Supercritical CO2 extraction yields high-purity hemp oil by using pressurized carbon dioxide without chemical residues, preserving cannabinoids and terpenes effectively. Solvent extraction often involves flammable chemicals like ethanol or butane, which can leave trace solvents and affect overall product safety. Choosing supercritical CO2 extraction ensures a cleaner, more natural hemp oil ideal for pet health products.

Table of Comparison

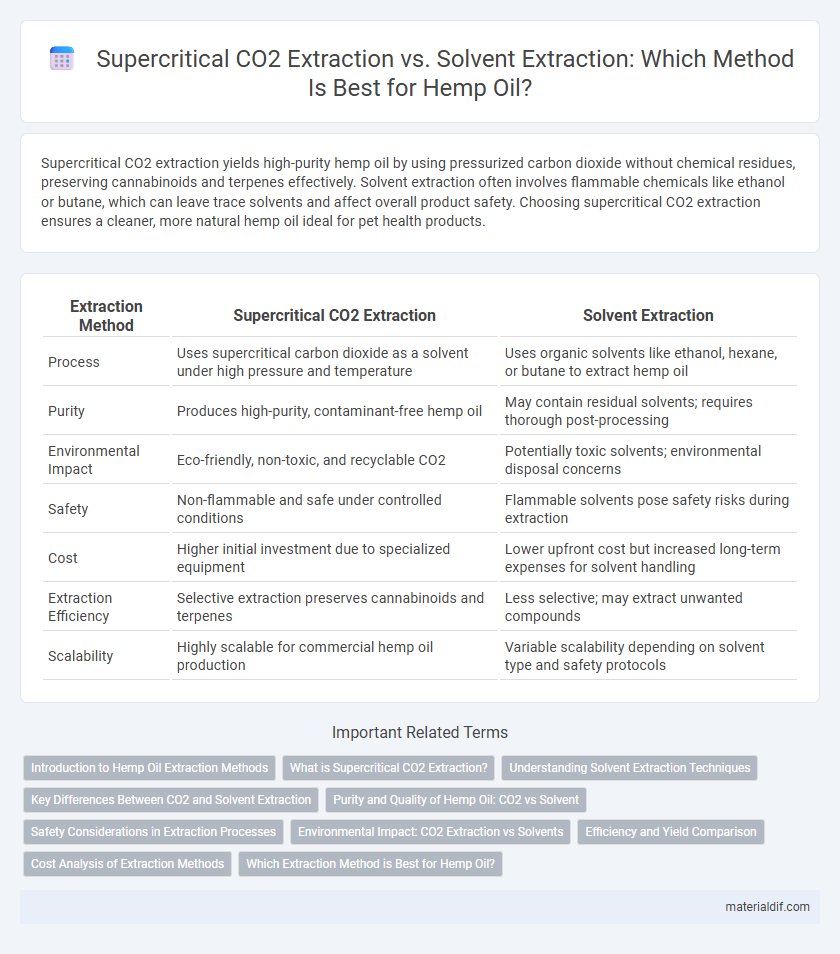

| Extraction Method | Supercritical CO2 Extraction | Solvent Extraction |

|---|---|---|

| Process | Uses supercritical carbon dioxide as a solvent under high pressure and temperature | Uses organic solvents like ethanol, hexane, or butane to extract hemp oil |

| Purity | Produces high-purity, contaminant-free hemp oil | May contain residual solvents; requires thorough post-processing |

| Environmental Impact | Eco-friendly, non-toxic, and recyclable CO2 | Potentially toxic solvents; environmental disposal concerns |

| Safety | Non-flammable and safe under controlled conditions | Flammable solvents pose safety risks during extraction |

| Cost | Higher initial investment due to specialized equipment | Lower upfront cost but increased long-term expenses for solvent handling |

| Extraction Efficiency | Selective extraction preserves cannabinoids and terpenes | Less selective; may extract unwanted compounds |

| Scalability | Highly scalable for commercial hemp oil production | Variable scalability depending on solvent type and safety protocols |

Introduction to Hemp Oil Extraction Methods

Supercritical CO2 extraction utilizes pressurized carbon dioxide to isolate hemp oil, producing a pure, solvent-free product with preserved cannabinoids and terpenes. Solvent extraction employs chemical solvents like ethanol or butane to dissolve hemp oil compounds but may leave residual solvents and require further purification. These methods differ in efficiency, safety, and the quality of extracted hemp oil, influencing end-product applications in wellness and medical industries.

