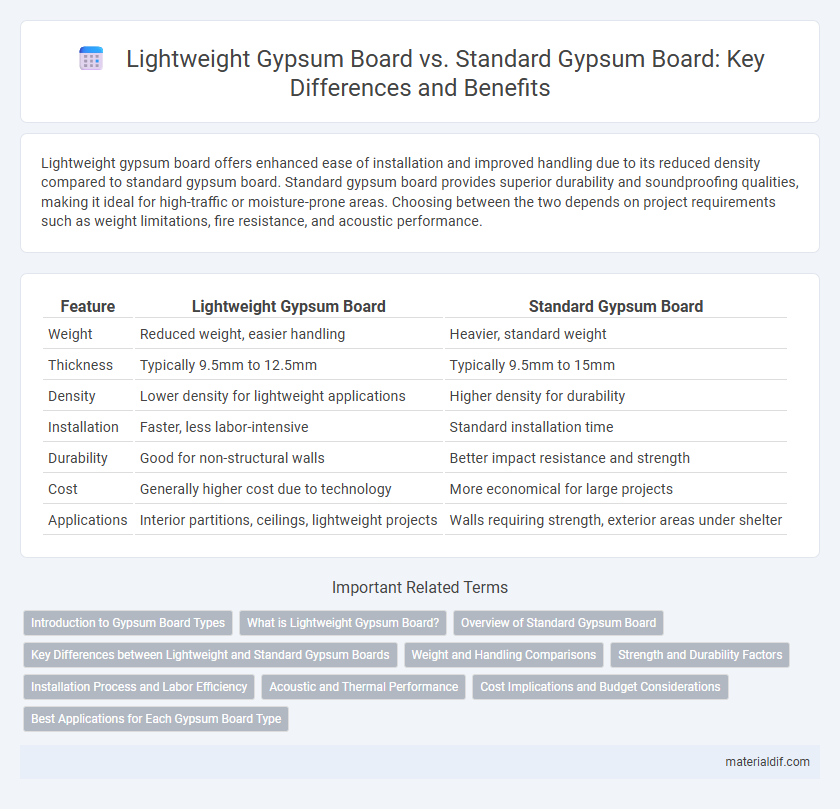

Lightweight gypsum board offers enhanced ease of installation and improved handling due to its reduced density compared to standard gypsum board. Standard gypsum board provides superior durability and soundproofing qualities, making it ideal for high-traffic or moisture-prone areas. Choosing between the two depends on project requirements such as weight limitations, fire resistance, and acoustic performance.

Table of Comparison

| Feature | Lightweight Gypsum Board | Standard Gypsum Board |

|---|---|---|

| Weight | Reduced weight, easier handling | Heavier, standard weight |

| Thickness | Typically 9.5mm to 12.5mm | Typically 9.5mm to 15mm |

| Density | Lower density for lightweight applications | Higher density for durability |

| Installation | Faster, less labor-intensive | Standard installation time |

| Durability | Good for non-structural walls | Better impact resistance and strength |

| Cost | Generally higher cost due to technology | More economical for large projects |

| Applications | Interior partitions, ceilings, lightweight projects | Walls requiring strength, exterior areas under shelter |

Introduction to Gypsum Board Types

Lightweight gypsum board is engineered with a core containing additional air pockets or lightweight fillers to reduce overall density, enhancing ease of handling and installation while maintaining fire resistance and sound insulation. Standard gypsum board features a denser, more compact gypsum core offering superior durability and impact resistance, commonly used in walls and ceilings where strength is prioritized. Both types utilize a calcium sulfate dihydrate core encased in paper facings, but the choice depends on specific requirements for weight, structural performance, and application environment.

What is Lightweight Gypsum Board?

