Gypsum-based underlayment offers faster drying times and smoother surface finishes compared to cement-based underlayment, making it ideal for interior flooring applications. It provides excellent moisture regulation and reduces the risk of cracking due to its lightweight and flexible composition. Cement-based underlayment is preferred for applications requiring higher strength and water resistance but generally requires longer curing periods.

Table of Comparison

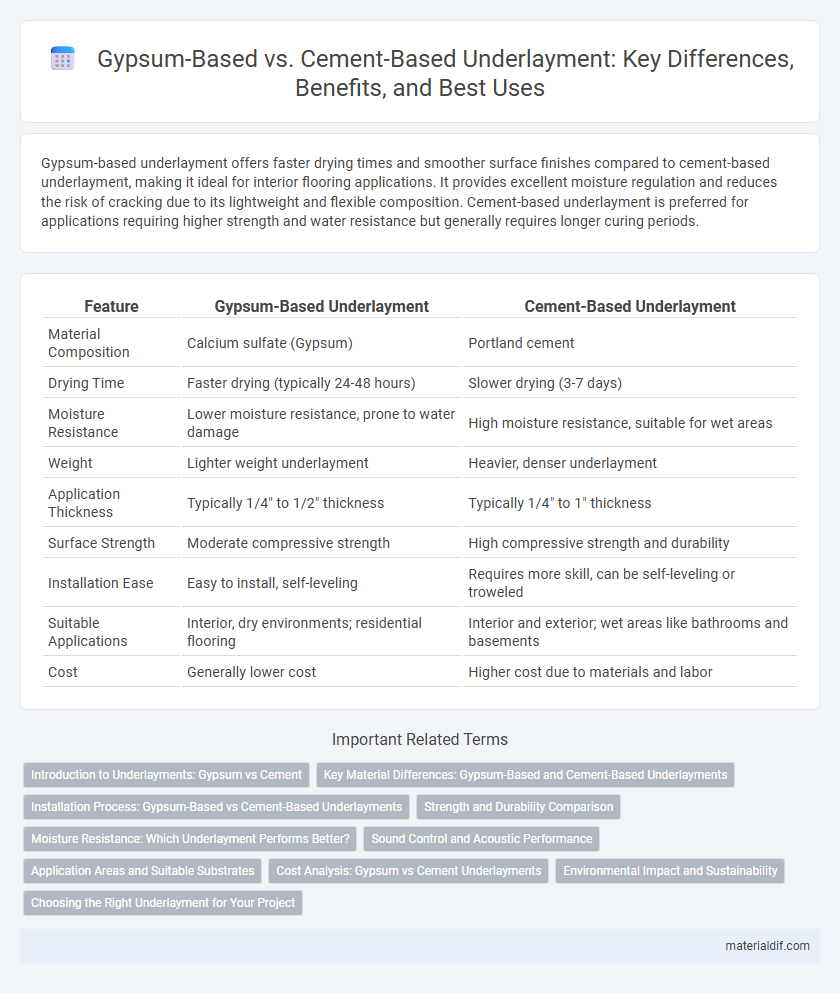

| Feature | Gypsum-Based Underlayment | Cement-Based Underlayment |

|---|---|---|

| Material Composition | Calcium sulfate (Gypsum) | Portland cement |

| Drying Time | Faster drying (typically 24-48 hours) | Slower drying (3-7 days) |

| Moisture Resistance | Lower moisture resistance, prone to water damage | High moisture resistance, suitable for wet areas |

| Weight | Lighter weight underlayment | Heavier, denser underlayment |

| Application Thickness | Typically 1/4" to 1/2" thickness | Typically 1/4" to 1" thickness |

| Surface Strength | Moderate compressive strength | High compressive strength and durability |

| Installation Ease | Easy to install, self-leveling | Requires more skill, can be self-leveling or troweled |

| Suitable Applications | Interior, dry environments; residential flooring | Interior and exterior; wet areas like bathrooms and basements |

| Cost | Generally lower cost | Higher cost due to materials and labor |

Introduction to Underlayments: Gypsum vs Cement

Gypsum-based underlayment offers faster drying times and lighter weight compared to cement-based underlayment, making it ideal for residential flooring projects with tight schedules. Cement-based underlayment provides superior durability and moisture resistance, suitable for high-traffic or wet areas requiring long-term strength. Both materials serve as essential substrates for floor coverings, but gypsum excels in speed and ease of installation while cement ensures robust longevity and moisture protection.

