Thermoplastic hemp composites offer enhanced recyclability and flexibility due to their ability to be melted and reshaped multiple times, making them ideal for sustainable manufacturing. In contrast, thermoset hemp composites provide superior heat resistance and structural integrity by forming irreversible chemical bonds during curing, suited for high-strength and durable applications. Choosing between thermoplastic and thermoset hemp depends on the specific performance requirements and environmental considerations of the end-use product.

Table of Comparison

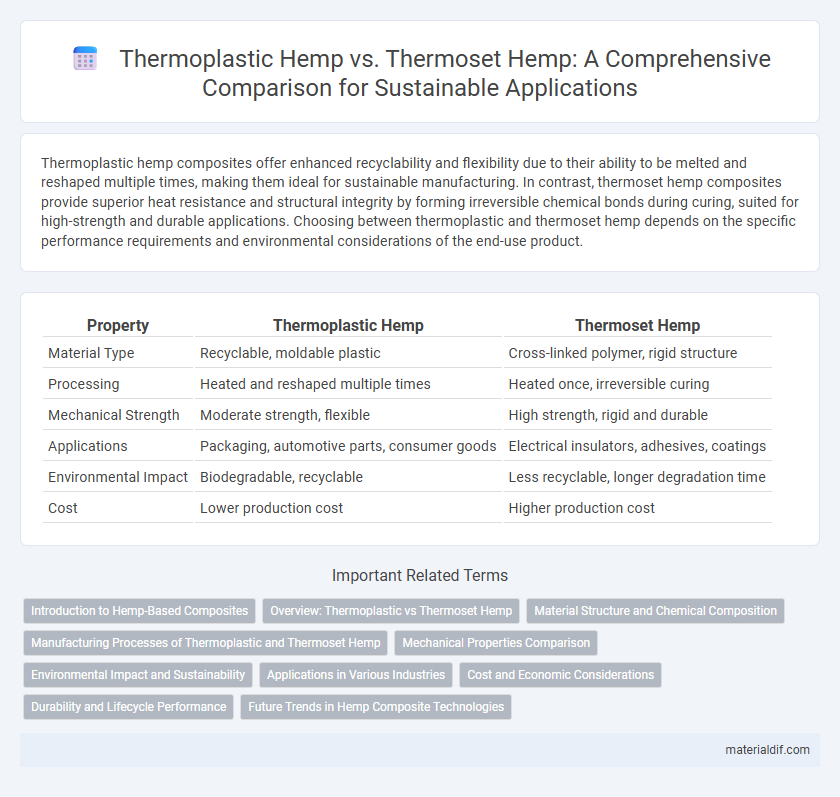

| Property | Thermoplastic Hemp | Thermoset Hemp |

|---|---|---|

| Material Type | Recyclable, moldable plastic | Cross-linked polymer, rigid structure |

| Processing | Heated and reshaped multiple times | Heated once, irreversible curing |

| Mechanical Strength | Moderate strength, flexible | High strength, rigid and durable |

| Applications | Packaging, automotive parts, consumer goods | Electrical insulators, adhesives, coatings |

| Environmental Impact | Biodegradable, recyclable | Less recyclable, longer degradation time |

| Cost | Lower production cost | Higher production cost |

Introduction to Hemp-Based Composites

Hemp-based composites utilize fibers derived from the hemp plant to reinforce polymer matrices, offering sustainable alternatives to conventional materials. Thermoplastic hemp composites, composed of hemp fibers combined with polymers that soften upon heating, provide recyclability and impact resistance, making them suitable for automotive and packaging applications. In contrast, thermoset hemp composites involve hemp fibers embedded in polymers that irreversibly cure, delivering superior mechanical strength and thermal stability for use in construction and aerospace industries.

Overview: Thermoplastic vs Thermoset Hemp

Thermoplastic hemp composites soften when heated and can be reshaped multiple times, offering recyclability and ease of processing, making them suitable for automotive and packaging applications. Thermoset hemp composites undergo a curing process that creates a rigid, heat-resistant structure, ideal for high-strength and durable uses in construction and aerospace industries. The choice between thermoplastic and thermoset hemp depends on factors such as mechanical performance, processing methods, and end-use requirements.

