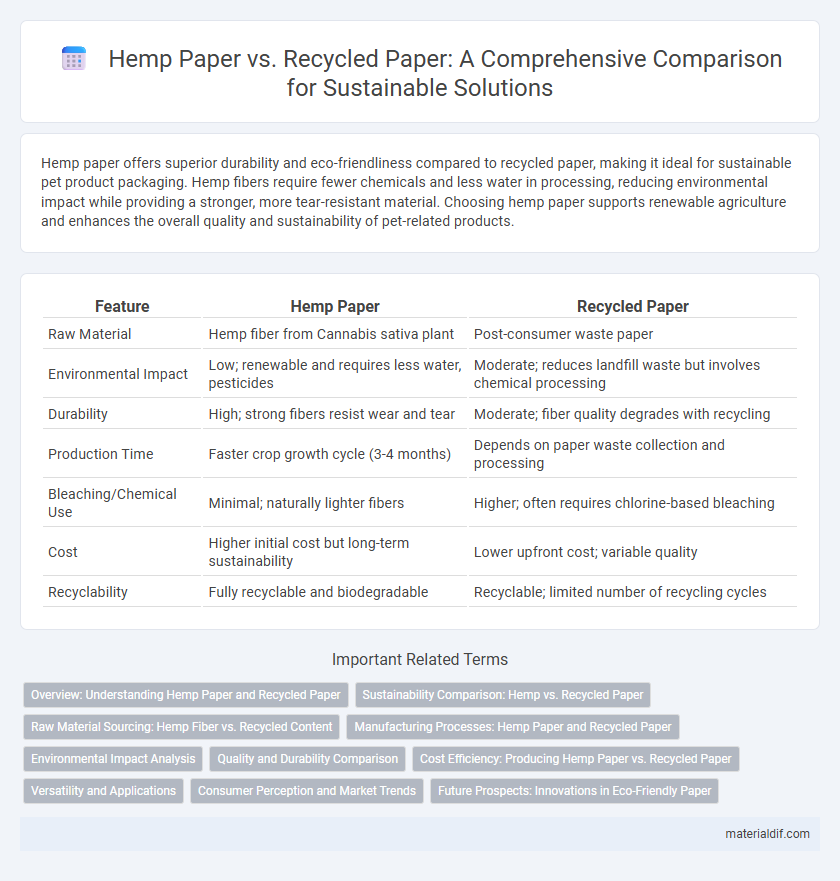

Hemp paper offers superior durability and eco-friendliness compared to recycled paper, making it ideal for sustainable pet product packaging. Hemp fibers require fewer chemicals and less water in processing, reducing environmental impact while providing a stronger, more tear-resistant material. Choosing hemp paper supports renewable agriculture and enhances the overall quality and sustainability of pet-related products.

Table of Comparison

| Feature | Hemp Paper | Recycled Paper |

|---|---|---|

| Raw Material | Hemp fiber from Cannabis sativa plant | Post-consumer waste paper |

| Environmental Impact | Low; renewable and requires less water, pesticides | Moderate; reduces landfill waste but involves chemical processing |

| Durability | High; strong fibers resist wear and tear | Moderate; fiber quality degrades with recycling |

| Production Time | Faster crop growth cycle (3-4 months) | Depends on paper waste collection and processing |

| Bleaching/Chemical Use | Minimal; naturally lighter fibers | Higher; often requires chlorine-based bleaching |

| Cost | Higher initial cost but long-term sustainability | Lower upfront cost; variable quality |

| Recyclability | Fully recyclable and biodegradable | Recyclable; limited number of recycling cycles |

Overview: Understanding Hemp Paper and Recycled Paper

Hemp paper is made from the fibers of the hemp plant, offering superior durability, higher cellulose content, and faster growth cycles compared to traditional wood pulp used in recycled paper. Recycled paper involves reprocessing used paper products, reducing waste but often resulting in lower fiber quality and strength due to fiber degradation. Both materials contribute to environmental sustainability, but hemp paper provides enhanced longevity and less chemical processing, making it a more eco-friendly alternative.

