Mechanical decortication of hemp involves physically breaking down the stalks to separate fibers, preserving their natural strength and resulting in high-quality, durable fibers ideal for textiles and composites. Chemical decortication uses solvents and chemicals to dissolve non-fibrous components, producing finer fibers but potentially reducing fiber strength and introducing environmental concerns due to chemical waste. Comparing both, mechanical decortication is more eco-friendly and retains fiber integrity, while chemical methods offer higher purity at the cost of environmental impact and fiber degradation.

Table of Comparison

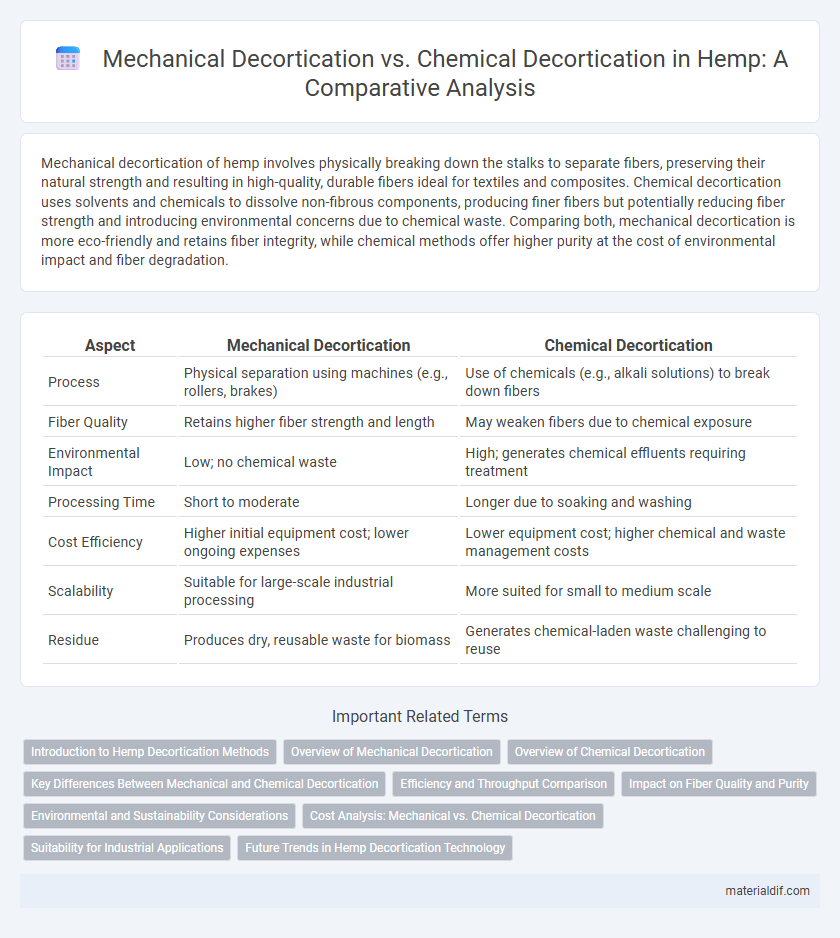

| Aspect | Mechanical Decortication | Chemical Decortication |

|---|---|---|

| Process | Physical separation using machines (e.g., rollers, brakes) | Use of chemicals (e.g., alkali solutions) to break down fibers |

| Fiber Quality | Retains higher fiber strength and length | May weaken fibers due to chemical exposure |

| Environmental Impact | Low; no chemical waste | High; generates chemical effluents requiring treatment |

| Processing Time | Short to moderate | Longer due to soaking and washing |

| Cost Efficiency | Higher initial equipment cost; lower ongoing expenses | Lower equipment cost; higher chemical and waste management costs |

| Scalability | Suitable for large-scale industrial processing | More suited for small to medium scale |

| Residue | Produces dry, reusable waste for biomass | Generates chemical-laden waste challenging to reuse |

Introduction to Hemp Decortication Methods

Mechanical decortication of hemp involves physically separating the bast fibers from the woody core using equipment like rollers or hammer mills, preserving fiber quality for textiles and composites. Chemical decortication utilizes chemical treatments such as alkali solutions to break down the pectin binding fibers to the core, enabling easier fiber extraction but potentially affecting fiber strength and environmental sustainability. Both methods are fundamental in hemp processing, influencing fiber purity, extraction efficiency, and end-product applications in industries like textiles, paper, and bioplastics.

