Wet retting involves submerging hemp stalks in water to promote microbial activity that breaks down pectin, resulting in softer fibers with higher tensile strength. Dry retting relies on natural moisture and air exposure to degrade the stalks, producing coarser fibers with lower yields but reduced processing costs. Choosing between wet and dry retting impacts fiber quality and environmental footprint in hemp production.

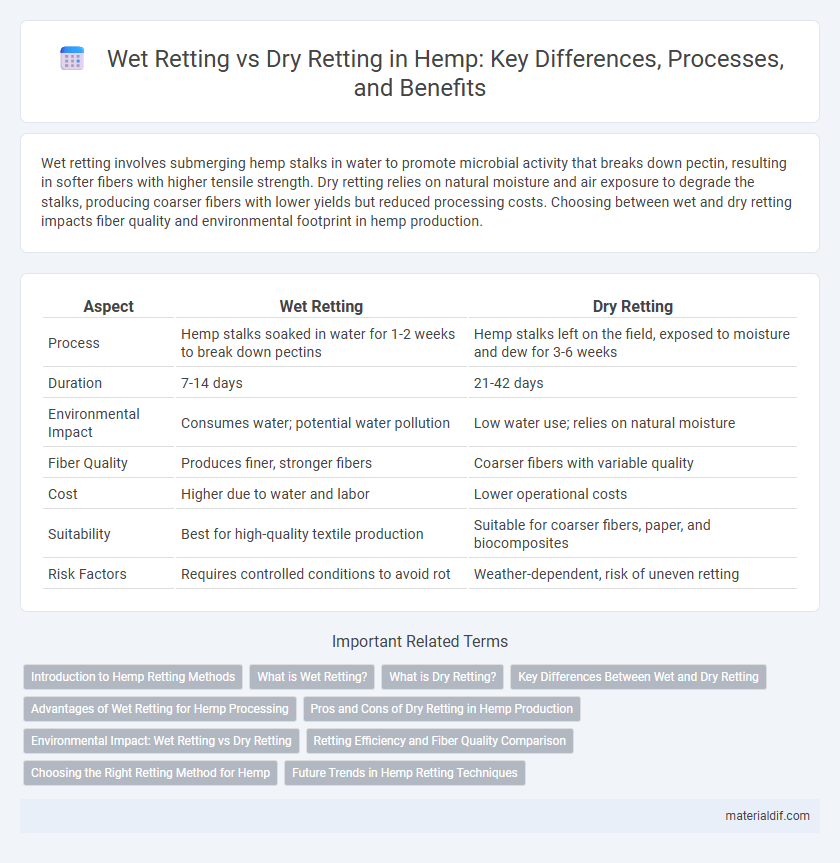

Table of Comparison

| Aspect | Wet Retting | Dry Retting |

|---|---|---|

| Process | Hemp stalks soaked in water for 1-2 weeks to break down pectins | Hemp stalks left on the field, exposed to moisture and dew for 3-6 weeks |

| Duration | 7-14 days | 21-42 days |

| Environmental Impact | Consumes water; potential water pollution | Low water use; relies on natural moisture |

| Fiber Quality | Produces finer, stronger fibers | Coarser fibers with variable quality |

| Cost | Higher due to water and labor | Lower operational costs |

| Suitability | Best for high-quality textile production | Suitable for coarser fibers, paper, and biocomposites |

| Risk Factors | Requires controlled conditions to avoid rot | Weather-dependent, risk of uneven retting |

Introduction to Hemp Retting Methods

Wet retting and dry retting are two primary methods used to extract fibers from hemp stalks, each influencing fiber quality and processing time. Wet retting involves submerging hemp stalks in water to encourage microbial activity that breaks down the pectin binding fibers, resulting in finer, softer fibers but requiring substantial water and time. Dry retting relies on natural environmental conditions like dew and air moisture, producing coarser fibers with less resource usage but often resulting in less uniform quality.

What is Wet Retting?

