Raw gypsum is a naturally occurring mineral primarily composed of calcium sulfate dihydrate, extracted from sedimentary deposits. Synthetic gypsum is a byproduct of industrial processes, such as flue gas desulfurization in power plants, offering a chemically similar but often purer alternative. Both types serve critical roles in construction and agriculture, with synthetic gypsum promoting sustainable resource recycling and reducing environmental impact.

Table of Comparison

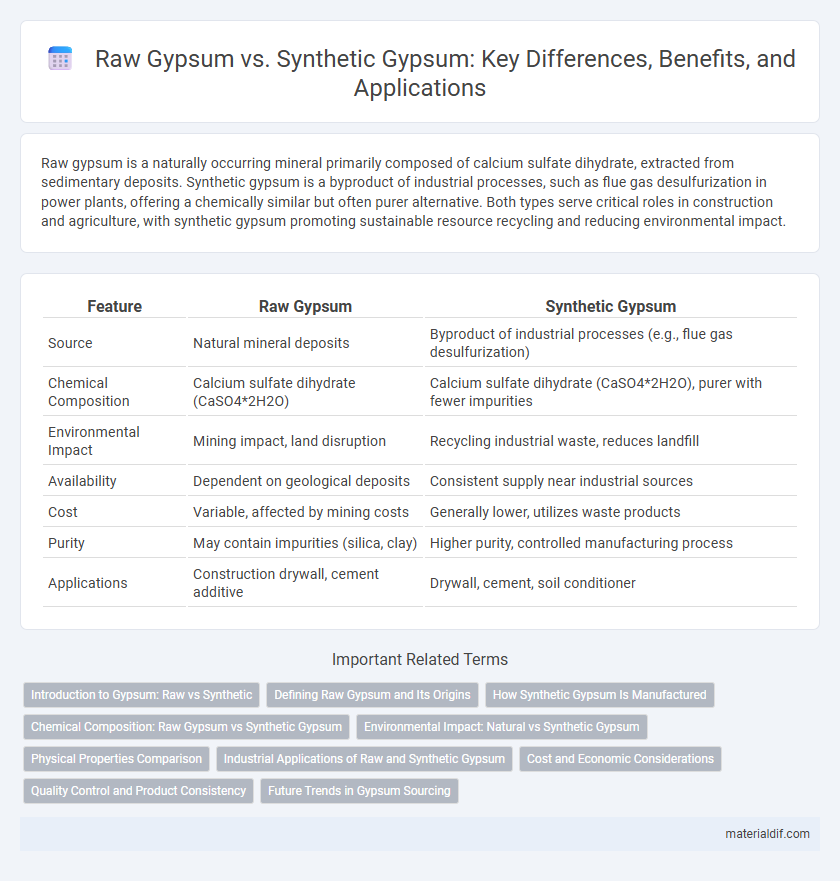

| Feature | Raw Gypsum | Synthetic Gypsum |

|---|---|---|

| Source | Natural mineral deposits | Byproduct of industrial processes (e.g., flue gas desulfurization) |

| Chemical Composition | Calcium sulfate dihydrate (CaSO4*2H2O) | Calcium sulfate dihydrate (CaSO4*2H2O), purer with fewer impurities |

| Environmental Impact | Mining impact, land disruption | Recycling industrial waste, reduces landfill |

| Availability | Dependent on geological deposits | Consistent supply near industrial sources |

| Cost | Variable, affected by mining costs | Generally lower, utilizes waste products |

| Purity | May contain impurities (silica, clay) | Higher purity, controlled manufacturing process |

| Applications | Construction drywall, cement additive | Drywall, cement, soil conditioner |

Introduction to Gypsum: Raw vs Synthetic

Raw gypsum, a naturally occurring mineral primarily composed of calcium sulfate dihydrate, is extracted through mining and used extensively in construction and agriculture. Synthetic gypsum, generated as a byproduct from industrial processes such as flue gas desulfurization in power plants, offers a high-purity alternative with consistent chemical properties. The distinction between raw and synthetic gypsum affects material performance, environmental impact, and resource availability in various industrial applications.