Material Structure and Chemical Composition

Thermoplastic hemp composites consist of hemp fibers embedded in a polymer matrix that softens upon heating, typically consisting of polyethylene or polypropylene, allowing for reshaping and recycling. Thermoset hemp composites involve hemp fibers combined with polymers like epoxy or polyester resins that undergo irreversible curing, creating a rigid, cross-linked network with enhanced mechanical strength and thermal resistance. The primary chemical distinction lies in thermoplastics having linear or branched polymer chains without cross-linking, while thermosets possess densely cross-linked polymers, influencing their material structure and performance characteristics.

Manufacturing Processes of Thermoplastic and Thermoset Hemp

Thermoplastic hemp composites are manufactured through processes like injection molding and extrusion, where the material softens upon heating and solidifies upon cooling, allowing for easy reshaping and recycling. Thermoset hemp composites involve curing reactions during manufacturing, such as compression molding or resin infusion, resulting in a rigid, cross-linked polymer structure that cannot be remelted or reprocessed. The choice between thermoplastic and thermoset hemp manufacturing impacts product durability, recyclability, and production cycle times.

Mechanical Properties Comparison

Thermoplastic hemp composites exhibit higher impact resistance and greater flexibility due to their ability to undergo reversible melting, making them ideal for applications requiring toughness and durability. Thermoset hemp composites demonstrate superior mechanical strength, stiffness, and thermal stability because of their cross-linked polymer matrix, resulting in enhanced load-bearing capacity. The selection between thermoplastic and thermoset hemp materials depends on the specific mechanical property requirements such as impact tolerance, rigidity, and thermal resistance in industrial applications.

Environmental Impact and Sustainability

Thermoplastic hemp composites exhibit superior recyclability and lower greenhouse gas emissions compared to thermoset hemp, which typically relies on non-recyclable resins leading to landfill accumulation. The biodegradable nature of thermoplastic matrices combined with hemp's carbon sequestration capacity significantly enhances sustainability profiles. Life cycle assessments reveal thermoplastic hemp reduces environmental impact through energy-efficient processing and potential for material recovery, positioning it as a greener alternative in biocomposite applications.

Applications in Various Industries

Thermoplastic hemp composites offer flexibility and recyclability, making them ideal for automotive components, packaging, and consumer goods that require impact resistance and lightweight properties. Thermoset hemp materials provide excellent thermal stability and mechanical strength, suited for construction panels, electrical enclosures, and high-performance sporting equipment. The choice between thermoplastic and thermoset hemp depends on industry-specific requirements such as durability, environmental impact, and end-use functionality.

Cost and Economic Considerations

Thermoplastic hemp composites generally offer lower production costs due to their recyclability and shorter processing times compared to thermoset hemp composites, which require more energy-intensive curing processes and specialized handling. The economic advantage of thermoplastic hemp lies in its potential for mass production and reduced waste management costs, making it more viable for large-scale applications. Conversely, thermoset hemp composites, while often providing superior mechanical properties, involve higher initial investment and disposal expenses, limiting their cost-effectiveness in budget-sensitive projects.

Durability and Lifecycle Performance

Thermoplastic hemp composites offer enhanced durability due to their ability to withstand repeated heating and reshaping without significant degradation, providing a longer lifecycle performance in applications requiring flexibility. Thermoset hemp composites, cured through irreversible chemical bonding, deliver superior mechanical strength and thermal stability but exhibit limited recyclability and shorter lifecycle due to brittleness over time. Optimizing the selection between thermoplastic and thermoset hemp depends on balancing durability needs with environmental impact and end-of-life processing requirements.

Future Trends in Hemp Composite Technologies

Thermoplastic hemp composites exhibit superior recyclability and faster processing times compared to thermoset hemp composites, driving future industry adoption. Advances in bio-based thermoplastic matrices and nanocellulose reinforcement are enhancing mechanical properties and sustainability of hemp composites. Increasing demand for lightweight, eco-friendly automotive and construction materials fuels innovation in thermoplastic hemp composite technologies.

Thermoplastic hemp vs Thermoset hemp Infographic

materialdif.com

materialdif.com