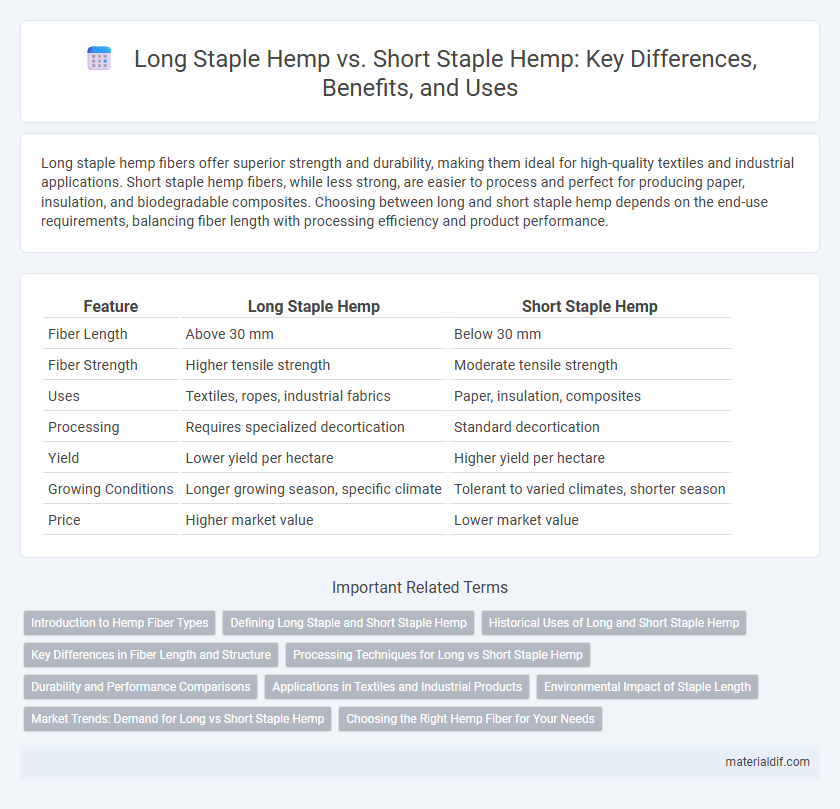

Long staple hemp fibers offer superior strength and durability, making them ideal for high-quality textiles and industrial applications. Short staple hemp fibers, while less strong, are easier to process and perfect for producing paper, insulation, and biodegradable composites. Choosing between long and short staple hemp depends on the end-use requirements, balancing fiber length with processing efficiency and product performance.

Table of Comparison

| Feature | Long Staple Hemp | Short Staple Hemp |

|---|---|---|

| Fiber Length | Above 30 mm | Below 30 mm |

| Fiber Strength | Higher tensile strength | Moderate tensile strength |

| Uses | Textiles, ropes, industrial fabrics | Paper, insulation, composites |

| Processing | Requires specialized decortication | Standard decortication |

| Yield | Lower yield per hectare | Higher yield per hectare |

| Growing Conditions | Longer growing season, specific climate | Tolerant to varied climates, shorter season |

| Price | Higher market value | Lower market value |

Introduction to Hemp Fiber Types

Long staple hemp fibers, typically measuring over 50 millimeters, offer superior strength, durability, and smoothness, making them ideal for high-quality textiles and industrial products. Short staple hemp fibers, usually under 50 millimeters, are coarser and more suited for applications such as paper production, insulation, and bio-composites. Understanding the distinction between long and short staple hemp fibers is crucial for optimizing their use in various sustainable manufacturing processes.

Defining Long Staple and Short Staple Hemp

Long staple hemp fibers typically measure over 50 millimeters in length, offering greater strength and durability ideal for high-quality textiles and industrial applications. Short staple hemp fibers, generally shorter than 50 millimeters, are better suited for products like paper, insulation, and nonwoven materials due to their finer texture and easier processing. The distinction between long staple and short staple hemp is critical for optimizing fiber use based on application-specific performance requirements.

