Gypsum sheetrock offers faster installation and smoother finishes compared to traditional lath and plaster, making it a preferred choice for modern construction. It provides superior fire resistance and soundproofing properties while requiring less maintenance over time. The cost-effectiveness and ease of repair further distinguish gypsum sheetrock as a practical alternative to the labor-intensive lath and plaster method.

Table of Comparison

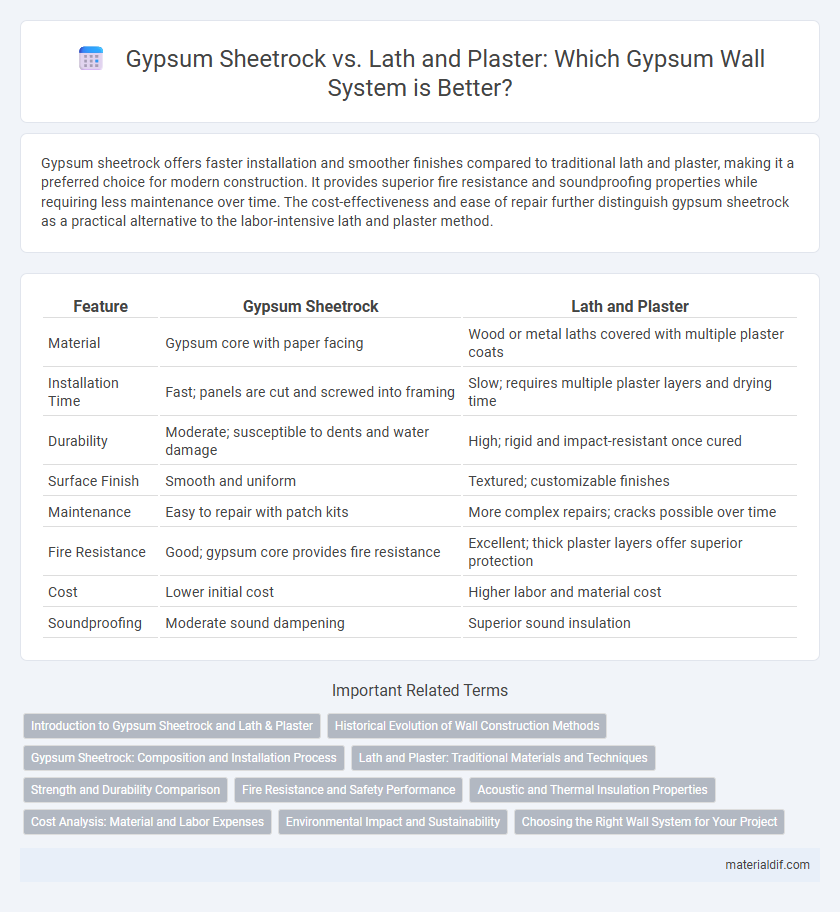

| Feature | Gypsum Sheetrock | Lath and Plaster |

|---|---|---|

| Material | Gypsum core with paper facing | Wood or metal laths covered with multiple plaster coats |

| Installation Time | Fast; panels are cut and screwed into framing | Slow; requires multiple plaster layers and drying time |

| Durability | Moderate; susceptible to dents and water damage | High; rigid and impact-resistant once cured |

| Surface Finish | Smooth and uniform | Textured; customizable finishes |

| Maintenance | Easy to repair with patch kits | More complex repairs; cracks possible over time |

| Fire Resistance | Good; gypsum core provides fire resistance | Excellent; thick plaster layers offer superior protection |

| Cost | Lower initial cost | Higher labor and material cost |

| Soundproofing | Moderate sound dampening | Superior sound insulation |

Introduction to Gypsum Sheetrock and Lath & Plaster

Gypsum sheetrock and lath and plaster represent two distinct interior wall finishes, with gypsum sheetrock consisting of large, prefabricated panels made from gypsum core pressed between paper facings. Lath and plaster involves a traditional technique where wooden or metal laths are nailed to wall studs, then coated with multiple layers of wet plaster for a durable, textured surface. Gypsum sheetrock offers faster installation and smoother walls, while lath and plaster provide greater sound insulation and finer detail for historic restoration.

