Gypsum wallboard offers superior fire resistance and soundproofing compared to plywood wallboard, making it ideal for interior walls in residential and commercial buildings. Unlike plywood, gypsum wallboard is non-combustible and provides better moisture resistance when treated, reducing the risk of mold and mildew. It also allows for easier installation and finishing, resulting in a smooth, paint-ready surface.

Table of Comparison

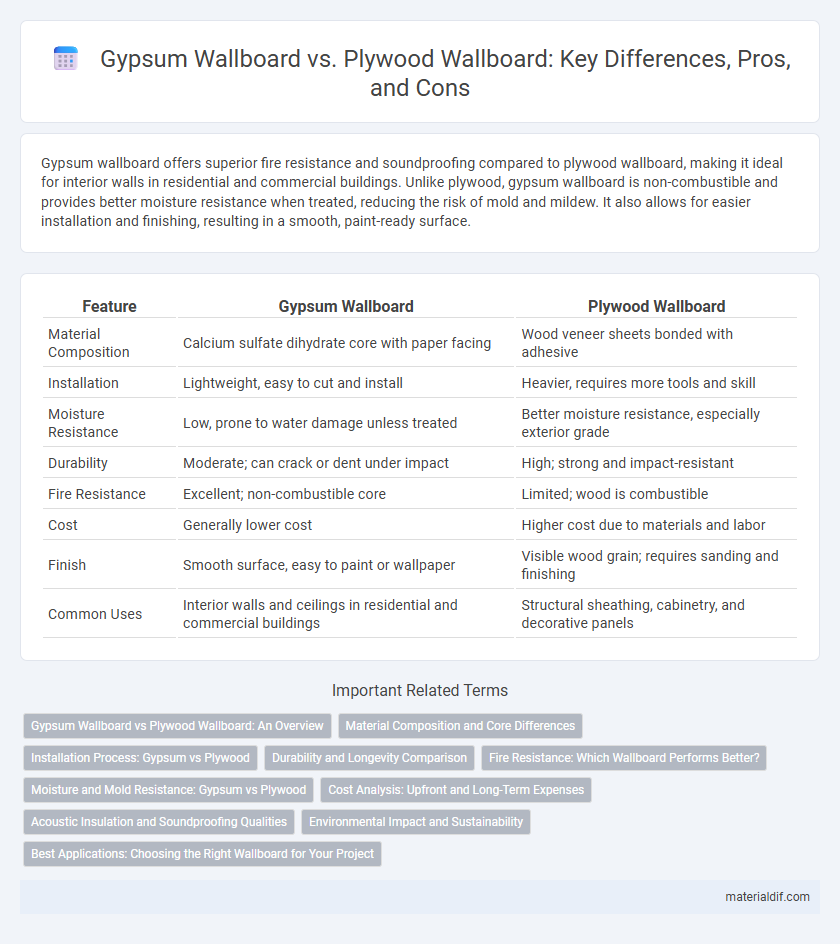

| Feature | Gypsum Wallboard | Plywood Wallboard |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate core with paper facing | Wood veneer sheets bonded with adhesive |

| Installation | Lightweight, easy to cut and install | Heavier, requires more tools and skill |

| Moisture Resistance | Low, prone to water damage unless treated | Better moisture resistance, especially exterior grade |

| Durability | Moderate; can crack or dent under impact | High; strong and impact-resistant |

| Fire Resistance | Excellent; non-combustible core | Limited; wood is combustible |

| Cost | Generally lower cost | Higher cost due to materials and labor |

| Finish | Smooth surface, easy to paint or wallpaper | Visible wood grain; requires sanding and finishing |

| Common Uses | Interior walls and ceilings in residential and commercial buildings | Structural sheathing, cabinetry, and decorative panels |

Gypsum Wallboard vs Plywood Wallboard: An Overview

Gypsum wallboard consists of a core of gypsum plaster pressed between two thick sheets of paper, offering superior fire resistance and soundproofing compared to plywood wallboards, which are made from thin layers of wood veneer glued together. Gypsum wallboard is lightweight, easier to install, and more cost-effective, making it widely preferred for interior walls and ceilings in residential and commercial construction. Plywood wallboards provide higher structural strength and moisture resistance, suitable for applications requiring durability and load-bearing capacity.