Historical Uses of Long and Short Staple Hemp

Long staple hemp fibers, characterized by their length of 2-5 meters, have been historically used for producing high-quality ropes, sails, and textiles essential for maritime and industrial applications due to their strength and durability. Short staple hemp fibers, typically measuring less than 2 centimeters, were predominantly utilized in the manufacture of coarse fabrics, paper, and insulation materials, fulfilling everyday functional needs. Historical records highlight that long staple hemp cultivation was vital in naval industries from the 16th to 19th centuries, whereas short staple hemp found widespread use in rural economies for domestic products and paper production.

Key Differences in Fiber Length and Structure

Long staple hemp fibers typically measure between 50 to 150 millimeters, offering superior strength and flexibility compared to short staple hemp, which ranges from 10 to 50 millimeters in length. The fiber structure of long staple hemp is more aligned and less coarse, making it ideal for high-quality textile production, whereas short staple fibers are coarser and better suited for composite materials and insulation. These differences in fiber length and structure significantly influence the applications and processing methods used in the hemp industry.

Processing Techniques for Long vs Short Staple Hemp

Long staple hemp requires more advanced processing techniques such as decortication and retting to separate the fibers without damaging their length, enabling the production of high-quality textiles and composites. Short staple hemp fibers undergo mechanical processing methods like breaking, scutching, and hackling, which are more suited for lower-grade products such as insulation, paper, and bio-composites. Optimizing the retting duration and decortication pressure for long staple hemp ensures maximum fiber strength and fineness, whereas short staple hemp benefits from faster mechanical processing to maximize throughput and cost-efficiency.

Durability and Performance Comparisons

Long staple hemp fibers exhibit superior durability due to their extended length, which enhances tensile strength and resistance to wear, making them ideal for high-performance textiles and industrial applications. Short staple hemp fibers are generally coarser and less uniform, resulting in lower tensile strength and reduced longevity, but they remain useful for insulation and composite materials where extreme durability is less critical. Performance comparisons highlight that long staple hemp fibers maintain structural integrity under stress better than short staple fibers, contributing to their preference in products demanding consistent strength and durability.

Applications in Textiles and Industrial Products

Long staple hemp fibers, valued for their strength and length, are predominantly used in high-quality textiles such as apparel, home furnishings, and luxury fabrics, offering durability and a smooth finish. Short staple hemp fibers, with a coarser texture and shorter length, excel in industrial products including ropes, geotextiles, and composite materials, where robustness and resistance to wear are essential. The choice between long and short staple hemp fibers significantly influences the performance and application scope within the textile and industrial sectors.

Environmental Impact of Staple Length

Long staple hemp fibers have a lower environmental impact due to their higher durability and reduced need for chemical processing, which minimizes water and energy consumption. Short staple hemp requires more mechanical refining and chemical treatments, leading to increased emissions and waste. Choosing long staple hemp supports sustainable textile production by conserving natural resources and reducing ecological footprints.

Market Trends: Demand for Long vs Short Staple Hemp

Long staple hemp, known for its superior fiber strength and durability, is gaining traction in high-end textile and composite markets, driving increased demand globally. Short staple hemp remains prevalent in insulation, animal bedding, and paper production, sustaining steady market presence due to its cost-effectiveness and ease of processing. Market trends indicate a rising preference for long staple hemp as industries prioritize sustainability and performance, although short staple variants continue to hold significant value in traditional applications.

Choosing the Right Hemp Fiber for Your Needs

Long staple hemp fibers offer superior strength, durability, and smoothness, making them ideal for high-quality textiles and rope production. Short staple hemp fibers, while coarser and less durable, provide affordability and are well-suited for insulation, paper, and composite materials. Selecting the right hemp fiber depends on the specific application requirements, balancing factors such as texture, tensile strength, and cost-effectiveness.

Long staple hemp vs Short staple hemp Infographic

materialdif.com

materialdif.com