challenges such as high water consumption, slow processing times, and potential water pollution from organic waste release. Mechanical decortication offers faster fiber extraction and lower environmental impact but struggles with incomplete separation, fiber damage, and difficulty handling varying stalk moisture levels. Both methods require optimization to balance fiber quality, environmental sustainability, and operational efficiency.

Future Trends in Sustainable Hemp Fiber Processing

Water retting, a traditional method involving microbial breakdown of hemp stalks in water, is energy-intensive and generates wastewater challenges, prompting a shift toward mechanical decortication in sustainable hemp fiber processing. Mechanical decortication, using modern machinery to separate fibers efficiently, reduces environmental impact by minimizing water use and waste, aligning with circular economy principles. Future trends emphasize integrating advanced sensor technologies and AI-driven automation to optimize fiber quality and processing speed, supporting eco-friendly and cost-effective hemp fiber production.

Water Retting vs Mechanical Decortication Infographic

materialdif.com

materialdif.com