Sustainability Comparison: Hemp vs. Recycled Paper

Hemp paper offers superior sustainability benefits compared to recycled paper due to its rapid growth cycle, requiring only four months to harvest, which significantly reduces deforestation and land use. Unlike recycled paper, which degrades in quality after multiple reuse cycles and still depends on virgin wood fibers for strength, hemp fibers maintain durability and allow for up to eight recycling processes without substantial loss. Hemp cultivation demands fewer pesticides and less water, enhancing soil health and minimizing environmental pollutants, making hemp paper a more eco-friendly alternative in sustainable paper production.

Raw Material Sourcing: Hemp Fiber vs. Recycled Content

Hemp paper is derived from the inner fibers of the hemp plant, offering a sustainable raw material source due to its rapid growth cycle and low pesticide requirements. In contrast, recycled paper relies on post-consumer waste, which reduces deforestation but often includes contaminants that affect fiber quality. Hemp fibers provide higher durability and longer fiber length compared to the shorter, degraded fibers found in recycled paper content.

Manufacturing Processes: Hemp Paper and Recycled Paper

Hemp paper manufacturing involves harvesting industrial hemp fibers, which are separated and processed through pulping methods such as chemical or mechanical pulping, resulting in strong, durable fiber sheets with minimal lignin content, reducing the need for harsh bleaching agents. Recycled paper production starts with collecting post-consumer waste, which undergoes deinking, pulping, and refining to remove inks and contaminants, often requiring additional chemical treatments to restore fiber quality. The manufacturing of hemp paper generally demands fewer chemicals and energy compared to recycled paper, offering a more environmentally sustainable alternative with higher fiber strength and longevity.

Environmental Impact Analysis

Hemp paper production generates significantly lower carbon emissions and uses 60% less water compared to conventional recycled paper manufacturing, reducing overall environmental strain. Hemp crops require fewer pesticides and herbicides, promoting soil health and biodiversity, unlike the chemical-intensive processes often involved in recycled paper processing. The durability and longevity of hemp paper also contribute to reduced waste, making it a more sustainable option for environmentally conscious consumers and industries.

Quality and Durability Comparison

Hemp paper exhibits significantly higher durability compared to recycled paper due to its longer fibers, which contribute to greater tensile strength and resistance to tearing. The quality of hemp paper is superior, offering a smoother texture and enhanced longevity without yellowing or deterioration over time. Unlike recycled paper, which may degrade after multiple recycling cycles, hemp paper maintains its integrity and appearance, making it ideal for archival and high-end printing purposes.

Cost Efficiency: Producing Hemp Paper vs. Recycled Paper

Hemp paper production incurs higher initial costs due to intensive processing of hemp fibers and limited industrial scale compared to recycled paper, which benefits from established recycling infrastructure and lower raw material expenses. Recycled paper utilizes post-consumer waste, significantly reducing sourcing costs, while hemp requires cultivation and harvesting investments that impact overall price. Despite higher upfront costs, hemp paper's durability and longer lifespan can contribute to cost savings in applications demanding high-quality, sustainable materials.

Versatility and Applications

Hemp paper offers superior versatility compared to recycled paper due to its stronger fibers, which make it suitable for a wide range of applications including fine art printing, archival documents, and packaging materials. Unlike recycled paper, hemp paper resists yellowing and degradation over time, enhancing its durability for long-term use in legal and official documents. Its versatility extends to eco-friendly uses in stationery and specialty papers, where recycled paper often falls short in quality and longevity.

Consumer Perception and Market Trends

Consumer perception increasingly favors hemp paper due to its sustainability, durability, and eco-friendly qualities compared to recycled paper, which is often viewed as less robust and lower quality. Market trends indicate a growing demand for hemp paper in premium packaging, stationery, and specialty printing sectors driven by environmental awareness and stricter regulations on deforestation. Hemp paper's faster renewal cycle and reduced chemical processing boost its appeal among environmentally conscious consumers and brands seeking sustainable alternatives to traditional recycled paper products.

Future Prospects: Innovations in Eco-Friendly Paper

Hemp paper offers superior sustainability due to faster growth cycles and higher cellulose content compared to recycled paper, enabling more efficient fiber extraction and stronger pulp. Innovations in enzymatic processing and mechanical pulping of hemp fibers are driving down production costs and improving texture, positioning hemp paper as a viable alternative for eco-friendly packaging and printing markets. Future prospects emphasize integrating hemp paper with biodegradable inks and advanced recycling technologies to create closed-loop, zero-waste paper products.

hemp paper vs recycled paper Infographic

materialdif.com

materialdif.com