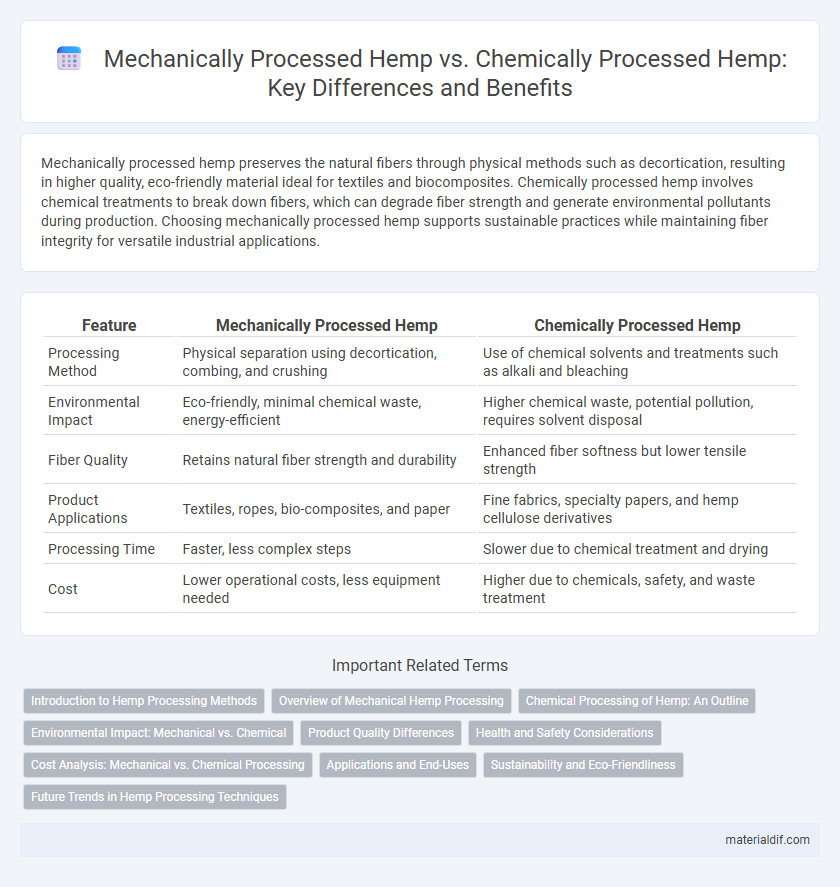

Mechanically processed hemp preserves the natural fibers through physical methods such as decortication, resulting in higher quality, eco-friendly material ideal for textiles and biocomposites. Chemically processed hemp involves chemical treatments to break down fibers, which can degrade fiber strength and generate environmental pollutants during production. Choosing mechanically processed hemp supports sustainable practices while maintaining fiber integrity for versatile industrial applications.

Table of Comparison

| Feature | Mechanically Processed Hemp | Chemically Processed Hemp |

|---|---|---|

| Processing Method | Physical separation using decortication, combing, and crushing | Use of chemical solvents and treatments such as alkali and bleaching |

| Environmental Impact | Eco-friendly, minimal chemical waste, energy-efficient | Higher chemical waste, potential pollution, requires solvent disposal |

| Fiber Quality | Retains natural fiber strength and durability | Enhanced fiber softness but lower tensile strength |

| Product Applications | Textiles, ropes, bio-composites, and paper | Fine fabrics, specialty papers, and hemp cellulose derivatives |

| Processing Time | Faster, less complex steps | Slower due to chemical treatment and drying |

| Cost | Lower operational costs, less equipment needed | Higher due to chemicals, safety, and waste treatment |

Introduction to Hemp Processing Methods

Mechanically processed hemp involves physical techniques such as decortication and micronization to separate fibers and retain natural properties, making it ideal for textiles and biocomposites. Chemically processed hemp uses solvents and chemical treatments to break down lignin and extract cellulose or CBD, enhancing purity and functionality for pharmaceuticals and refined materials. Understanding these contrasting methods is crucial for optimizing hemp's applications across industrial, medical, and environmental sectors.

