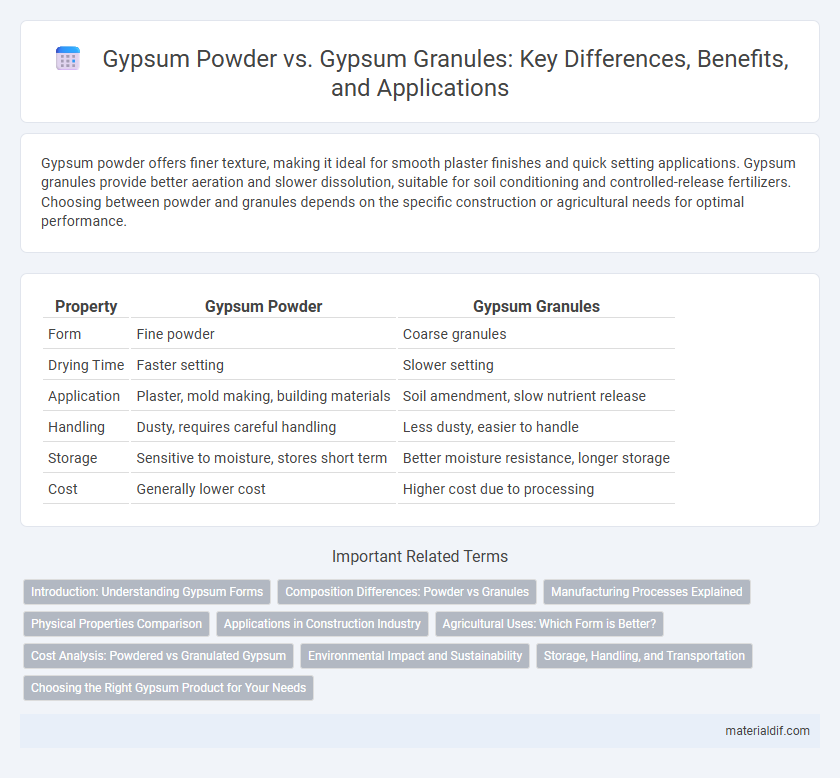

Gypsum powder offers finer texture, making it ideal for smooth plaster finishes and quick setting applications. Gypsum granules provide better aeration and slower dissolution, suitable for soil conditioning and controlled-release fertilizers. Choosing between powder and granules depends on the specific construction or agricultural needs for optimal performance.

Table of Comparison

| Property | Gypsum Powder | Gypsum Granules |

|---|---|---|

| Form | Fine powder | Coarse granules |

| Drying Time | Faster setting | Slower setting |

| Application | Plaster, mold making, building materials | Soil amendment, slow nutrient release |

| Handling | Dusty, requires careful handling | Less dusty, easier to handle |

| Storage | Sensitive to moisture, stores short term | Better moisture resistance, longer storage |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction: Understanding Gypsum Forms

Gypsum powder consists of finely ground particles primarily used in construction for plaster and drywall applications, offering quick setting times and smooth finishes. Gypsum granules are larger, coarser particles commonly employed in agriculture as soil conditioners, improving aeration and moisture retention. Each form exhibits distinct physical properties and usage benefits tailored to specific industrial and agricultural needs.

Composition Differences: Powder vs Granules

Gypsum powder consists primarily of finely ground calcium sulfate dihydrate (CaSO4*2H2O), offering a uniform particle size that facilitates rapid hydration and ease of mixing in construction applications. In contrast, gypsum granules feature larger, coarser particles with a similar chemical composition but reduced surface area, resulting in slower dissolution and extended setting times. These composition differences impact their suitability for specific uses, with powder favored for quick-setting plasters and granules preferred for long-lasting soil amendments.

Manufacturing Processes Explained

Gypsum powder is produced by grinding natural gypsum into a fine, smooth consistency after calcination, which involves heating the raw material to remove moisture and achieve a chemically stable form. Gypsum granules are created through pelletizing or agglomeration, where the powdered gypsum is moistened and formed into coarse particles or pellets, enhancing flowability and reducing dust during handling. Differences in manufacturing processes impact the end-use applications, with powder favored for plaster and cement additives and granules preferred for soil conditioning and industrial uses.

Physical Properties Comparison

Gypsum powder exhibits a finer particle size, leading to faster hydration and setting times compared to gypsum granules, which have larger, coarser particles resulting in slower water absorption and prolonged curing. The bulk density of gypsum powder is higher due to its compact particle arrangement, while gypsum granules display greater porosity, enhancing aeration but reducing density. Both forms maintain similar chemical composition, yet their distinct physical properties influence application techniques and structural performance in construction.

Applications in Construction Industry

Gypsum powder is widely used in the construction industry for manufacturing plaster, drywall, and ceiling boards due to its fine texture and ease of application. Gypsum granules, on the other hand, are primarily utilized as a soil conditioner in construction landscaping and for controlled release in cement additives to improve setting time. Both forms contribute to enhanced building durability and fire resistance, but gypsum powder remains the preferred choice for surface finishing and interior applications.

Agricultural Uses: Which Form is Better?

Gypsum powder dissolves more quickly in soil, making it ideal for rapid calcium and sulfur delivery to crops, improving soil structure and nutrient availability. Gypsum granules release these nutrients more slowly, offering longer-term soil conditioning but slower immediate impact. For agriculture, gypsum powder is generally better for quick soil pH adjustment and nutrient supplementation, while granules suit gradual soil improvement and sustained calcium supply.

Cost Analysis: Powdered vs Granulated Gypsum

Powdered gypsum generally costs less per unit due to lower processing requirements and ease of packaging, making it a budget-friendly choice for large-scale agricultural use. Granulated gypsum involves additional production steps like granulation and drying, leading to higher manufacturing expenses but offering improved handling, reduced dust, and slower nutrient release. Evaluating total cost-effectiveness depends on application scale, transportation logistics, and desired release rates, where powdered gypsum favors cost efficiency and granulated gypsum supports convenience and controlled nutrient delivery.

Environmental Impact and Sustainability

Gypsum powder and gypsum granules differ significantly in their environmental impact and sustainability profiles. Gypsum powder, often produced by grinding natural gypsum or synthetic byproducts, requires substantial energy consumption and generates dust emissions during processing, affecting air quality. In contrast, gypsum granules typically involve less processing, reducing energy use and minimizing particulate pollution, making them a more eco-friendly option for construction and agricultural applications.

Storage, Handling, and Transportation

Gypsum powder requires moisture-proof packaging and low-humidity storage to prevent clumping and degradation, whereas gypsum granules offer enhanced resistance to moisture, allowing easier handling and longer shelf life in diverse conditions. During transportation, gypsum granules minimize dust generation and spillage compared to fine gypsum powder, reducing health hazards and material loss. Proper handling equipment for powder includes sealed conveyors and dust collectors, while granules can be moved with standard bulk materials handling systems, optimizing operational efficiency.

Choosing the Right Gypsum Product for Your Needs

Gypsum powder offers a fine texture ideal for smooth plaster finishes and quicker setting times, while gypsum granules provide better aeration and slower hydration suitable for soil amendment and agricultural applications. Selecting the right gypsum product depends on the specific use case, with powder preferred for construction and granules favored in farming for improved soil structure. Understanding application requirements ensures optimal performance and cost-effectiveness in both industrial and agricultural scenarios.

Gypsum powder vs Gypsum granules Infographic

materialdif.com

materialdif.com