Calcined gypsum is produced by heating raw gypsum to remove water content, resulting in a dry powder that sets quickly when mixed with water. Raw gypsum contains natural moisture and impurities, making it less reactive and slower to set in construction applications. The enhanced workability and faster drying time of calcined gypsum make it ideal for plastering, wallboard production, and quick repair work.

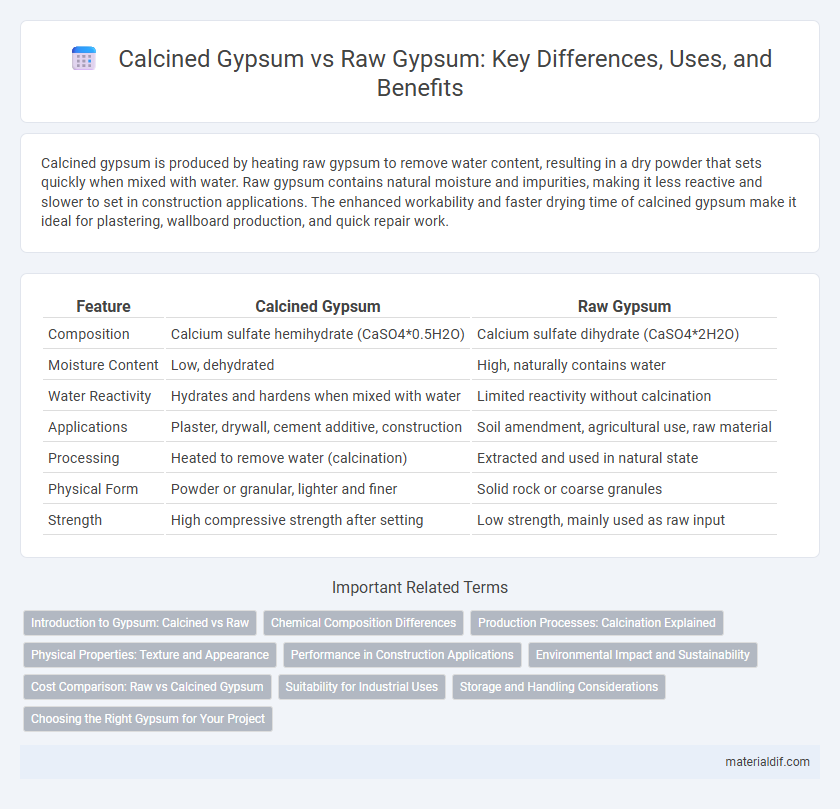

Table of Comparison

| Feature | Calcined Gypsum | Raw Gypsum |

|---|---|---|

| Composition | Calcium sulfate hemihydrate (CaSO4*0.5H2O) | Calcium sulfate dihydrate (CaSO4*2H2O) |

| Moisture Content | Low, dehydrated | High, naturally contains water |

| Water Reactivity | Hydrates and hardens when mixed with water | Limited reactivity without calcination |

| Applications | Plaster, drywall, cement additive, construction | Soil amendment, agricultural use, raw material |

| Processing | Heated to remove water (calcination) | Extracted and used in natural state |

| Physical Form | Powder or granular, lighter and finer | Solid rock or coarse granules |

| Strength | High compressive strength after setting | Low strength, mainly used as raw input |

Introduction to Gypsum: Calcined vs Raw

Calcined gypsum is produced by heating raw gypsum to remove water content, resulting in a fine powder used in construction and agriculture for faster setting and improved strength. Raw gypsum, a naturally occurring mineral composed of calcium sulfate dihydrate, is primarily used in its natural form for soil conditioning and as a raw material for calcination. The calcination process transforms raw gypsum into a more reactive form, enhancing its performance in applications like plaster, drywall, and cement additives.