Overview of Mechanical Hemp Processing

Mechanical hemp processing involves physically breaking down hemp stalks using decorticators or crushers to separate fibers from the woody core and bast. This eco-friendly method preserves fiber quality, retains natural properties, and produces hemp fibers suitable for textiles, biocomposites, and paper without chemical contaminants. Compared to chemical processing, mechanical methods reduce environmental impact by avoiding harsh solvents and preserving cellulose and lignin structures essential for industrial applications.

Chemical Processing of Hemp: An Outline

Chemical processing of hemp involves breaking down the plant using solvents, acids, or alkalis to extract fibers, cellulose, or cannabinoids efficiently. This method allows for precise control over the purity and composition of hemp derivatives, such as converting hemp biomass into biofuels, bioplastics, or CBD extracts. Despite higher energy consumption and potential environmental concerns, chemical processing enables the production of high-value hemp products with targeted functional properties.

Environmental Impact: Mechanical vs. Chemical

Mechanically processed hemp significantly reduces environmental impact by avoiding harmful solvents and chemicals, resulting in lower water and energy consumption and minimal chemical runoff. Chemically processed hemp often involves toxic solvents and bleaching agents, which contribute to soil and water pollution and increase carbon emissions during production. Choosing mechanically processed hemp supports sustainable agriculture and mitigates harmful effects on ecosystems.

Product Quality Differences

Mechanically processed hemp retains higher fiber integrity and natural nutrients, resulting in stronger, more durable textiles and biodegradable materials with enhanced environmental benefits. Chemically processed hemp often undergoes treatments that can weaken fiber strength and introduce residues, compromising product purity and reducing its suitability for sensitive applications. The choice between mechanical and chemical processing directly impacts the hemp product's quality, ecological footprint, and performance characteristics.

Health and Safety Considerations

Mechanically processed hemp involves physical methods like decortication and milling, minimizing chemical exposure and reducing risks of toxic residue, making it safer for consumers and workers. Chemically processed hemp often uses solvents or bleaching agents that may leave harmful residues, posing potential health hazards such as respiratory irritation or skin sensitization. Opting for mechanical processing enhances product safety by ensuring cleaner hemp fibers and reducing environmental pollutants.

Cost Analysis: Mechanical vs. Chemical Processing

Mechanical processing of hemp, which involves decortication and fiber separation, generally incurs lower operational costs due to reduced energy consumption and minimal chemical input, leading to more sustainable expenditure. Chemical processing, including treatments like alkaline retting or bleaching, demands higher investment in reagents, waste management, and safety protocols, significantly increasing overall production costs. Cost analysis reveals mechanical methods offer economic advantages for large-scale hemp fiber extraction, while chemical processes may yield higher purity at a premium expense.

Applications and End-Uses

Mechanically processed hemp retains its natural fiber strength and is widely used in textiles, paper production, and biodegradable composites for automotive and construction industries. Chemically processed hemp, often through retting or chemical pulping, produces finer fibers ideal for high-quality fabrics, hempcrete, and specialty papers. End-uses of mechanically processed hemp prioritize durability and sustainability, while chemically processed hemp serves applications requiring softer texture and enhanced fiber refinement.

Sustainability and Eco-Friendliness

Mechanically processed hemp retains its natural fibers without the use of harmful chemicals, resulting in lower environmental impact and reduced water and energy consumption compared to chemically processed hemp. Chemical processing often involves solvents and bleaching agents that contribute to pollution and toxic waste, making it less sustainable. Prioritizing mechanical methods supports eco-friendly production by preserving soil health and minimizing carbon emissions throughout the hemp value chain.

Future Trends in Hemp Processing Techniques

Future trends in hemp processing techniques emphasize sustainable and eco-friendly methods, with mechanically processed hemp gaining popularity due to its minimal use of chemicals and preservation of natural fiber quality. Innovations in mechanical decortication and steam explosion technologies enhance fiber yield and reduce waste, positioning these processes as cost-effective alternatives to chemical processing. Emerging research focuses on integrating enzymatic treatments with mechanical methods to improve efficiency while maintaining the structural integrity and environmental benefits of hemp fibers.

Mechanically processed hemp vs Chemically processed hemp Infographic

materialdif.com

materialdif.com