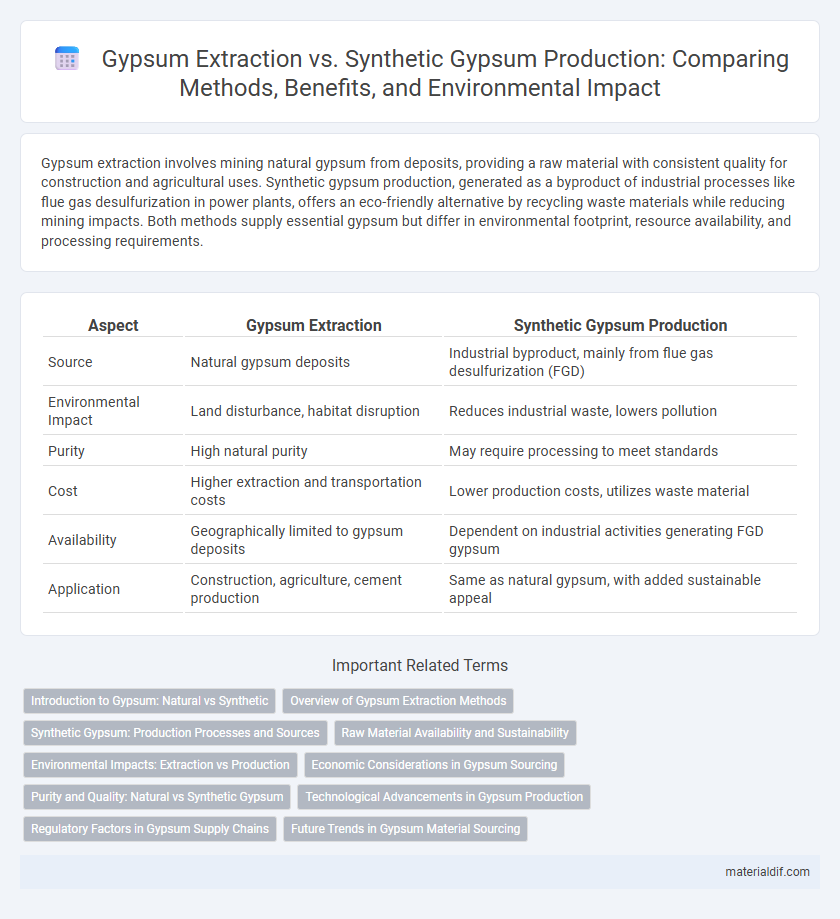

Gypsum extraction involves mining natural gypsum from deposits, providing a raw material with consistent quality for construction and agricultural uses. Synthetic gypsum production, generated as a byproduct of industrial processes like flue gas desulfurization in power plants, offers an eco-friendly alternative by recycling waste materials while reducing mining impacts. Both methods supply essential gypsum but differ in environmental footprint, resource availability, and processing requirements.

Table of Comparison

| Aspect | Gypsum Extraction | Synthetic Gypsum Production |

|---|---|---|

| Source | Natural gypsum deposits | Industrial byproduct, mainly from flue gas desulfurization (FGD) |

| Environmental Impact | Land disturbance, habitat disruption | Reduces industrial waste, lowers pollution |

| Purity | High natural purity | May require processing to meet standards |

| Cost | Higher extraction and transportation costs | Lower production costs, utilizes waste material |

| Availability | Geographically limited to gypsum deposits | Dependent on industrial activities generating FGD gypsum |

| Application | Construction, agriculture, cement production | Same as natural gypsum, with added sustainable appeal |

Introduction to Gypsum: Natural vs Synthetic

Gypsum is a soft sulfate mineral commonly extracted from natural deposits used in construction, agriculture, and industrial applications. Natural gypsum forms through sedimentary processes involving the evaporation of seawater, while synthetic gypsum is a byproduct of industrial activities such as flue gas desulfurization in power plants. Synthetic gypsum offers a sustainable alternative by recycling waste material, reducing environmental impact compared to traditional mining methods.

Overview of Gypsum Extraction Methods

Gypsum extraction primarily involves open-pit mining, where large deposits of natural gypsum are removed from sedimentary rock formations using heavy machinery. Underground mining techniques are less common but utilized when gypsum deposits lie deep beneath the surface, employing room-and-pillar or cut-and-fill methods to safely access the mineral. Both natural and synthetic gypsum serve critical roles in construction and agriculture, though extraction methods for natural gypsum emphasize minimizing environmental impact and maximizing resource recovery.