Material Composition and Core Differences

Gypsum wallboard consists primarily of a gypsum core encased in paper, providing fire resistance and soundproofing benefits due to its mineral composition. Plywood wallboard is made from thin layers of wood veneer glued together, offering superior structural strength and flexibility but lacking the inherent fire-resistant properties of gypsum. The core difference lies in gypsum's mineral-based, non-combustible core compared to plywood's natural wood composition, which affects durability, moisture resistance, and application suitability.

Installation Process: Gypsum vs Plywood

Gypsum wallboard installation involves securing large, lightweight panels to studs using drywall screws or nails, followed by taping, mudding, and sanding to create a smooth finish ideal for painting or wallpapering. Plywood wallboard installation requires nailing or screwing thicker, heavier sheets directly to framing, often needing pre-drilling and sealing to prevent moisture damage, with less emphasis on surface finishing. Gypsum offers faster, cleaner installation suited for interior walls, while plywood provides greater structural strength but demands more labor-intensive preparation and finishing.

Durability and Longevity Comparison

Gypsum wallboard offers superior fire resistance and moisture control compared to plywood wallboard, making it more durable in environments prone to humidity and heat exposure. Plywood wallboard boasts higher structural strength and impact resistance, contributing to its longevity in load-bearing applications or areas subject to physical wear. While gypsum wallboard requires replacement after water damage, plywood wallboard can often be repaired, enhancing its lifespan in certain conditions.

Fire Resistance: Which Wallboard Performs Better?

Gypsum wallboard exhibits superior fire resistance compared to plywood wallboard due to its non-combustible core containing chemically combined water that releases steam when heated, effectively slowing fire spread. Plywood wallboards, being organic and combustible, ignite and burn more readily, providing less protection during fire events. Building codes often prioritize gypsum in fire-rated assemblies for enhanced safety and compliance.

Moisture and Mold Resistance: Gypsum vs Plywood

Gypsum wallboard offers superior moisture and mold resistance compared to plywood wallboard due to its inorganic, non-porous composition, which inhibits mold growth and prevents water absorption. Plywood wallboard, composed of organic wood fibers, is more susceptible to moisture retention and mold development, especially in high-humidity environments. Choosing gypsum wallboard enhances durability and indoor air quality by reducing the risk of mold-related damage and health issues.

Cost Analysis: Upfront and Long-Term Expenses

Gypsum wallboard typically costs less upfront, with prices averaging $0.30 to $0.40 per square foot, compared to plywood wallboard's $0.75 to $1.25 per square foot. Long-term expenses for gypsum are lower due to its resistance to fire, mold, and moisture, reducing maintenance and replacement costs. Plywood may incur higher long-term costs from susceptibility to warping, rot, and termite damage, increasing repair and treatment expenses over time.

Acoustic Insulation and Soundproofing Qualities

Gypsum wallboard provides superior acoustic insulation due to its dense, non-porous surface that effectively absorbs and reduces airborne sound transmission, making it ideal for quieter indoor environments. Plywood wallboard, while structurally strong, has less soundproofing capability as its composition allows more vibration and sound passage through its fibers. For enhanced soundproofing, gypsum wallboard is often preferred in settings requiring noise reduction, such as residential and commercial interiors.

Environmental Impact and Sustainability

Gypsum wallboard produces less environmental pollution during manufacturing and is highly recyclable, reducing landfill waste compared to plywood wallboard, which requires harvesting timber and contributes to deforestation. The production of gypsum wallboard consumes less energy and emits fewer greenhouse gases, supporting lower carbon footprints in construction projects. Plywood wallboard, while renewable if sourced from sustainably managed forests, generally has higher embodied energy and longer decomposition periods in landfills.

Best Applications: Choosing the Right Wallboard for Your Project

Gypsum wallboard excels in fire resistance and soundproofing, making it ideal for interior walls and ceilings in residential and commercial buildings. Plywood wallboard offers superior structural strength and moisture resistance, suitable for areas requiring durability such as exterior sheathing and high-humidity environments. Selecting gypsum or plywood wallboard depends on project needs for fire safety, acoustic performance, and environmental exposure.

Gypsum wallboard vs Plywood wallboard Infographic

materialdif.com

materialdif.com