Calcium sulfate dihydrate, commonly known as gypsum, contains two water molecules and is primarily used in its natural form for wall construction and sculpting due to its slow setting properties. Calcium sulfate hemihydrate, or plaster of Paris, results from heating the dihydrate, removing water molecules and making it highly reactive and quick-setting, ideal for casting and mold-making. Understanding the hydration states of calcium sulfate is crucial for selecting the right material based on drying time and application requirements.

Table of Comparison

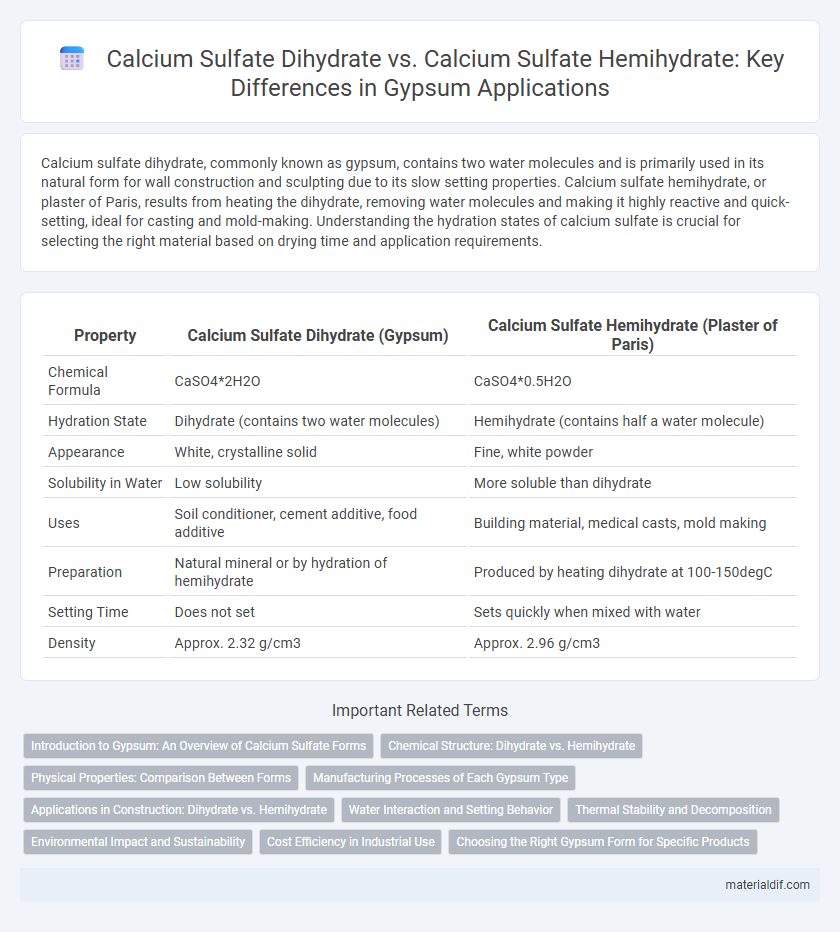

| Property | Calcium Sulfate Dihydrate (Gypsum) | Calcium Sulfate Hemihydrate (Plaster of Paris) |

|---|---|---|

| Chemical Formula | CaSO4*2H2O | CaSO4*0.5H2O |

| Hydration State | Dihydrate (contains two water molecules) | Hemihydrate (contains half a water molecule) |

| Appearance | White, crystalline solid | Fine, white powder |

| Solubility in Water | Low solubility | More soluble than dihydrate |

| Uses | Soil conditioner, cement additive, food additive | Building material, medical casts, mold making |

| Preparation | Natural mineral or by hydration of hemihydrate | Produced by heating dihydrate at 100-150degC |

| Setting Time | Does not set | Sets quickly when mixed with water |

| Density | Approx. 2.32 g/cm3 | Approx. 2.96 g/cm3 |

Introduction to Gypsum: An Overview of Calcium Sulfate Forms

Calcium sulfate dihydrate (CaSO4*2H2O) and calcium sulfate hemihydrate (CaSO4*0.5H2O) are two primary forms of gypsum with distinct chemical compositions and properties. The dihydrate form, commonly known as natural gypsum, contains two molecules of water and is widely used in agriculture and construction for its moisture-retaining capabilities. In contrast, the hemihydrate form, produced by heating the dihydrate, is essential in manufacturing plaster, drywall, and cement due to its rapid setting and hardening characteristics.

