Wet spun hemp fibers are produced by extruding hemp cellulose into a coagulation bath, resulting in finer, stronger, and more uniform fibers ideal for textiles requiring smoothness and durability. Dry spun hemp fibers are created by drying the extruded fibers with hot air, producing coarser, less uniform strands often used for heavier fabrics and ropes due to their rough texture. The choice between wet spun and dry spun hemp impacts the fabric's strength, softness, and application, with wet spinning offering higher quality for premium textile products.

Table of Comparison

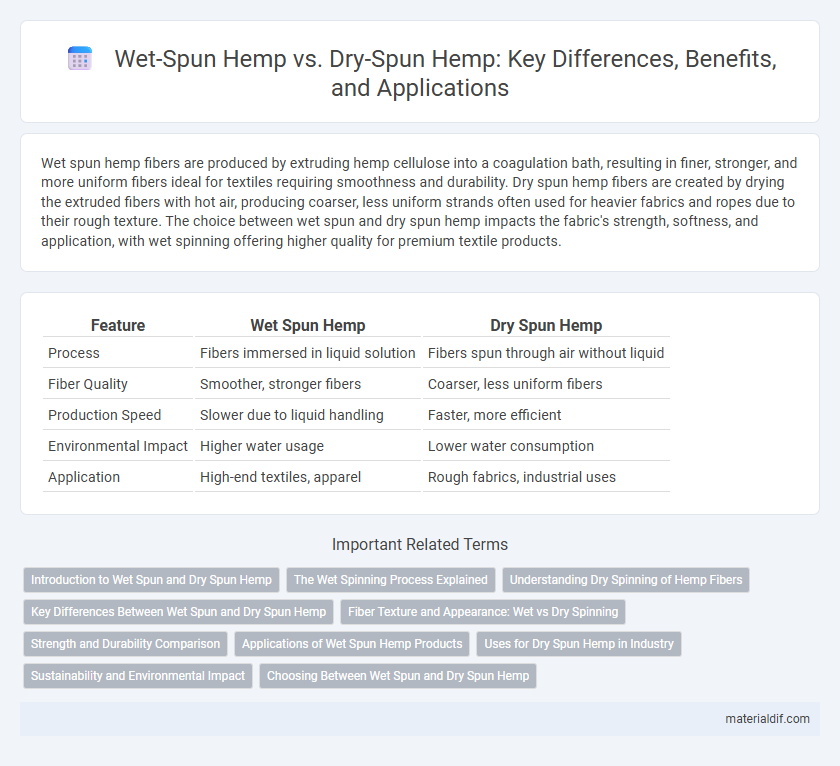

| Feature | Wet Spun Hemp | Dry Spun Hemp |

|---|---|---|

| Process | Fibers immersed in liquid solution | Fibers spun through air without liquid |

| Fiber Quality | Smoother, stronger fibers | Coarser, less uniform fibers |

| Production Speed | Slower due to liquid handling | Faster, more efficient |

| Environmental Impact | Higher water usage | Lower water consumption |

| Application | High-end textiles, apparel | Rough fabrics, industrial uses |

Introduction to Wet Spun and Dry Spun Hemp

Wet spun hemp fibers are produced by extruding hemp cellulose through a liquid bath, resulting in smoother, finer, and stronger fibers ideal for high-quality textiles. Dry spun hemp involves spinning the fibers without a liquid medium, yielding coarser yarn suitable for more durable uses like ropes and industrial fabrics. Each method impacts fiber texture, strength, and end-use applications in hemp product manufacturing.

The Wet Spinning Process Explained

The wet spinning process for hemp involves dissolving hemp fibers in a chemical solution to create a viscous liquid, which is then extruded through spinnerets into a coagulation bath, solidifying the fibers into continuous filaments. This method enhances fiber strength, softness, and uniformity compared to dry spinning, making it ideal for high-quality textile production. Wet spun hemp fibers exhibit superior moisture absorption and dyeability, contributing to their preference in luxury fabric manufacturing.

Understanding Dry Spinning of Hemp Fibers

Dry spinning of hemp fibers involves processing fibers without the use of water, preserving their natural strength and flexibility. This method produces softer and more durable textiles compared to wet spun hemp, which undergoes water treatment that can weaken fibers. Dry spun hemp is ideal for lightweight, breathable fabrics used in eco-friendly fashion and industrial applications.

Key Differences Between Wet Spun and Dry Spun Hemp

Wet spun hemp fibers are produced by extruding hemp cellulose through a liquid bath, resulting in stronger, finer, and more uniform fibers with enhanced tensile strength and flexibility. Dry spun hemp fibers are created by evaporating solvents from the spun solution, leading to coarser, less uniform fibers that often require additional processing for strength and softness. The key differences lie in fiber morphology, strength, and applications, with wet spun hemp favored for textiles requiring high durability and dry spun hemp used in composites and industrial materials.

Fiber Texture and Appearance: Wet vs Dry Spinning

Wet spun hemp fibers exhibit a smoother texture and finer appearance due to the fiber's immersion in water during processing, which helps align cellulose molecules and remove impurities. Dry spun hemp fibers tend to have a coarser, stiffer texture with a more irregular surface, as the absence of water limits fiber alignment and results in retained lignin and pectin. These differences in fiber texture and appearance significantly affect the suitability of wet spun hemp for high-quality textiles and dry spun hemp for more durable, rustic applications.

Strength and Durability Comparison

Wet spun hemp fibers exhibit greater strength and durability compared to dry spun hemp due to the enhanced fiber alignment and reduced impurities achieved during the aqueous spinning process. The wet spinning method produces smoother, finer fibers with higher tensile strength, making them ideal for industrial textiles requiring long-lasting performance. In contrast, dry spun hemp fibers tend to be coarser and less uniform, resulting in lower overall durability and mechanical properties.

Applications of Wet Spun Hemp Products

Wet spun hemp fibers exhibit superior softness, strength, and uniformity, making them ideal for high-end textiles such as luxury apparel, fine linens, and delicate upholstery fabrics. These fibers offer enhanced moisture absorption and breathability, which benefit performance sportswear and medical textiles requiring comfort and durability. Wet spun hemp's refined texture supports advanced composite materials in automotive and aerospace industries, providing lightweight reinforcement with sustainable properties.

Uses for Dry Spun Hemp in Industry

Dry spun hemp fibers offer superior strength and durability, making them ideal for industrial applications such as textiles, automotive composites, and construction materials. Their rough texture enhances adhesion in biocomposites used for eco-friendly automotive panels and insulation products. Industries leverage dry spun hemp for its moisture resistance and structural integrity, contributing to sustainable manufacturing processes.

Sustainability and Environmental Impact

Wet spun hemp fibers demonstrate superior sustainability due to reduced chemical usage and lower energy consumption compared to dry spun hemp, which demands more intensive mechanical processing. The wet spinning process minimizes environmental pollution by enabling the recycling of water and solvents, resulting in a smaller ecological footprint. In contrast, dry spun hemp often generates more waste and emissions, making it less favorable in eco-friendly textile production.

Choosing Between Wet Spun and Dry Spun Hemp

Wet spun hemp fibers offer superior strength, softness, and uniformity due to the fiber extraction process in water, making them ideal for high-quality textiles and sensitive applications. Dry spun hemp, extracted mechanically without water, retains more natural hemp characteristics and offers a more eco-friendly and cost-effective option with a coarser texture suitable for industrial fabrics and composites. Choosing between wet spun and dry spun hemp depends on balancing the desired fiber quality, environmental impact, and end-use requirements.

Wet spun hemp vs Dry spun hemp Infographic

materialdif.com

materialdif.com