Combed hemp fibers undergo an additional process to remove shorter strands and impurities, resulting in a smoother, stronger, and more uniform texture ideal for high-quality textiles. Carded hemp fibers are separated and detangled but retain more natural variability, providing a coarser, bulkier material suitable for insulation, rope, and rough fabric production. Choosing between combed and carded hemp depends on the desired end-use, with combed hemp favored for softness and durability, while carded hemp is preferred for robustness and volume.

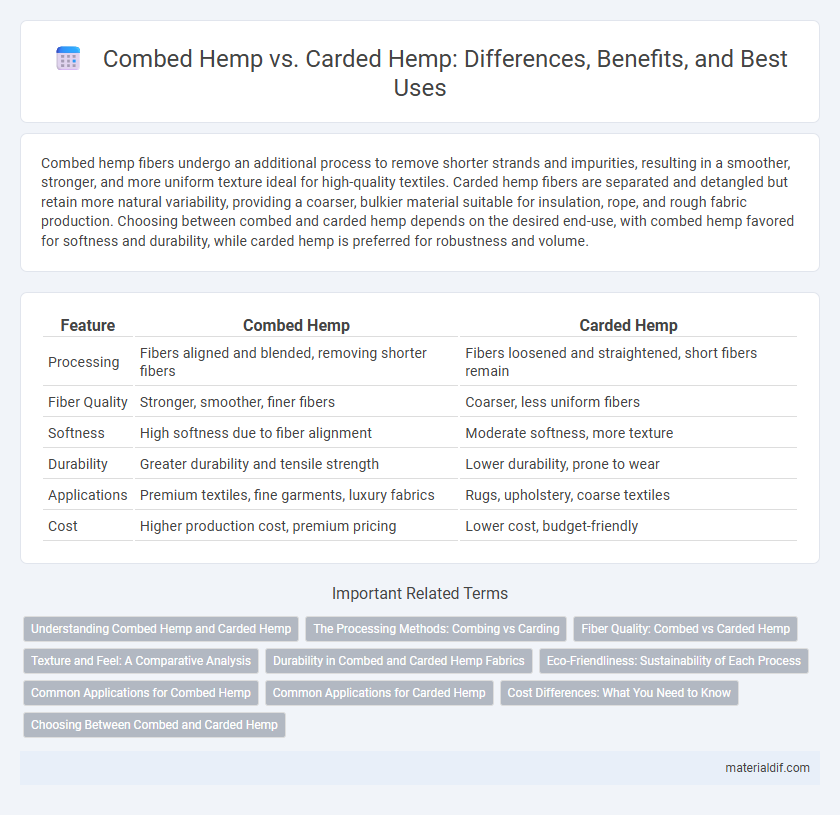

Table of Comparison

| Feature | Combed Hemp | Carded Hemp |

|---|---|---|

| Processing | Fibers aligned and blended, removing shorter fibers | Fibers loosened and straightened, short fibers remain |

| Fiber Quality | Stronger, smoother, finer fibers | Coarser, less uniform fibers |

| Softness | High softness due to fiber alignment | Moderate softness, more texture |

| Durability | Greater durability and tensile strength | Lower durability, prone to wear |

| Applications | Premium textiles, fine garments, luxury fabrics | Rugs, upholstery, coarse textiles |

| Cost | Higher production cost, premium pricing | Lower cost, budget-friendly |

Understanding Combed Hemp and Carded Hemp

Combed hemp undergoes a meticulous process that removes short fibers and impurities, resulting in a smoother, stronger, and finer material ideal for high-quality textiles. Carded hemp involves separating and aligning fibers through a carding machine, producing a coarser, more textured fiber suitable for insulation, rope, and lower-grade fabrics. Understanding these distinctions helps manufacturers select the appropriate fiber type to optimize durability, softness, and end-use performance in hemp products.