Wet retting is a traditional hemp processing method that uses water to separate the fiber from the stalk by promoting microbial activity. The hemp stalks are submerged in ponds or tanks for several days, allowing microorganisms to break down the pectin that binds the fibers. This process results in high-quality, long fibers ideal for textiles and rope production.

What is Dry Retting?

Dry retting is a natural process used to separate hemp fibers by allowing the stalks to dry in the field for several weeks, promoting microbial activity that breaks down pectins binding the fibers to the woody core. This method reduces moisture-related issues and produces higher-quality fibers with less risk of mold compared to wet retting. Dry retting is preferred for producing fine, long hemp fibers suitable for textiles and composites.

Key Differences Between Wet and Dry Retting

Wet retting involves submerging hemp stalks in water, promoting microbial activity that breaks down pectins, resulting in faster fiber separation but higher water usage and potential environmental concerns. Dry retting relies on natural dew, humidity, and microbial contact in open air to degrade pectins more slowly, producing softer fibers with less environmental impact but requiring more time and careful monitoring. The key differences between wet and dry retting include processing time, water consumption, fiber quality, and ecological footprint.

Advantages of Wet Retting for Hemp Processing

Wet retting enhances hemp fiber quality by promoting controlled microbial activity that efficiently breaks down pectin, resulting in softer, stronger fibers ideal for textiles. This method reduces dust and airborne pollution compared to dry retting, improving worker safety and environmental conditions. Furthermore, wet retting accelerates the processing time, leading to higher yield and consistency in fiber extraction.

Pros and Cons of Dry Retting in Hemp Production

Dry retting in hemp production offers advantages such as reduced water usage and lower risk of fiber contamination compared to wet retting. It results in higher fiber strength and quality but requires longer processing times and is more dependent on favorable weather conditions. The method's sensitivity to humidity and temperature fluctuations can lead to inconsistent fiber retting and potential yield loss.

Environmental Impact: Wet Retting vs Dry Retting

Wet retting of hemp involves submerging stalks in water, which often leads to water pollution due to the release of organic waste and nutrients, posing risks to aquatic ecosystems. Dry retting, relying on natural air and microbial activity, minimizes water use and reduces the risk of water contamination, making it a more environmentally sustainable method. However, dry retting may require longer processing time and is climate-dependent, influencing its efficiency and scalability.

Retting Efficiency and Fiber Quality Comparison

Wet retting of hemp involves submerging stalks in water, promoting microbial activity that efficiently separates fibers with high cellulose retention, resulting in finer, softer fibers ideal for textile applications. Dry retting, relying on natural dew and microbial action in open air, yields coarser fibers with lower fiber yield and more impurities, which may require additional processing but preserves certain lignin components enhancing fiber rigidity. Comparing retting efficiency, wet retting offers faster and more uniform fiber extraction, while fiber quality assessment shows wet-retted hemp fibers generally exhibit superior tensile strength and smoother texture compared to the rougher, less consistent fibers from dry retting.

Choosing the Right Retting Method for Hemp

Wet retting involves submerging hemp stalks in water to facilitate microbial breakdown of pectin, resulting in softer fibers with higher tensile strength but longer processing times and greater water usage. Dry retting relies on natural moisture and microbial action in ambient air, producing coarser fibers with lower water consumption and faster processing but potentially less uniform fiber quality. Selecting the proper retting method depends on factors such as desired fiber characteristics, environmental impact, available resources, and processing scale.

Future Trends in Hemp Retting Techniques

Emerging hemp retting techniques emphasize eco-friendly, efficient processes such as enzymatic retting and microbial fermentation, which reduce water usage compared to traditional wet retting. Innovations in controlled dry retting and hybrid methods aim to enhance fiber quality while minimizing environmental impact. Future trends prioritize sustainable practices and scalable solutions to meet the growing demand for high-quality hemp fibers in textiles and biocomposites.

Wet retting vs dry retting Infographic

materialdif.com

materialdif.com