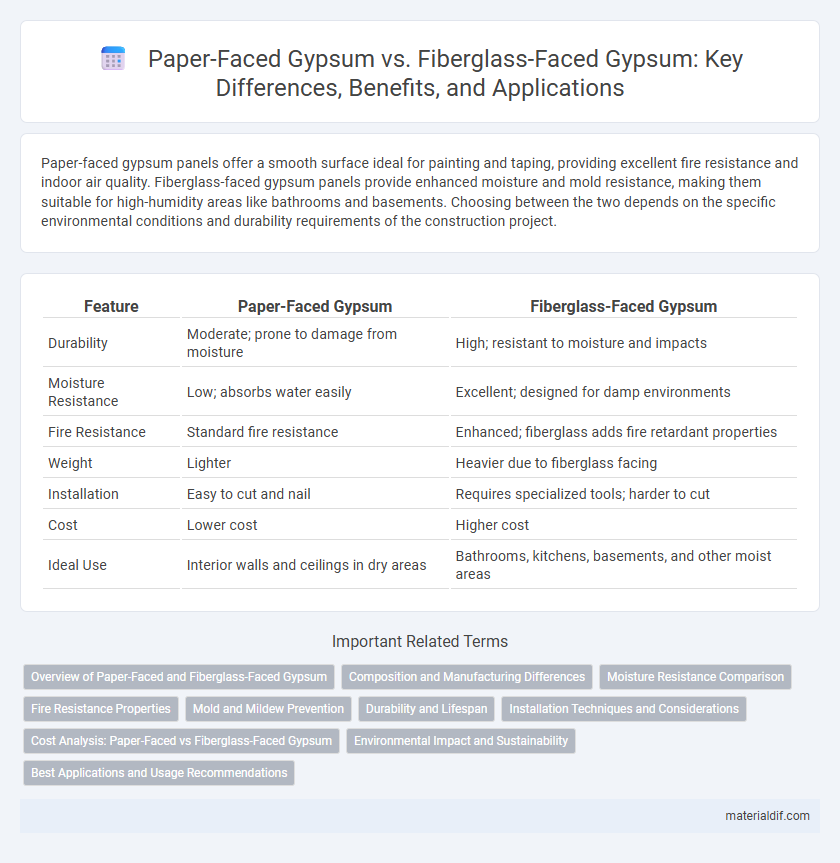

Paper-faced gypsum panels offer a smooth surface ideal for painting and taping, providing excellent fire resistance and indoor air quality. Fiberglass-faced gypsum panels provide enhanced moisture and mold resistance, making them suitable for high-humidity areas like bathrooms and basements. Choosing between the two depends on the specific environmental conditions and durability requirements of the construction project.

Table of Comparison

| Feature | Paper-Faced Gypsum | Fiberglass-Faced Gypsum |

|---|---|---|

| Durability | Moderate; prone to damage from moisture | High; resistant to moisture and impacts |

| Moisture Resistance | Low; absorbs water easily | Excellent; designed for damp environments |

| Fire Resistance | Standard fire resistance | Enhanced; fiberglass adds fire retardant properties |

| Weight | Lighter | Heavier due to fiberglass facing |

| Installation | Easy to cut and nail | Requires specialized tools; harder to cut |

| Cost | Lower cost | Higher cost |

| Ideal Use | Interior walls and ceilings in dry areas | Bathrooms, kitchens, basements, and other moist areas |

Overview of Paper-Faced and Fiberglass-Faced Gypsum

Paper-faced gypsum boards offer smooth surfaces ideal for painting and interior finishing, featuring a cellulose paper facing that enhances adhesion but is susceptible to moisture damage. Fiberglass-faced gypsum boards incorporate a durable fiberglass mat facing that provides superior moisture resistance and mold prevention, making them suitable for high-humidity environments. Both types maintain the core fire-resistant and soundproofing properties of gypsum but differ significantly in durability and application based on their facing materials.

Composition and Manufacturing Differences

Paper-faced gypsum boards consist of a gypsum core encased in cellulose-based paper liners, which provide a smooth surface for finishing and ease of painting. Fiberglass-faced gypsum boards feature a gypsum core coated with a non-combustible fiberglass mat, enhancing moisture resistance and durability in high-humidity or exterior applications. The manufacturing process of paper-faced boards involves layering wet gypsum slurry onto paper sheets, while fiberglass-faced panels use fiberglass mats adhered to the gypsum core through heat and pressure, resulting in distinct performance characteristics.