Lightweight gypsum board is a specialized construction material engineered to be lighter than standard gypsum board through the incorporation of air-filled microspheres or foam agents, reducing the overall weight while maintaining strength and fire resistance. It offers easier handling and faster installation, making it ideal for large-scale projects and applications where weight reduction is critical, such as ceiling systems and high-rise buildings. Compared to standard gypsum board, lightweight variants provide improved acoustic properties and enhanced thermal insulation performance, contributing to energy-efficient building designs.

Overview of Standard Gypsum Board

Standard gypsum board, commonly known as drywall, consists of a dense core of gypsum plaster sandwiched between two thick layers of paper, offering robust fire resistance and durability. It typically measures 1/2 inch in thickness and weighs about 2.3 to 2.9 pounds per square foot, providing solid soundproofing and structural strength for interior walls and ceilings. Standard gypsum board is widely used in residential and commercial construction due to its affordability, ease of installation, and compatibility with various finishes.

Key Differences between Lightweight and Standard Gypsum Boards

Lightweight gypsum board offers reduced density, typically around 8-10 lbs per 4x8 foot sheet, compared to standard gypsum board which weighs approximately 10-15 lbs for the same size, making it easier to handle and install. The core composition of lightweight gypsum board incorporates specialized additives to enhance workability while maintaining fire resistance, whereas standard gypsum board has a denser core providing higher impact resistance and durability. Sound insulation properties differ as well; standard gypsum board generally provides better acoustic performance due to its mass, whereas lightweight versions may require additional layering or insulation to achieve comparable soundproofing.

Weight and Handling Comparisons

Lightweight gypsum board typically weighs 20-30% less than standard gypsum board, making it easier to transport and install with less physical strain. The reduced weight improves handling efficiency on-site, especially for ceiling applications and tight spaces. Despite the lighter mass, lightweight boards maintain comparable strength and fire resistance properties to standard gypsum boards.

Strength and Durability Factors

Lightweight gypsum board offers reduced weight while maintaining adequate strength for most interior applications, making installation easier without compromising structural integrity. Standard gypsum board is generally denser and provides superior durability and impact resistance, ideal for high-traffic or demanding environments. The choice between lightweight and standard gypsum boards depends on balancing ease of handling with the required strength and long-term performance in specific construction projects.

Installation Process and Labor Efficiency

Lightweight gypsum board offers faster installation due to its reduced weight, enabling easier handling and minimizing worker fatigue compared to standard gypsum board. The decreased weight accelerates cutting, fitting, and securing, resulting in shorter project timelines and enhanced labor efficiency. Standard gypsum board, while more rigid, typically requires additional manpower and effort for installation, impacting overall productivity and increasing labor costs.

Acoustic and Thermal Performance

Lightweight gypsum boards offer enhanced acoustic insulation due to their lower density and porous structure, effectively reducing sound transmission in residential and commercial spaces. Standard gypsum boards provide superior thermal performance with higher mass, contributing to better heat retention and energy efficiency in building envelopes. Selecting between lightweight and standard gypsum boards depends on prioritizing soundproofing needs or thermal regulation requirements for optimal indoor comfort.

Cost Implications and Budget Considerations

Lightweight gypsum board typically costs 10-20% more than standard gypsum board due to its enhanced workability and reduced weight, which can lower labor expenses by up to 15% during installation. Standard gypsum board remains a budget-friendly option for large-scale projects, offering a lower initial material cost but potentially higher transportation and handling fees. Budget considerations should weigh the trade-off between upfront material costs versus long-term savings in labor and logistics when selecting between lightweight and standard gypsum boards.

Best Applications for Each Gypsum Board Type

Lightweight gypsum board is ideal for residential walls and ceilings where ease of handling and reduced structural load are priorities, often used in renovations and multi-story buildings. Standard gypsum board provides superior durability and soundproofing, making it suitable for high-traffic commercial spaces and areas requiring enhanced fire resistance. Both types are essential for tailored construction solutions depending on project-specific demands such as weight constraints and acoustic performance.

Lightweight Gypsum Board vs Standard Gypsum Board Infographic

materialdif.com

materialdif.com