Key Material Differences: Gypsum-Based and Cement-Based Underlayments

Gypsum-based underlayments primarily consist of calcium sulfate, offering faster drying times and smoother finishes compared to cement-based underlayments, which are composed mainly of Portland cement and aggregates. Gypsum underlayments provide excellent moisture resistance in controlled environments but may deteriorate under high moisture conditions, whereas cement-based underlayments exhibit superior durability and moisture tolerance suitable for both interior and exterior applications. The choice between gypsum and cement underlayments significantly impacts installation speed, finishing quality, and long-term performance based on project-specific environmental factors.

Installation Process: Gypsum-Based vs Cement-Based Underlayments

Gypsum-based underlayments offer a faster installation process due to their self-leveling properties and quicker drying times, typically ready for flooring in 24 to 48 hours. Cement-based underlayments require longer curing periods, often taking 7 days or more, and may involve more labor-intensive mixing and application. The ease of use and speed of gypsum-based underlayments make them preferable in time-sensitive projects or where rapid turnaround is critical.

Strength and Durability Comparison

Gypsum-based underlayment offers faster drying times and smoother finishes but generally has lower compressive strength compared to cement-based underlayment, which excels in load-bearing capacity and long-term durability. Cement-based underlayment can withstand higher moisture levels and heavy foot traffic, making it suitable for industrial and exterior applications. Gypsum underlayment is often preferred for interior, dry areas due to its ease of installation and lightweight properties, while cement underlayment provides superior resistance to cracking and wear.

Moisture Resistance: Which Underlayment Performs Better?

Gypsum-based underlayment typically offers lower moisture resistance compared to cement-based underlayment, making it less suitable for areas exposed to high humidity or water. Cement-based underlayments excel in moisture resistance due to their dense, non-porous structure, which prevents water absorption and reduces the risk of mold or swelling. For applications requiring enhanced durability against moisture, cement-based underlayment is the preferred choice to ensure long-term performance.

Sound Control and Acoustic Performance

Gypsum-based underlayment offers superior sound control by effectively reducing impact noise and airborne sound transmission due to its dense, lightweight composition. Cement-based underlayment tends to be heavier and less effective at dampening sound vibrations, resulting in lower acoustic performance in residential and commercial settings. For enhanced acoustic insulation, gypsum underlayments are preferred in applications requiring quieter indoor environments and compliance with sound rating standards.

Application Areas and Suitable Substrates

Gypsum-based underlayment is ideal for interior applications such as residential and commercial floors due to its lightweight nature and fast drying time, making it suitable for substrates like concrete, plywood, and existing ceramic tile. Cement-based underlayment offers superior moisture resistance and durability, making it appropriate for wet areas, exterior applications, and substrates including concrete slabs, cement terrazzo, and exterior-grade plywood. The choice between gypsum and cement underlayment depends on environmental exposure and substrate compatibility to ensure long-lasting flooring performance.

Cost Analysis: Gypsum vs Cement Underlayments

Gypsum-based underlayments typically offer lower material and installation costs compared to cement-based underlayments, making them a cost-effective choice for many flooring projects. Cement underlayments generally incur higher expenses due to longer curing times, increased labor, and more intensive preparation requirements. Budget-conscious construction projects often favor gypsum underlayments for their efficiency and reduced total cost of ownership.

Environmental Impact and Sustainability

Gypsum-based underlayment offers a lower carbon footprint compared to cement-based underlayment due to its naturally occurring mineral composition and reduced energy-intensive manufacturing process. Its biodegradability enhances sustainability by minimizing landfill waste, while cement-based underlayment often involves higher CO2 emissions and longer curing times that contribute to greater environmental impact. Opting for gypsum underlayment supports eco-friendly construction with improved recyclability and resource efficiency.

Choosing the Right Underlayment for Your Project

Gypsum-based underlayment offers faster drying times and smoother finishes compared to cement-based options, making it ideal for interior installations where time efficiency and surface quality are priorities. Cement-based underlayment provides superior moisture resistance and strength, suitable for areas prone to humidity or heavy traffic, such as bathrooms and commercial spaces. Selecting the right underlayment hinges on project requirements like drying time, moisture exposure, and desired durability to ensure optimal performance and longevity.

Gypsum-based underlayment vs Cement-based underlayment Infographic

materialdif.com

materialdif.com