What is Supercritical CO2 Extraction?

Supercritical CO2 extraction is a method that uses carbon dioxide at high pressure and temperature beyond its critical point to isolate hemp oil compounds efficiently. This technique ensures a solvent-free, pure, and high-quality extract by selectively targeting cannabinoids, terpenes, and flavonoids without thermal degradation. It is widely preferred for producing pharmaceutical-grade hemp oil due to its environmental safety, precision, and ability to preserve bioactive components.

Understanding Solvent Extraction Techniques

Solvent extraction techniques for hemp oil involve using chemical solvents like ethanol or butane to dissolve cannabinoids and terpenes from the plant material, offering high extraction efficiency but raising concerns about residual solvent contamination. Compared to supercritical CO2 extraction, solvent extraction can process larger volumes quickly and at lower initial equipment costs, though it requires thorough post-processing to ensure purity and safety. Understanding the solvent-to-material ratio, temperature control, and solvent recovery methods is crucial to optimize yield and preserve the bioactive compounds in hemp oil.

Key Differences Between CO2 and Solvent Extraction

Supercritical CO2 extraction utilizes pressurized carbon dioxide to isolate hemp oil, preserving cannabinoids and terpenes with high purity and minimal solvent residue. Solvent extraction employs chemicals like ethanol or hydrocarbons, which can leave trace solvents and potentially degrade sensitive compounds due to heat exposure. CO2 extraction offers superior control over temperature and pressure, resulting in a cleaner, more consistent hemp oil compared to the faster but less precise solvent methods.

Purity and Quality of Hemp Oil: CO2 vs Solvent

Supercritical CO2 extraction offers higher purity and superior quality hemp oil by avoiding chemical residues and preserving delicate cannabinoids and terpenes. Solvent extraction often leaves trace amounts of solvents like butane or ethanol, which can compromise the oil's purity and safety. The precise temperature and pressure control in CO2 extraction maintains hemp oil's natural profile and enhances its therapeutic properties.

Safety Considerations in Extraction Processes

Supercritical CO2 extraction of hemp oil offers a safer alternative by eliminating flammable solvents, reducing fire and explosion risks during processing. Solvent extraction typically involves chemicals like hexane or ethanol, which pose higher hazards due to toxicity and potential residual solvents in the final product. Ensuring operator safety and product purity, supercritical CO2 is favored in industrial hemp oil extraction for its inert, non-toxic, and environmentally benign properties.

Environmental Impact: CO2 Extraction vs Solvents

Supercritical CO2 extraction offers a cleaner environmental footprint compared to solvent extraction, as it uses non-toxic CO2 that can be recycled, eliminating harmful chemical residues and reducing hazardous waste. In contrast, solvent extraction relies on organic solvents like hexane or ethanol, which pose risks of air and water pollution, and require careful disposal to prevent ecosystem contamination. The energy efficiency and closed-loop design of CO2 extraction systems further minimize carbon emissions, supporting sustainable hemp oil production.

Efficiency and Yield Comparison

Supercritical CO2 extraction offers higher efficiency and cleaner yields in hemp oil production compared to solvent extraction, preserving the oil's terpene and cannabinoid profiles more effectively. This method enables precise temperature and pressure control, resulting in a purer extract free from residual solvents often found in solvent-based processes. While solvent extraction can be faster, it typically produces lower quality oil with potential contaminants, making CO2 extraction the preferred technique for maximizing yield and product integrity in the hemp industry.

Cost Analysis of Extraction Methods

Supercritical CO2 extraction of hemp oil involves higher initial capital investment due to the cost of specialized equipment, but it offers lower operational costs by eliminating solvent purchases and reducing post-extraction processing. Solvent extraction presents lower upfront expenses but incurs continual costs for solvents such as ethanol or hydrocarbons and requires additional purification steps to remove residues. Over time, CO2 extraction tends to be more cost-effective and environmentally sustainable, with increased yield purity justifying the higher initial expenditure.

Which Extraction Method is Best for Hemp Oil?

Supercritical CO2 extraction is the preferred method for hemp oil due to its ability to preserve cannabinoids and terpenes without leaving harmful residues, ensuring a pure and high-quality product. Solvent extraction, while cost-effective, often uses chemical solvents like ethanol or butane that can compromise oil purity and safety. The superior selectivity and environmental friendliness of supercritical CO2 make it the best extraction method for producing premium hemp oil.

Supercritical CO2 Extraction vs Solvent Extraction (Hemp oil) Infographic

materialdif.com

materialdif.com