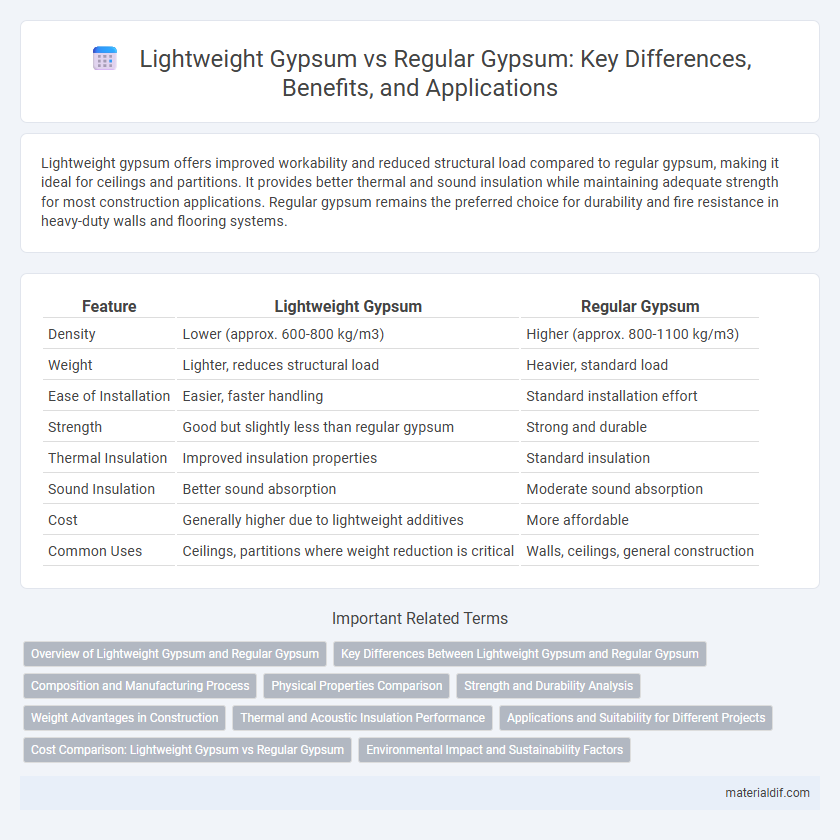

Lightweight gypsum offers improved workability and reduced structural load compared to regular gypsum, making it ideal for ceilings and partitions. It provides better thermal and sound insulation while maintaining adequate strength for most construction applications. Regular gypsum remains the preferred choice for durability and fire resistance in heavy-duty walls and flooring systems.

Table of Comparison

| Feature | Lightweight Gypsum | Regular Gypsum |

|---|---|---|

| Density | Lower (approx. 600-800 kg/m3) | Higher (approx. 800-1100 kg/m3) |

| Weight | Lighter, reduces structural load | Heavier, standard load |

| Ease of Installation | Easier, faster handling | Standard installation effort |

| Strength | Good but slightly less than regular gypsum | Strong and durable |

| Thermal Insulation | Improved insulation properties | Standard insulation |

| Sound Insulation | Better sound absorption | Moderate sound absorption |

| Cost | Generally higher due to lightweight additives | More affordable |

| Common Uses | Ceilings, partitions where weight reduction is critical | Walls, ceilings, general construction |

Overview of Lightweight Gypsum and Regular Gypsum

Lightweight gypsum contains added fillers and air pockets, making it easier to handle and install, while regular gypsum offers higher density and strength for more durable construction applications. The reduced weight of lightweight gypsum improves work efficiency and decreases overall structural load, suited for interior walls and ceiling panels. Regular gypsum's robust composition suits environments requiring enhanced sound insulation and fire resistance, commonly used in heavy-duty wall systems and exterior applications.

Key Differences Between Lightweight Gypsum and Regular Gypsum

Lightweight gypsum contains air pockets that reduce its density, making it easier to handle and install compared to regular gypsum, which is denser and offers greater durability. Regular gypsum provides better sound insulation and fire resistance, while lightweight gypsum excels in applications requiring reduced structural load. Moisture resistance varies, with regular gypsum generally performing better in humid conditions than lightweight gypsum.

