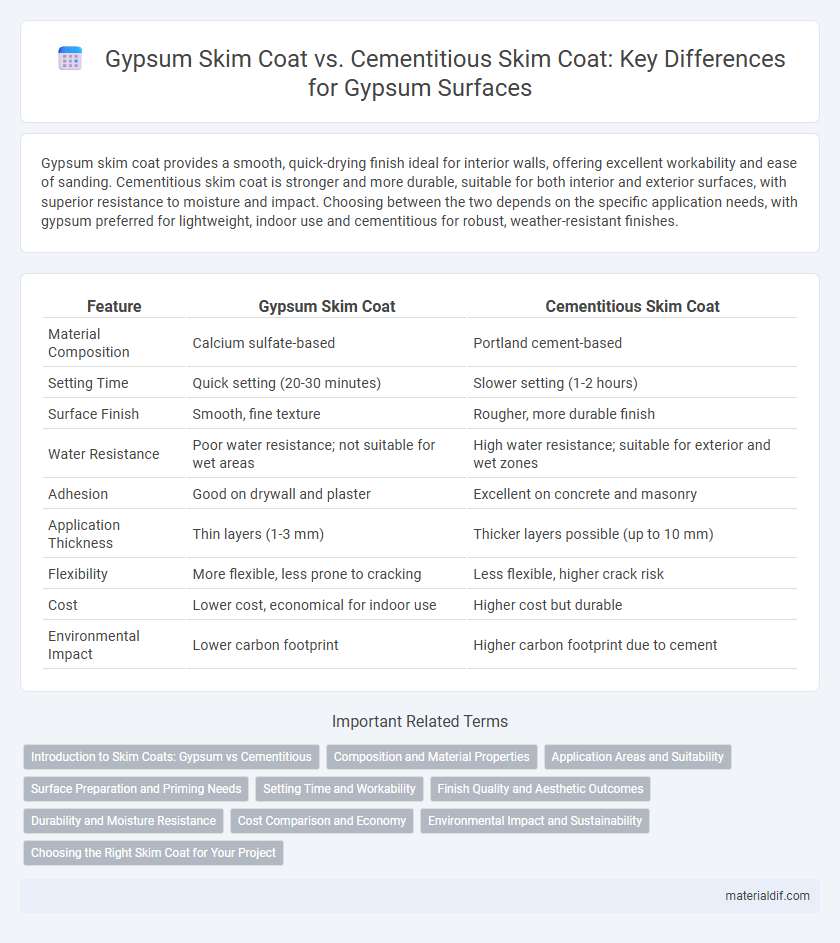

Gypsum skim coat provides a smooth, quick-drying finish ideal for interior walls, offering excellent workability and ease of sanding. Cementitious skim coat is stronger and more durable, suitable for both interior and exterior surfaces, with superior resistance to moisture and impact. Choosing between the two depends on the specific application needs, with gypsum preferred for lightweight, indoor use and cementitious for robust, weather-resistant finishes.

Table of Comparison

| Feature | Gypsum Skim Coat | Cementitious Skim Coat |

|---|---|---|

| Material Composition | Calcium sulfate-based | Portland cement-based |

| Setting Time | Quick setting (20-30 minutes) | Slower setting (1-2 hours) |

| Surface Finish | Smooth, fine texture | Rougher, more durable finish |

| Water Resistance | Poor water resistance; not suitable for wet areas | High water resistance; suitable for exterior and wet zones |

| Adhesion | Good on drywall and plaster | Excellent on concrete and masonry |

| Application Thickness | Thin layers (1-3 mm) | Thicker layers possible (up to 10 mm) |

| Flexibility | More flexible, less prone to cracking | Less flexible, higher crack risk |

| Cost | Lower cost, economical for indoor use | Higher cost but durable |

| Environmental Impact | Lower carbon footprint | Higher carbon footprint due to cement |

Introduction to Skim Coats: Gypsum vs Cementitious

Gypsum skim coats provide a smooth, lightweight finish ideal for interior walls and ceilings, offering quick drying time and ease of application. Cementitious skim coats, composed of cement-based materials, deliver superior durability and moisture resistance, making them suitable for exterior surfaces and high-humidity areas. Both types enhance surface texture and prepare substrates for painting or wallpapering but differ significantly in composition, performance, and application environments.