Overview of Mechanical Decortication

Mechanical decortication of hemp involves physically breaking down the stalks using crushers, rollers, or hammer mills, which efficiently separates fibers from the woody core without the use of chemicals. This process preserves the natural integrity and strength of hemp fibers, making them highly suitable for textile, composite, and construction applications. Mechanical decortication is environmentally friendly, reduces water consumption, and produces minimal waste compared to chemical retting methods.

Overview of Chemical Decortication

Chemical decortication uses alkaline or enzymatic solutions to break down hemp stalks, effectively separating fibers from the woody core with higher purity than mechanical methods. This process enhances fiber quality by removing lignin and pectin, resulting in smoother and more consistent hemp fibers ideal for textile and composite industries. Chemical decortication also reduces fiber brittleness, improving durability and flexibility compared to fibers extracted through mechanical means.

Key Differences Between Mechanical and Chemical Decortication

Mechanical decortication of hemp relies on physical processes like crushing and scraping to separate fibers, preserving fiber length and quality for textiles and composites. Chemical decortication uses alkaline or enzymatic treatments to break down non-fibrous components, enhancing fiber cleanliness but potentially affecting environmental sustainability. Mechanical methods offer lower energy consumption and eco-friendly processing, whereas chemical methods provide more efficient fiber separation but involve chemical waste management challenges.

Efficiency and Throughput Comparison

Mechanical decortication of hemp fibers offers higher throughput and energy efficiency by physically separating fibers without chemical intervention, enabling faster processing and reduced environmental impact. Chemical decortication, while effective in breaking down pectin and lignin for finer fiber quality, tends to have longer processing times and higher operational costs due to chemical usage and waste treatment. Overall, mechanical methods excel in large-scale, high-efficiency production, whereas chemical approaches suit applications prioritizing fiber purity despite lower throughput.

Impact on Fiber Quality and Purity

Mechanical decortication retains the natural strength and length of hemp fibers, resulting in higher tensile strength and better fiber integrity, while maintaining environmental sustainability by avoiding acid or chemical exposure. Chemical decortication, often involving alkali treatments, produces fibers with increased purity but can lead to fiber damage, reduced length, and altered fiber morphology, negatively impacting the overall mechanical properties. Selecting the appropriate decortication method significantly influences hemp fiber quality, purity, and suitability for textile and composite applications.

Environmental and Sustainability Considerations

Mechanical decortication of hemp utilizes physical processes to separate fibers, significantly reducing water and chemical consumption, which lowers environmental impact and enhances sustainability. Chemical decortication, while effective in fiber separation, often involves harsh chemicals that can generate hazardous waste and require extensive wastewater treatment, posing risks to ecosystems. Choosing mechanical methods aligns better with environmentally sustainable practices by minimizing pollution and energy use, fostering a greener hemp processing industry.

Cost Analysis: Mechanical vs. Chemical Decortication

Mechanical decortication of hemp offers a cost-effective solution by reducing energy consumption and minimizing chemical expenditures, leading to lower overall operational costs compared to chemical decortication. Chemical decortication involves higher expenses due to the need for specialized chemicals, waste treatment, and longer processing times, increasing capital and environmental compliance costs. The mechanical method provides a scalable approach with reduced financial risks, making it more economically viable for large-scale hemp fiber production.

Suitability for Industrial Applications

Mechanical decortication of hemp fibers offers a sustainable and eco-friendly option ideal for industrial applications requiring high-quality, intact fibers with minimal chemical residues. Chemical decortication, while effective in breaking down fibers quickly, may introduce harmful substances affecting the suitability of hemp fibers in biocomposites, textiles, and food packaging industries. Industries prioritizing environmental impact and fiber integrity favor mechanical methods for scalable hemp processing.

Future Trends in Hemp Decortication Technology

Mechanical decortication in hemp processing is evolving with advanced fiber separation technologies that enhance efficiency and reduce environmental impact, while chemical decortication methods are focusing on eco-friendly solvents and enzymatic treatments to improve fiber quality and sustainability. Future trends emphasize integrating automation and AI-driven machinery to optimize throughput and consistency in hemp fiber extraction. Research into hybrid approaches combining mechanical and chemical techniques aims to maximize yield and quality, responding to the growing demand for high-performance hemp-based materials in textiles and composites.

Mechanical decortication vs Chemical decortication Infographic

materialdif.com

materialdif.com