Historical Evolution of Wall Construction Methods

Gypsum sheetrock emerged in the early 20th century as a faster and more cost-effective alternative to traditional lath and plaster, revolutionizing wall construction methods. Lath and plaster, dating back to Roman architecture, involved layering wooden laths with wet plaster, offering durability but requiring labor-intensive application and longer drying times. The shift to gypsum sheetrock accelerated construction timelines and standardized interior wall finishes, marking a significant evolution in building technology.

Gypsum Sheetrock: Composition and Installation Process

Gypsum Sheetrock consists primarily of a core of gypsum plaster pressed between two thick sheets of paper, offering a smooth and uniform surface ideal for interior walls and ceilings. The installation process involves cutting the sheets to size, fastening them to wall studs or ceiling joists using screws or nails, and finishing with joint compound to create seamless joints. Compared to lath and plaster, Sheetrock significantly reduces installation time and labor while providing enhanced fire resistance and soundproofing properties.

Lath and Plaster: Traditional Materials and Techniques

Lath and plaster is a traditional wall construction method involving wooden strips (laths) nailed to wall studs, which are then coated with multiple layers of wet plaster to create a solid, durable surface. This technique offers superior sound insulation and fire resistance compared to gypsum sheetrock, as the dense plaster layers absorb sound and resist heat more effectively. Despite its labor-intensive process, lath and plaster provides a timeless aesthetic and can be repaired more easily in historic homes, preserving architectural authenticity.

Strength and Durability Comparison

Gypsum sheetrock offers superior strength and durability compared to traditional lath and plaster due to its uniform composition and resistance to cracking. Sheetrock panels are engineered to withstand impact and moisture better, reducing maintenance and repair needs over time. In contrast, lath and plaster systems are more prone to developing cracks and require more frequent upkeep, making gypsum sheetrock the preferred choice for long-lasting wall finishes.

Fire Resistance and Safety Performance

Gypsum sheetrock offers superior fire resistance compared to traditional lath and plaster due to its non-combustible core made of calcium sulfate dihydrate, which slows heat transfer and provides effective fire protection. Its consistent thickness and factory-controlled manufacturing reduce the risk of gaps and weak points, enhancing overall safety performance in fire-prone environments. Fire ratings for gypsum board typically exceed those of lath and plaster assemblies, making it a preferred choice in commercial and residential fire-resistance applications.

Acoustic and Thermal Insulation Properties

Gypsum sheetrock offers superior thermal insulation compared to lath and plaster due to its uniform density and integrated core materials, which reduce heat transfer efficiently. Acoustic properties of gypsum sheetrock surpass lath and plaster by providing better sound attenuation through its dense, layered structure that minimizes sound vibration. Lath and plaster, while traditional, tend to have gaps and uneven surfaces that compromise both soundproofing and thermal resistance.

Cost Analysis: Material and Labor Expenses

Gypsum sheetrock typically costs between $10 to $15 per 4x8-foot panel, with labor expenses averaging $1.50 to $3.00 per square foot, making it more affordable than lath and plaster, which can range from $3 to $8 per square foot for materials alone. Labor for lath and plaster installation often exceeds $6 per square foot due to its time-intensive application and skilled workmanship requirements. Overall, gypsum sheetrock offers significant savings in both material and labor costs, making it a cost-effective choice for modern interior wall finishes.

Environmental Impact and Sustainability

Gypsum sheetrock offers superior environmental benefits compared to traditional lath and plaster due to its lower embodied energy and higher recyclability rates. It generates less construction waste and often contains recycled gypsum, reducing the demand for natural resources. In contrast, lath and plaster involve more labor-intensive processes and materials that typically have a larger carbon footprint and limited recyclability.

Choosing the Right Wall System for Your Project

Gypsum sheetrock offers faster installation and smoother finishes compared to traditional lath and plaster, making it ideal for modern construction projects seeking efficiency and cost-effectiveness. Lath and plaster provide superior sound insulation and durability, which may benefit historic renovation or high-end residential projects requiring enhanced acoustic performance. Evaluate project requirements such as budget, timeline, finish quality, and historic preservation to determine the most suitable wall system.

Gypsum sheetrock vs Lath and plaster Infographic

materialdif.com

materialdif.com