The Processing Methods: Combing vs Carding

Combed hemp undergoes a meticulous combing process that aligns fibers parallel, removing short and tangled strands to produce smoother, stronger yarn ideal for fine textiles. Carded hemp is processed using carding machines that disentangle and separate fibers into a fluffy web, resulting in a coarser texture suited for insulation, paper, and rougher fabrics. The key difference lies in combing creating uniform fiber alignment for superior strength, while carding focuses on fiber separation without extensive alignment, affecting durability and fabric feel.

Fiber Quality: Combed vs Carded Hemp

Combed hemp fibers are aligned and refined by removing shorter strands and impurities, resulting in smoother, stronger, and more uniform fibers ideal for high-quality textiles. Carded hemp retains a greater amount of shorter fibers and natural debris, producing a coarser texture with less tensile strength suited for insulation and rougher fabric applications. The combing process enhances fiber quality by increasing fiber length and consistency, whereas carding maintains the raw fiber's bulk and texture.

Texture and Feel: A Comparative Analysis

Combed hemp fibers undergo an extra processing step that removes impurities and short fibers, resulting in a smoother, finer texture with increased softness compared to carded hemp. Carded hemp retains more of its natural roughness and coarser feel due to the less intensive fiber alignment process. This difference in texture and feel makes combed hemp preferable for high-quality textiles requiring a softer touch, while carded hemp suits more durable, rustic applications.

Durability in Combed and Carded Hemp Fabrics

Combed hemp fabric undergoes a thorough process removing short fibers and impurities, resulting in smoother, stronger, and more durable textile ideal for long-lasting garments. Carded hemp fabric retains more short fibers, providing a coarser texture but lower tensile strength and durability compared to combed hemp. The enhanced fiber alignment in combed hemp significantly improves wear resistance and fabric longevity, making it superior for heavy-use applications.

Eco-Friendliness: Sustainability of Each Process

Combed hemp involves aligning fibers by removing shorter strands through a mechanical process, resulting in smoother, stronger yarns with less waste, enhancing sustainability by extending fabric durability. Carded hemp requires less energy and water but produces a rougher texture with shorter fibers, leading to quicker degradation and potential need for replacement, which may increase environmental impact over time. Both methods offer eco-friendly benefits, but combed hemp's durability and reduced waste make it a more sustainable choice in sustainable textile production.

Common Applications for Combed Hemp

Combed hemp fibers, known for their smoothness and strength, are commonly used in high-quality textiles such as clothing, upholstery, and fine fabric blends. The combing process removes shorter fibers and impurities, resulting in a softer, more uniform yarn ideal for garments requiring durability and comfort. These properties also make combed hemp suitable for eco-friendly fashion and sustainable home decor products.

Common Applications for Carded Hemp

Carded hemp fibers are commonly used in applications such as insulation materials, composite panels, and low-strength textiles due to their naturally coarse texture and shorter fiber length. These fibers provide cost-effective reinforcement in building materials and are ideal for environmentally sustainable construction products. Carded hemp is also utilized in paper production and non-woven fabrics where durability and bulk are prioritized over fine quality.

Cost Differences: What You Need to Know

Combed hemp undergoes a more intensive processing method that removes shorter fibers to create a smoother, finer end product, resulting in higher production costs compared to carded hemp, which retains more fiber impurities and requires less processing. The cost difference between combed and carded hemp typically reflects the quality and strength of the material, with combed hemp priced significantly higher due to its enhanced softness and durability. Businesses and consumers should weigh these cost differences against the specific application requirements and budget constraints when choosing between combed and carded hemp fibers.

Choosing Between Combed and Carded Hemp

Choosing between combed hemp and carded hemp depends on the desired fabric quality and application. Combed hemp fibers undergo an extra process to remove short fibers and impurities, resulting in a smoother, stronger, and more durable textile ideal for premium clothing and upholstery. Carded hemp retains more of the natural fiber length and texture, offering a coarser, bulkier fabric that is suitable for insulation, ropes, and eco-friendly packaging materials.

Combed Hemp vs Carded Hemp Infographic

materialdif.com

materialdif.com