Chemical Composition Differences

Calcined gypsum undergoes thermal treatment to remove water molecules, resulting in calcium sulfate hemihydrate (CaSO4*0.5H2O), while raw gypsum primarily consists of calcium sulfate dihydrate (CaSO4*2H2O). This chemical transformation reduces the water content and alters the crystalline structure, enhancing calcined gypsum's solubility and reactivity compared to raw gypsum. The distinct hydration states critically influence their applications in construction, with calcined gypsum favored for plaster and molding due to its quick setting properties.

Production Processes: Calcination Explained

Calcined gypsum is produced by heating raw gypsum to remove water content, a process known as calcination, which transforms calcium sulfate dihydrate into calcium sulfate hemihydrate. This thermal treatment enhances gypsum's properties, making it more suitable for construction applications such as plaster and drywall. Raw gypsum, composed mainly of calcium sulfate dihydrate, requires this calcination step to improve workability, setting time, and strength of the final product.

Physical Properties: Texture and Appearance

Calcined gypsum undergoes a heating process that removes moisture, resulting in a fine, powdery texture distinct from the coarse, crystalline structure of raw gypsum. The appearance of calcined gypsum is typically lighter and more uniform, while raw gypsum exhibits a denser, granular form with visible crystal formations. These physical differences significantly impact their applications in construction and manufacturing, where texture and consistency are critical.

Performance in Construction Applications

Calcined gypsum exhibits superior performance in construction due to its enhanced setting time and improved strength compared to raw gypsum. The calcination process removes excess water, resulting in a more stable and durable material ideal for plastering and drywall applications. Raw gypsum, while abundant and natural, lacks the mechanical properties necessary for high-performance construction uses.

Environmental Impact and Sustainability

Calcined gypsum, produced by heating raw gypsum to remove water content, significantly reduces waste by enabling the reuse of byproducts in construction and agriculture, thus minimizing landfill impact. Raw gypsum mining disrupts ecosystems and generates higher carbon emissions due to extensive extraction processes, whereas calcined gypsum's energy-efficient production lowers greenhouse gas emissions. Utilizing calcined gypsum promotes circular economy practices and enhances sustainability by decreasing resource depletion and supporting low-carbon building materials.

Cost Comparison: Raw vs Calcined Gypsum

Calcined gypsum undergoes a thermal process that increases production costs compared to raw gypsum, which is simply mined and requires minimal processing. Despite higher initial costs, calcined gypsum offers enhanced properties like improved setting time and strength, potentially reducing overall project expenses. Raw gypsum remains more cost-effective for applications with lower performance demands, making it a budget-friendly choice in large-scale construction where material quality is less critical.

Suitability for Industrial Uses

Calcined gypsum, produced by heating raw gypsum to remove moisture, offers enhanced suitability for industrial uses due to its improved hardness, reduced setting time, and better workability compared to raw gypsum. Its controlled physical and chemical properties make it ideal for applications in plasterboard manufacturing, cement additives, and agriculture. Raw gypsum, while abundant and cost-effective, lacks the consistent performance characteristics required for specialized industrial processes.

Storage and Handling Considerations

Calcined gypsum requires dry, airtight storage to prevent moisture absorption, which can cause caking and reduce its effectiveness, whereas raw gypsum is more stable but still susceptible to humidity. Handling calcined gypsum demands specialized equipment to minimize dust generation and maintain material integrity, contrasting with raw gypsum, which is easier to handle but bulkier. Both forms benefit from cool, dry storage environments to preserve quality and facilitate efficient transportation.

Choosing the Right Gypsum for Your Project

Calcined gypsum undergoes controlled heating to remove water content, resulting in a material that sets faster and offers superior strength compared to raw gypsum, which is naturally occurring and contains more moisture. For projects requiring quick setting times and higher durability, calcined gypsum is the optimal choice, especially in construction applications like plastering and drywall installation. Raw gypsum suits agricultural uses or situations where slower setting times are acceptable, providing essential calcium sulfate without the manufacturing alterations.

Calcined Gypsum vs Raw Gypsum Infographic

materialdif.com

materialdif.com