Chemical Structure: Dihydrate vs. Hemihydrate

Calcium sulfate dihydrate (CaSO4*2H2O) contains two water molecules chemically bonded per formula unit, forming a stable crystalline structure commonly known as gypsum. In contrast, calcium sulfate hemihydrate (CaSO4*0.5H2O) has only half a water molecule per formula unit, resulting from the partial dehydration of gypsum and leading to a porous, less stable crystal lattice. The variation in water content directly influences the physical properties and rehydration behavior of these compounds in construction and industrial applications.

Physical Properties: Comparison Between Forms

Calcium sulfate dihydrate, known as gypsum, contains two water molecules per formula unit, resulting in a crystalline structure that is soft and has low hardness, with a Mohs hardness of around 2. In contrast, calcium sulfate hemihydrate, commonly referred to as plaster of Paris, has half a water molecule per formula unit, exhibiting a finer, powdery texture that becomes hard and dense upon rehydration and setting. The dihydrate form is stable at room temperature and less porous, whereas the hemihydrate form is more reactive and porous, influencing their respective applications in construction and medical casting.

Manufacturing Processes of Each Gypsum Type

Calcium sulfate dihydrate is primarily obtained through natural mining or synthetic crystallization, involving the hydration of calcium sulfate to form its stable dihydrate structure. In contrast, calcium sulfate hemihydrate is produced by calcining gypsum at high temperatures, driving off part of the water content and resulting in a fine, powdery material used in plaster and construction. The controlled heating process and temperature adjustments differentiate the manufacturing outcomes between the stable dihydrate and reactive hemihydrate forms.

Applications in Construction: Dihydrate vs. Hemihydrate

Calcium sulfate dihydrate, commonly known as natural gypsum, is primarily used in construction for drywall and plaster due to its stable crystalline structure and slow-setting properties, providing excellent fire resistance and sound insulation. Calcium sulfate hemihydrate, or plaster of Paris, is favored for rapid-setting applications such as moldings, repairs, and casts because it hardens quickly upon mixing with water. The hemihydrate's faster hydration rate and higher strength make it suitable for detailed architectural features, while the dihydrate's durability supports large-scale structural use.

Water Interaction and Setting Behavior

Calcium sulfate dihydrate (CaSO4*2H2O) contains two water molecules, resulting in low water interaction and minimal expansion during setting. In contrast, calcium sulfate hemihydrate (CaSO4*0.5H2O) absorbs water rapidly, forming a supersaturated solution that initiates crystallization and hardening through rehydration to the dihydrate form. The setting behavior of hemihydrate is characterized by exothermic crystallization and volume stability, whereas dihydrate remains largely inert in aqueous environments.

Thermal Stability and Decomposition

Calcium sulfate dihydrate (CaSO4*2H2O) exhibits thermal stability up to approximately 150degC, where it begins to lose water molecules and undergoes endothermic decomposition to form calcium sulfate hemihydrate (CaSO4*0.5H2O). Calcium sulfate hemihydrate demonstrates increased thermal resistance, remaining stable until around 170-180degC before further dehydration leads to anhydrous calcium sulfate. The decomposition process of dihydrate to hemihydrate involves partial water loss, while hemihydrate transitions to anhydrite through complete dehydration at higher temperatures.

Environmental Impact and Sustainability

Calcium sulfate dihydrate, commonly known as gypsum, exhibits a lower environmental impact due to its natural occurrence and minimal processing requirements compared to calcium sulfate hemihydrate, which undergoes energy-intensive dehydration. The production of calcium sulfate hemihydrate generates higher CO2 emissions and consumes more energy, impacting sustainability negatively. Utilizing calcium sulfate dihydrate in construction and agriculture promotes waste reduction and resource efficiency, making it a more sustainable choice in industrial applications.

Cost Efficiency in Industrial Use

Calcium sulfate dihydrate, commonly known as gypsum, offers cost efficiency in industrial use due to its abundance and lower processing requirements compared to calcium sulfate hemihydrate. Calcium sulfate hemihydrate, or plaster of Paris, involves additional calcination steps that increase production costs but provide faster setting times and higher strength for specialized applications. Industrial sectors prioritize calcium sulfate dihydrate for bulk uses like cement and soil conditioning when minimizing expenses is critical, while hemihydrate is reserved for value-added products where performance justifies higher costs.

Choosing the Right Gypsum Form for Specific Products

Calcium sulfate dihydrate offers superior setting control and is ideal for applications requiring slow drying and high strength, such as wall plasters and dental molds. Calcium sulfate hemihydrate, characterized by its rapid setting time and ease of mixing with water, is preferred for quick-setting products like drywall and casting materials. Selecting the appropriate gypsum form depends on the required setting time, strength, and application method to ensure optimal product performance.

Calcium sulfate dihydrate vs Calcium sulfate hemihydrate Infographic

materialdif.com

materialdif.com