Composition and Material Properties

Gypsum skim coat consists primarily of calcium sulfate dihydrate, known for its smooth finish, fast setting time, and excellent workability, making it ideal for interior wall applications. Cementitious skim coat is composed of Portland cement, fine aggregates, and additives, offering superior adhesion, durability, and moisture resistance suitable for both interior and exterior surfaces. The calcium sulfate base of gypsum ensures ease of sanding and a fine texture, whereas the cementitious mix provides enhanced strength and water resistance, crucial for high-traffic or humid environments.

Application Areas and Suitability

Gypsum skim coat is ideal for interior walls and ceilings, providing a smooth, lightweight finish that enhances paint adhesion and surface uniformity. Cementitious skim coat is more suitable for exterior surfaces, concrete, and masonry due to its durability and resistance to moisture and weather conditions. Each type is selected based on substrate compatibility and environmental exposure, ensuring optimal performance and longevity.

Surface Preparation and Priming Needs

Gypsum skim coat requires a clean, dry, and dust-free surface, often needing a primer to enhance adhesion and prevent moisture absorption. Cementitious skim coat demands more intensive surface preparation, including removing loose particles and applying a bonding agent or primer to ensure proper bonding on concrete or masonry substrates. Proper priming for both types is essential to achieve a smooth finish and long-lasting durability.

Setting Time and Workability

Gypsum skim coat offers a faster setting time, typically hardening within 30 to 60 minutes, making it ideal for quick project turnarounds. Its smooth texture provides excellent workability, allowing easy application and fine finishing on interior surfaces. In contrast, cementitious skim coats have a longer setting time, often requiring several hours to fully cure, but they provide superior durability and moisture resistance for exterior or high-humidity areas.

Finish Quality and Aesthetic Outcomes

Gypsum skim coat provides a smoother, finer finish ideal for interior walls, enhancing paint adhesion and delivering a high-quality, aesthetically pleasing surface. Cementitious skim coat offers superior durability and moisture resistance, making it suitable for exterior applications but may result in a rougher texture. The choice between gypsum and cementitious skim coats significantly impacts the finish quality and visual appeal, with gypsum preferred for delicate, polished interiors and cementitious favored for robust, weather-resistant finishes.

Durability and Moisture Resistance

Gypsum skim coat offers smooth finishing with limited durability and moderate moisture resistance, making it suitable for interior, dry environments. Cementitious skim coat provides superior durability and high moisture resistance due to its cement-based composition, ideal for exterior walls and wet areas. The cementitious option is preferred where structural strength and long-term water exposure protection are critical.

Cost Comparison and Economy

Gypsum skim coats generally offer a more cost-effective solution compared to cementitious skim coats due to lower material prices and faster application times, reducing overall labor expenses. Cementitious skim coats, while more expensive upfront, provide superior durability and water resistance, which can lead to long-term savings in high-moisture environments or heavy-use areas. For budget-conscious projects prioritizing quick finishes and smooth surfaces, gypsum skim coats are economically advantageous, whereas cementitious options justify their higher cost through enhanced performance and longevity.

Environmental Impact and Sustainability

Gypsum skim coats offer a lower environmental impact compared to cementitious skim coats due to their natural mineral composition and lower energy consumption during production. Cementitious skim coats typically have higher embodied carbon emissions because of cement manufacturing, which involves significant CO2 release. Choosing gypsum enhances sustainability by promoting recyclability and reducing landfill waste in construction projects.

Choosing the Right Skim Coat for Your Project

Gypsum skim coat offers a smooth, easy-to-apply finish ideal for interior walls and ceilings, providing excellent fire resistance and moisture regulation. Cementitious skim coat, made from cement-based materials, is better suited for exterior surfaces and high-moisture areas due to its superior durability and water resistance. Choosing the right skim coat depends on the project's requirements, with gypsum favored for aesthetic interiors and cementitious preferred for strength and longevity in harsh conditions.

Gypsum skim coat vs Cementitious skim coat Infographic

materialdif.com

materialdif.com