Moisture Resistance Comparison

Paper-faced gypsum typically offers lower moisture resistance compared to fiberglass-faced gypsum, which is engineered with a water-resistant fiberglass mat that prevents mold and mildew growth in damp environments. Fiberglass-faced gypsum boards are preferred for high-humidity areas such as bathrooms and basements due to their superior durability and resistance to moisture infiltration. The enhanced moisture resistance of fiberglass-faced gypsum significantly extends the lifespan and maintains the structural integrity of walls exposed to wet conditions.

Fire Resistance Properties

Paper-faced gypsum boards provide moderate fire resistance due to the cellulose fibers in the paper, which can burn under intense heat, potentially compromising the board's integrity. Fiberglass-faced gypsum boards offer enhanced fire resistance because the fiberglass facing resists ignition and does not contribute fuel to flames, improving overall safety in fire-prone environments. The non-combustible nature of fiberglass facings combined with the gypsum core results in superior fire performance compared to paper-faced alternatives.

Mold and Mildew Prevention

Paper-faced gypsum boards are more susceptible to mold and mildew growth due to their organic paper surface, which retains moisture and provides a food source for fungi. Fiberglass-faced gypsum boards feature a non-organic fiberglass mat that resists moisture absorption, significantly reducing the risk of mold and mildew development in high-humidity environments. Utilizing fiberglass-faced gypsum in areas prone to moisture enhances durability and indoor air quality by preventing fungal contamination.

Durability and Lifespan

Paper-faced gypsum offers moderate durability suitable for interior applications but is more susceptible to moisture damage and mold growth over time. Fiberglass-faced gypsum provides superior durability with enhanced resistance to moisture, mold, and impact, resulting in an extended lifespan in challenging environments. The fiberglass facing significantly improves structural integrity, making it ideal for high-humidity areas and long-term use.

Installation Techniques and Considerations

Paper-faced gypsum boards are commonly installed using standard drywall techniques such as taping, sanding, and painting, with careful handling to prevent paper surface damage and facilitate joint finishing; they offer excellent paint adhesion and are suitable for interior walls and ceilings. Fiberglass-faced gypsum boards require specialized fastening methods due to their heavier weight and are typically more resistant to moisture and mold, making them ideal for high-humidity environments; cutting can be more challenging, often necessitating carbide-tipped tools for clean edges. Installation considerations for fiberglass-faced gypsum emphasize moisture control and the need for compatible finishing products, whereas paper-faced gypsum demands attention to preventing surface tears and achieving smooth finishes with joint compounds.

Cost Analysis: Paper-Faced vs Fiberglass-Faced Gypsum

Paper-faced gypsum typically costs less upfront than fiberglass-faced gypsum, making it a budget-friendly option for standard drywall applications. Fiberglass-faced gypsum, although more expensive initially, offers enhanced moisture and mold resistance, which can reduce long-term maintenance and replacement costs. Evaluating overall project expenses requires considering initial material prices alongside durability and environmental factors associated with each gypsum type.

Environmental Impact and Sustainability

Paper-faced gypsum boards are often considered more environmentally friendly due to their recyclability and biodegradability, integrating cellulose fibers that reduce landfill waste. Fiberglass-faced gypsum offers improved moisture resistance and durability but involves glass fiber production, which has a higher energy footprint and less straightforward recycling options. Sustainable building practices favor paper-faced gypsum in applications prioritizing low environmental impact, while fiberglass-faced versions are selected for conditions requiring enhanced performance despite a larger ecological footprint.

Best Applications and Usage Recommendations

Paper-faced gypsum is ideal for interior walls and ceilings where smooth finishes and easy painting are required, often used in residential and commercial construction due to its excellent paintability and cost-effectiveness. Fiberglass-faced gypsum excels in areas prone to moisture and humidity, such as bathrooms and basements, offering superior mold and mildew resistance along with enhanced durability. For optimal performance, select paper-faced gypsum in dry, low-moisture environments and fiberglass-faced gypsum in moisture-prone settings to ensure longevity and maintain indoor air quality.

Paper-Faced Gypsum vs Fiberglass-Faced Gypsum Infographic

materialdif.com

materialdif.com