Synthetic Gypsum: Production Processes and Sources

Synthetic gypsum is primarily produced through flue gas desulfurization (FGD) in coal-fired power plants, where sulfur dioxide emissions react with limestone to form calcium sulfate dihydrate. This environmentally friendly process not only reduces air pollution but also creates a high-purity gypsum byproduct used in construction materials like drywall and cement. Other sources of synthetic gypsum include phosphogypsum from phosphate fertilizer manufacturing and chemical gypsum generated from various industrial processes.

Raw Material Availability and Sustainability

Natural gypsum extraction relies on mining large deposits of calcium sulfate dihydrate, which can be environmentally disruptive and limited by regional geography. Synthetic gypsum production, generated as a byproduct of industrial processes such as flue gas desulfurization, offers a more sustainable raw material source by recycling waste products and reducing the depletion of natural reserves. The increasing availability of synthetic gypsum supports sustainability goals by minimizing mining impacts and promoting circular economy practices in construction materials.

Environmental Impacts: Extraction vs Production

Gypsum extraction involves quarrying that disrupts landscapes, causes habitat loss, and generates dust and noise pollution, impacting local ecosystems. Synthetic gypsum production, derived from industrial byproducts like flue gas desulfurization, reduces waste and lowers the need for natural resource depletion, but may introduce chemical contaminants if not managed properly. Both methods have carbon footprints, yet synthetic gypsum typically offers a more sustainable alternative by recycling industrial emissions and minimizing quarrying-related environmental degradation.

Economic Considerations in Gypsum Sourcing

Gypsum extraction from natural deposits involves significant operational costs, including mining, transportation, and environmental management, which can fluctuate based on geographic location and deposit quality. Synthetic gypsum production, often sourced from flue gas desulfurization (FGD) in power plants, offers a cost-effective alternative with reduced environmental impact and consistent purity levels. Economic considerations favor synthetic gypsum when balancing extraction expenses, regulatory compliance, and the demand for sustainable building materials.

Purity and Quality: Natural vs Synthetic Gypsum

Natural gypsum extraction yields high-purity calcium sulfate dihydrate containing fewer impurities, ensuring excellent physical properties for construction applications. Synthetic gypsum, produced from flue gas desulfurization, often exhibits consistently controlled composition but may contain trace contaminants such as heavy metals or unreacted chemicals. Both sources provide quality gypsum, though natural gypsum is preferred for applications demanding premium purity, while synthetic gypsum offers sustainable alternatives with comparable performance.

Technological Advancements in Gypsum Production

Technological advancements in gypsum production have significantly improved both natural gypsum extraction and synthetic gypsum manufacturing processes. Innovations such as automated mining equipment and advanced purification techniques enhance extraction efficiency and product quality in natural gypsum, while developments in flue gas desulfurization (FGD) systems enable synthetic gypsum production with lower environmental impact and consistent material properties. These technologies optimize resource utilization, reduce waste, and support sustainable gypsum supply chains for construction and industrial applications.

Regulatory Factors in Gypsum Supply Chains

Gypsum extraction is subject to strict environmental regulations that control land disturbance, water usage, and emissions to minimize ecological impact, leading to longer permitting processes and higher compliance costs. Synthetic gypsum production, often sourced from flue gas desulfurization in power plants, benefits from regulatory incentives promoting waste recycling and emission reductions, enhancing its appeal in sustainable supply chains. Regulatory frameworks increasingly favor synthetic gypsum by imposing stringent limits on mining activities, encouraging industries to adopt eco-friendly production methods to secure long-term gypsum supply.

Future Trends in Gypsum Material Sourcing

Gypsum extraction from natural deposits remains a key source, but synthetic gypsum production from flue gas desulfurization is rapidly gaining traction due to environmental benefits and waste reduction. Future trends indicate an increasing reliance on synthetic gypsum as industries aim to lower carbon footprints and promote sustainable construction materials. Advancements in purification technologies and regulatory support will likely enhance synthetic gypsum's market share, shaping a more eco-friendly gypsum material sourcing landscape.

Gypsum Extraction vs Synthetic Gypsum Production Infographic

materialdif.com

materialdif.com