Defining Raw Gypsum and Its Origins

Raw gypsum is a natural mineral composed primarily of calcium sulfate dihydrate, formed through geological processes such as the evaporation of ancient seawater. It is typically extracted from sedimentary rock formations in open-pit or underground mining operations. The mineral's purity and composition vary depending on the geographical source and environmental conditions during its formation, distinguishing it from synthetic gypsum produced through industrial byproducts.

How Synthetic Gypsum Is Manufactured

Synthetic gypsum is manufactured through the flue gas desulfurization (FGD) process in coal-fired power plants, where sulfur dioxide (SO2) emissions react with lime or limestone slurry to produce calcium sulfate dihydrate (CaSO4*2H2O). This controlled chemical reaction yields a byproduct nearly identical in purity and composition to natural raw gypsum, allowing for its use in construction materials like drywall. The production of synthetic gypsum reduces environmental pollutants while recycling industrial waste into valuable construction inputs.

Chemical Composition: Raw Gypsum vs Synthetic Gypsum

Raw gypsum primarily consists of calcium sulfate dihydrate (CaSO4*2H2O) with natural impurities such as clay, sand, and organic matter affecting its purity and chemical consistency. Synthetic gypsum, produced from industrial processes like flue gas desulfurization, maintains a higher purity level of calcium sulfate dihydrate with significantly lower impurity levels and enhanced uniformity in chemical composition. The controlled manufacturing of synthetic gypsum results in a more consistent chemical profile, making it preferable for applications requiring precise material specifications.

Environmental Impact: Natural vs Synthetic Gypsum

Natural gypsum extraction leads to habitat disruption, soil erosion, and significant mining waste, negatively impacting local ecosystems. Synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization, reduces landfill waste and lowers the carbon footprint associated with gypsum production. The use of synthetic gypsum supports sustainable practices by minimizing resource depletion and promoting circular economy principles in construction materials.

Physical Properties Comparison

Raw gypsum typically contains impurities like clay, sand, and organic matter, resulting in variable color ranging from white to gray and a slightly lower purity of calcium sulfate dihydrate (CaSO4*2H2O). Synthetic gypsum, often produced from flue gas desulfurization (FGD) processes, presents a more consistent white color and higher purity levels, usually exceeding 95% CaSO4*2H2O, enhancing its reactivity and crystal structure uniformity. The finer particle size and lower moisture content in synthetic gypsum improve its handling, solubility, and setting times when used in manufacturing applications such as drywall and cement.

Industrial Applications of Raw and Synthetic Gypsum

Raw gypsum is extensively used in the construction industry for manufacturing drywall, plaster, and cement due to its natural abundance and cost-effectiveness. Synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization, offers higher purity and consistency, making it ideal for high-quality plasterboard and agricultural soil amendments. Both types play crucial roles in cement production and environmental management by recycling industrial waste into valuable building materials.

Cost and Economic Considerations

Raw gypsum, extracted from natural mineral deposits, typically involves higher mining and transportation costs, influencing overall project expenses. Synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization, often reduces raw material costs and supports waste recycling initiatives, enhancing economic efficiency. The choice between raw and synthetic gypsum depends on availability, purity requirements, and regulatory incentives that impact cost-effectiveness and sustainability in construction and manufacturing industries.

Quality Control and Product Consistency

Raw gypsum quality varies due to impurities like clay, sand, and moisture, impacting product consistency and requiring extensive purification during processing. Synthetic gypsum, derived from flue gas desulfurization, offers superior quality control with minimal impurities and a more uniform chemical composition, resulting in consistent performance for construction materials. The controlled production environment of synthetic gypsum ensures standardized particle size and purity, enhancing durability and strength in finished products compared to natural gypsum.

Future Trends in Gypsum Sourcing

Raw gypsum, primarily extracted through mining, faces challenges such as depletion of high-purity reserves and increasing environmental regulations, prompting industries to explore alternative sources. Synthetic gypsum, produced as a byproduct of flue gas desulfurization in power plants, is gaining traction for its consistent quality and lower ecological impact. Future trends indicate a growing reliance on synthetic gypsum driven by sustainability goals, circular economy practices, and advancements in processing technologies enhancing material efficiency and reducing carbon footprints.

Raw gypsum vs Synthetic gypsum Infographic

materialdif.com

materialdif.com