Composition and Manufacturing Process

Lightweight gypsum is primarily composed of expanded perlite or vermiculite mixed with gypsum plaster, reducing its density while maintaining strength, whereas regular gypsum consists mainly of natural calcium sulfate dihydrate without additional lightweight aggregates. The manufacturing process of lightweight gypsum involves incorporating aerating agents or lightweight fillers that create air pockets, enhancing insulation and ease of handling. Regular gypsum production focuses on calcining natural gypsum ore to remove water, resulting in a denser, more rigid material ideal for structural uses.

Physical Properties Comparison

Lightweight gypsum exhibits lower density, typically ranging from 600 to 900 kg/m3, compared to regular gypsum's density of about 1,100 to 1,300 kg/m3, resulting in easier handling and reduced structural load. The compressive strength of lightweight gypsum generally falls between 2 to 4 MPa, whereas regular gypsum offers higher strength around 5 to 8 MPa, influencing its suitability for load-bearing applications. Thermal insulation properties are enhanced in lightweight gypsum due to increased porosity, offering better energy efficiency than the denser, less insulative regular gypsum.

Strength and Durability Analysis

Lightweight gypsum offers enhanced workability and easier handling compared to regular gypsum, but it generally exhibits lower compressive strength and reduced durability under high-stress conditions. Regular gypsum, with its denser composition, provides superior structural integrity and greater resistance to impact and moisture, making it ideal for load-bearing applications. Strength and durability analysis consistently shows that while lightweight gypsum is suitable for non-structural or partition walls, regular gypsum remains the preferred choice for environments demanding high strength and long-term resilience.

Weight Advantages in Construction

Lightweight gypsum offers a significant weight reduction compared to regular gypsum, typically weighing around 40-50 pounds per 4x8-foot sheet versus 60-70 pounds for standard gypsum boards. This weight advantage reduces structural load, enabling easier handling, faster installation, and lower transportation costs in construction projects. Its lighter mass also enhances seismic performance and allows for more versatile design applications in both residential and commercial buildings.

Thermal and Acoustic Insulation Performance

Lightweight gypsum offers superior thermal insulation due to its lower density and increased air pockets, which reduce heat transfer compared to regular gypsum. Acoustic insulation is also enhanced in lightweight gypsum as its porous structure absorbs sound waves more effectively, minimizing noise transmission. Regular gypsum, while denser and structurally robust, provides less efficiency in thermal and acoustic insulation applications.

Applications and Suitability for Different Projects

Lightweight gypsum is ideal for projects requiring ease of handling and quick installation, such as residential interiors and ceiling panels, due to its reduced density and enhanced thermal insulation properties. Regular gypsum, with its higher density and strength, suits applications demanding greater durability and soundproofing, including commercial walls and heavy-duty partitions. Choosing between lightweight and regular gypsum depends on specific project needs like load-bearing capacity, cost efficiency, and environmental conditions.

Cost Comparison: Lightweight Gypsum vs Regular Gypsum

Lightweight gypsum typically costs 10-15% more than regular gypsum due to the added materials and manufacturing processes that reduce density. Regular gypsum remains more economical for large-scale projects where weight is less of a concern, offering a cost-effective solution without compromising basic performance. Choosing between the two depends on budget constraints and specific project requirements, as lightweight gypsum provides savings in labor and transportation despite its higher upfront price.

Environmental Impact and Sustainability Factors

Lightweight gypsum offers enhanced environmental benefits compared to regular gypsum due to its lower material density, which reduces transportation emissions and energy consumption during manufacturing. Its composition often incorporates recycled materials and requires less raw gypsum extraction, contributing to resource conservation and minimizing landfill waste. These sustainability factors highlight lightweight gypsum as a more eco-friendly choice for construction projects aiming to reduce carbon footprint and promote circular economy principles.

Lightweight gypsum vs Regular gypsum Infographic

materialdif.com

materialdif.com